A microwave-enzymatic coupled method for degrading chitosan

A technology of chitosan and chitosan solution is applied in the field of chitosan preparation, which can solve the problems of long degradation reaction period, poor product uniformity and high cost, and achieve the effects of low cost, low cost and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

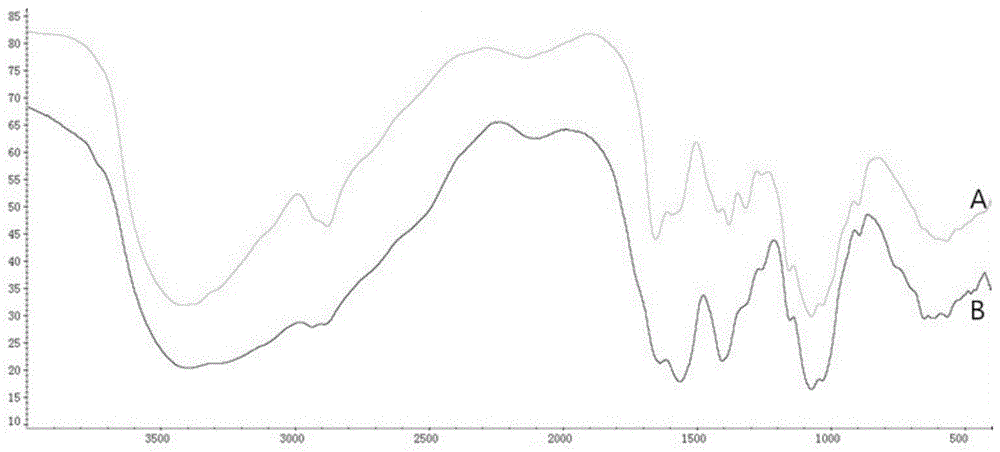

Image

Examples

Embodiment 1

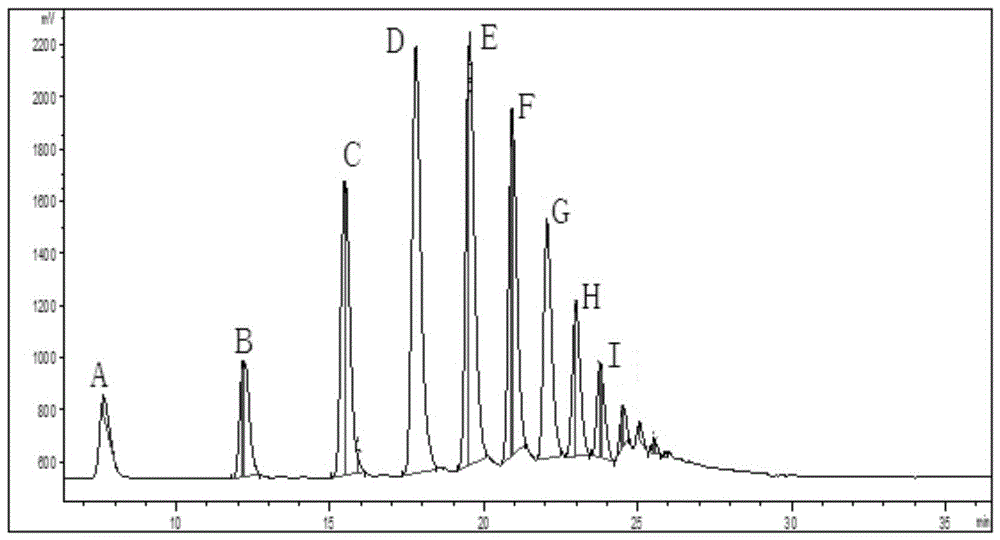

[0017] Prepare 100ml of pH=5 buffer solution with acetic acid and sodium acetate, and add 1g of high molecular chitosan (relative molecular weight (hereinafter abbreviated as Mw) 1.8×10 to the buffer solution 6 Da), the number-average molecular weight is 5.0×105Da-5.0×106Da) by HPLC, and the chitosan solution is prepared by stirring thoroughly; then 0.03g cellulase is added to the chitosan solution, and the chitosan is mixed evenly after stirring. Pour the glycan solution into the reaction flask, then put the reaction flask into the microwave reactor, and pour nitrogen into the reaction flask, control the temperature at 55℃, the microwave power 600W for degradation reaction, and the microwave will be heated to 100℃ after 10 minutes. Enzyme inactivation, the inactivation reaction time is 10-15min; adjust the pH value of the solution after the reaction to 7-8 with 1mol / L sodium hydroxide solution, and then filter to remove the precipitate, after the filtrate is dialyzed to remove s...

