Method for reduction of graphene oxide by metal/tea polyphenol as reducing agent

A technology of tea polyphenols and reducing agents, which is applied in the field of metal/tea polyphenols as reducing agents to reduce graphene oxide, can solve the problems of long preparation period, complex process, high toxicity of reducing agents, etc., achieve good reducibility and improve electrical conductivity Performance, the effect of improving the reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

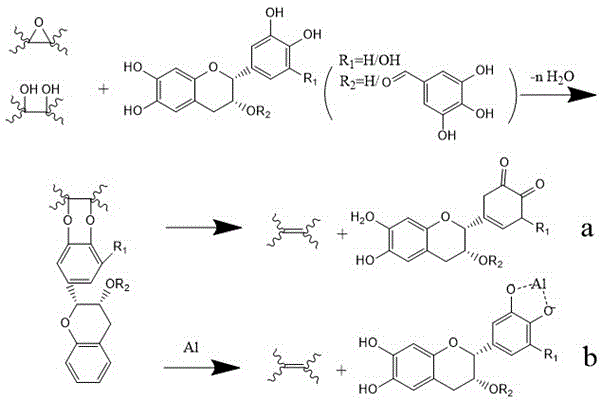

Method used

Image

Examples

Embodiment 1

[0022] Graphite oxide was prepared by the Hummers method, and 230ml of concentrated sulfuric acid with a mass fraction of 98% was slowly added to a 1000ml three-necked flask, and 10g of original graphite and 5g of NaNO 3 Slowly add concentrated sulfuric acid, stir at a low temperature of 5°C to ensure thorough mixing, and slowly add 30g KMnO in batches after 30 minutes 4 , reacted for 2 hours; then moved the three-necked flask into a 35°C water bath for medium-temperature reaction, and continued to stir for 30 minutes; slowly added 460ml of deionized water to the three-necked flask for dilution, and then moved the three-necked flask into a 95°C water bath for high-temperature reaction, and continued to stir for 30 minutes ; the reaction ends, the mixture is moved into the beaker and continues to add deionized water for dilution, adding 25ml mass fraction is 30% H 2 o 2 Solution, after washing several times with deionized water, add a little HCl solution with a mass fraction o...

Embodiment 2

[0025] Adopt the method for embodiment 1 to prepare 100ml concentration and be the graphene oxide dispersion liquid of 3mg / ml, add this solution into 250ml there-necked flask, then add 0.3g tea polyphenols and 1.2g aluminum sheet to the there-necked flask, the size of aluminum sheet is 0.5cm ×0.5cm×1mm, that is, the mass ratio of graphene oxide to tea polyphenols and aluminum is 1:1:4, put the three-neck flask in a water bath at 80°C for 2 hours; after the reaction is completed, the product is centrifugally washed and removed from the dispersion For excess tea polyphenols, remove the precipitate and place it in an oven at 105°C to dry to obtain graphene.

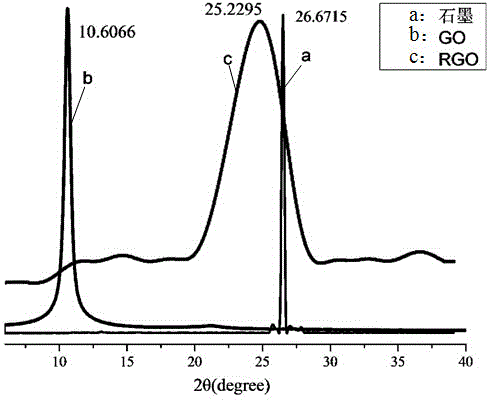

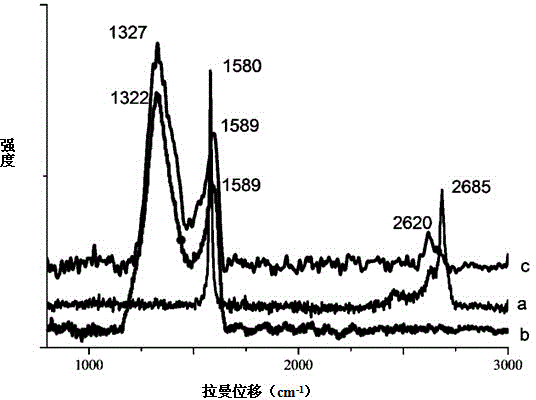

[0026] figure 2 Curve c in middle shows the XRD spectrum of graphene. After the reduction of tea polyphenols / aluminum flakes, the interlayer spacing of graphene is reduced from 0.834nm to 0.353nm, which is close to the original graphite interlayer spacing, indicating the removal of oxygen-containing groups. This proves the...

Embodiment 3

[0029] Adopt the method for embodiment 2 to prepare graphene, the difference is that the quality of aluminum sheet is changed from 1.2g to 0.3g, that is, the mass ratio of graphene oxide, tea polyphenols and aluminum is 1:1:1; As shown in Table 1, the square resistance of the graphene film has reached 279.67Ω / sq, which is 30.2% lower than that of Comparative Example 1, indicating that the addition of reducing aluminum flakes in the reducing system can improve the conductivity of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com