Preparation method for magnetic carbonaceous solid acid catalyst

A solid acid catalyst and magnetic technology, applied in the field of carbon materials, can solve the problems of poor catalytic activity, time-consuming and cumbersome preparation process, and insufficiently developed pore structure, and achieve the effects of simple preparation method, good repeatability and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of iron-based complexes

[0040] Soak 1.2 kg of cleaned banana peel fragments in 1.8 L of 1.0 mol / L ferric chloride aqueous solution and heat to dry at 80° C. to obtain a gray-black iron-based composite.

[0041] 2. Preparation of magnetic porous carbon materials

[0042] The obtained iron-based composite was calcined at 650° C. for 3 hours under the protection of an inert gas, washed with distilled water and absolute ethanol in sequence, and dried at 80° C. for 12 hours to obtain a magnetic porous carbon material.

[0043] 3. Preparation of magnetic carbonaceous solid acid catalyst

[0044] The obtained magnetic porous carbon material was mixed with fuming sulfuric acid at a mass ratio of 1:15, ultrasonically treated for 30 minutes, followed by sulfonation treatment at 120°C for 12 hours under airtight conditions, then cooled to room temperature, and slowly added to 500mL of distilled water, Filter, wash with distilled water until no sulfate ions exist...

Embodiment 2

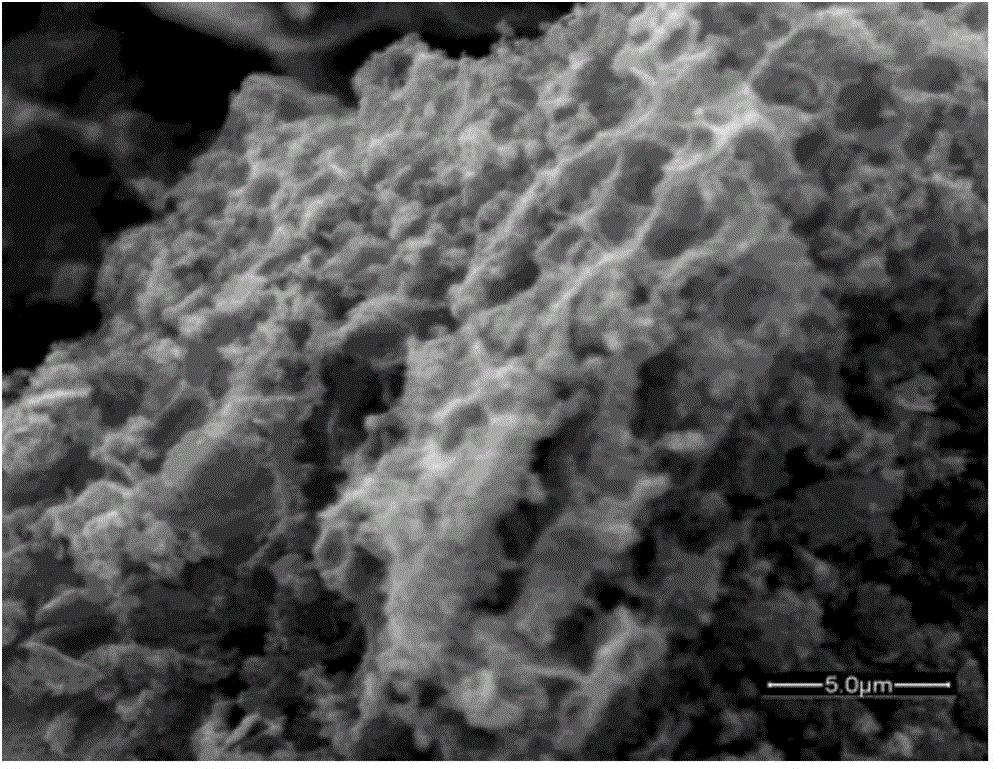

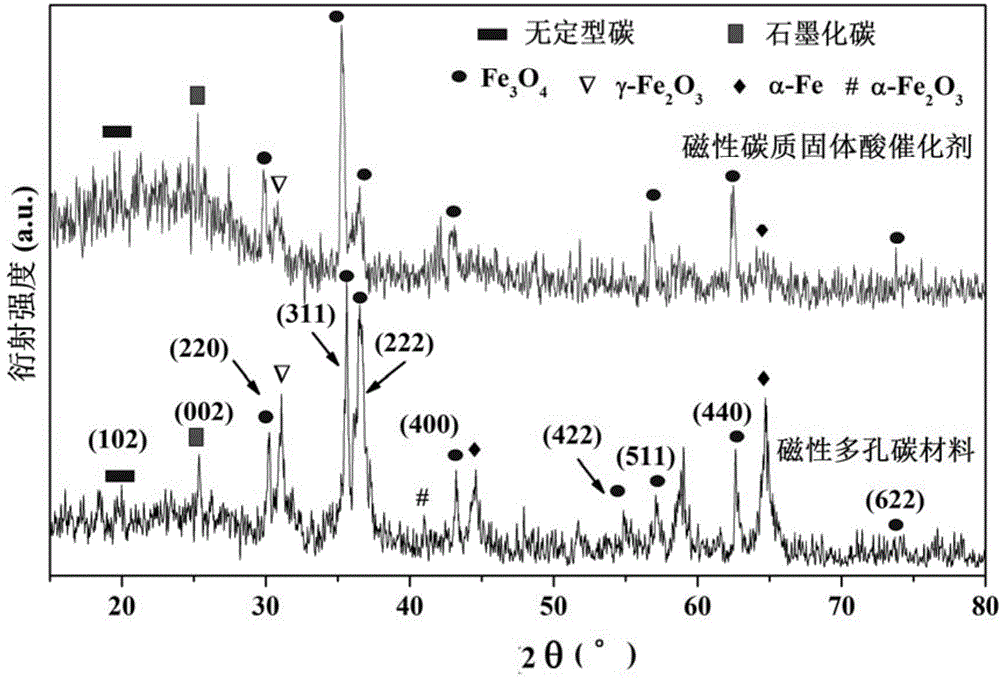

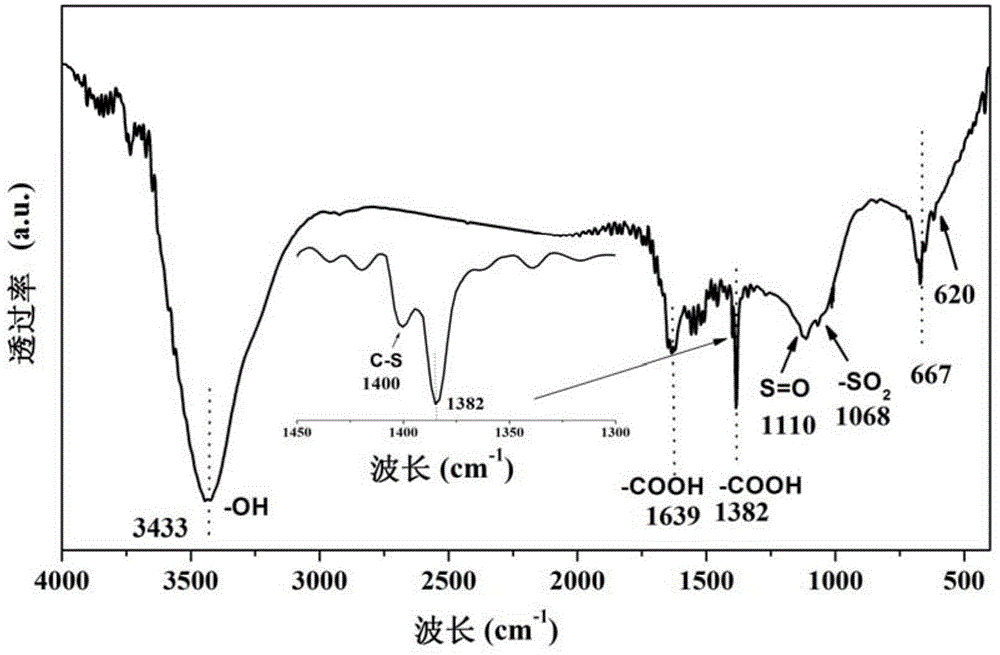

