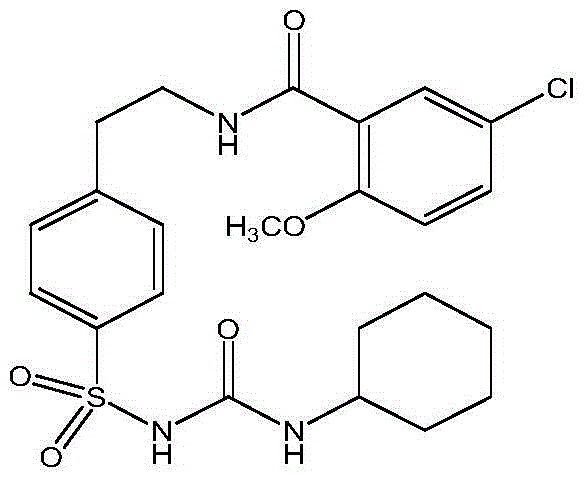

Micronized glibenclamide and composition thereof

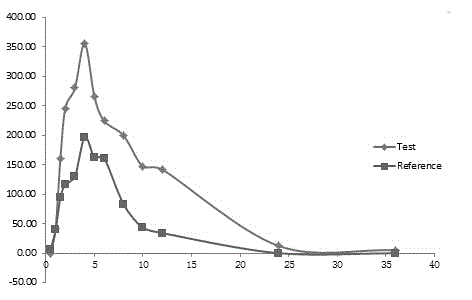

A technology of micronization and composition, applied in the field of medicine, can solve the problems of high energy, shortened time to peak blood concentration of glibenclamide, and life-threatening problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

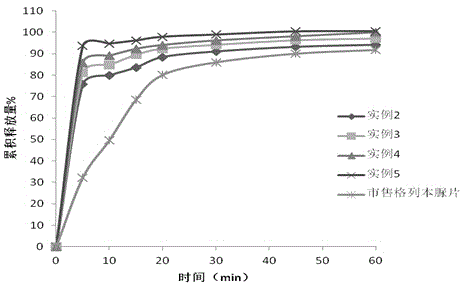

[0042] Take an appropriate amount of unmicronized and micronized glibenclamide raw materials, and investigate whether the raw materials of two particle sizes are in 0.1M hydrochloric acid solution, pH4.5 acetate buffer, pH6.8 phosphate buffer, pH7.4 The saturation solubility in phosphate buffer and pH8.5 phosphate buffer, the test results are shown in Table 1.

[0043] The glibenclamide was injected into the ultrafine pulverizer and crushed by high-speed airflow. The working pressure of the superfine pulverizer was 2.3 MPa, the internal working temperature was 0-10° C., and the pulverization time was 20 minutes. The obtained micronized glibenclamide with a particle size of 0.5 μm-5 μm accounted for 75%.

[0044] Table 1 Saturation solubility test results of glibenclamide raw materials in buffer solutions with different pH values

[0045]

[0046] From the test results, it can be known that glibenclamide bulk drug is insoluble in 0.1M hydrochloric acid solution, and its sol...

Embodiment 2

[0048]

[0049] Mix the micronized glibenclamide powder with Tween 80, microcrystalline cellulose and lactose according to the method of equal addition, and then mix it with sodium carboxymethyl starch, add 25ml of starch slurry containing 5% to make granules, and heat at 60°C Ventilate and dry, granulate, add magnesium stearate, mix evenly, and compress into tablets.

Embodiment 3

[0051]

[0052] Mix the micronized glibenclamide powder with Tween 80, microcrystalline cellulose and lactose according to the method of equal addition, and then mix it with sodium carboxymethyl starch, add 25ml of starch slurry containing 5% to make granules, and heat at 60°C Ventilate and dry, granulate, add magnesium stearate, mix evenly, and compress into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com