[0047] In the preparation step 1 of the iron-based composite of the present embodiment, the concentration of the ferric chloride aqueous solution used is 0.8mol / L, and other steps are the same as in Example 1, and a magnetic carbonaceous solid acid catalyst is prepared, which presents a porous structure ( See Figure 4 ). Depend on Figure 5 It can be seen that both the obtained magnetic porous carbon material and the magnetic carbonaceous solid acid catalyst are composed of carbon-Fe 3 o 4 species composition. Infrared spectroscopy showed (see Image 6 ), the surface of the resulting magnetic carbonaceous solid acid catalyst contains sulfonic acid groups.

Embodiment 3

[0049] In the step 1 of preparing the iron-based composite in this embodiment, the concentration of the ferric chloride aqueous solution used is 0.6 mol / L, and the other steps are the same as in the embodiment 1 to prepare a magnetic carbonaceous solid acid catalyst. Depend on Figure 7 It can be seen that the obtained magnetic carbonaceous solid acid catalyst presents a nanosheet-like mesoscopic structure, and Fe with different particle sizes 3 o 4 The nano crystallites are evenly distributed in the carbon skeleton. Energy spectrum analysis also shows that the magnetic carbonaceous solid acid catalyst is mainly composed of C, O and Fe elements ( Figure 8 ). Figure 9-10 It shows that the prepared magnetic carbonaceous solid acid catalyst not only retains the Fe2p species well, but also the sulfonic acid group is successfully modified. Fe2p photoelectron spectroscopy ( Figure 11 ) further reveals that the magnetic substance is Fe 3 o 4 instead of Fe 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com