Embodiment 2

[0019] Prepare 100ml of pH=5 buffer solution with acetic acid and sodium acetate, add 1g high molecular chitosan (Mw=1.8×10) to the buffer solution 6 Da, number average molecular weight 5.0×105Da-5.0×106Da), stir well to prepare a chitosan solution; then add 0.03g cellulase to the chitosan solution, stir evenly, pour the solution into the reaction flask, and then The reaction flask was put into a microwave reactor, and nitrogen was introduced into the reaction flask. The temperature was controlled at 55°C and the microwave power was 600W for degradation reaction. After 60 minutes, the microwave was heated to 100°C to inactivate the enzyme. The inactivation reaction time was 10- 15min; Adjust the pH value of the reacted solution to 7-8 with 1mol / L sodium hydroxide solution, then filter to remove the precipitate, the filtrate is dialysis to remove salt ions and freeze-dried to obtain low molecular weight chitosan, yield Is 82%; measured by high performance liquid chromatography, t...

Embodiment 3

[0021] The steps of the method for degrading chitosan in this example are the same as those in Example 1 and Example 2. The number average molecular weight of high molecular weight chitosan is 5.0×10 5 Da-5.0×10 6 Da, other relevant experimental data are shown in Table 1:

[0022]

[0023]

[0024] Table 1

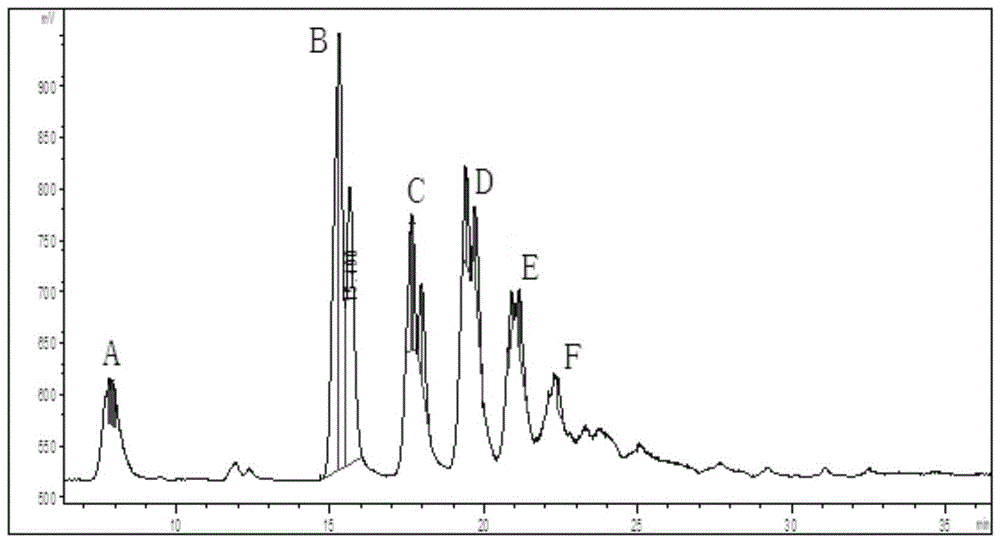

[0025] Among them, the low molecular weight chitosan in Example 10 was measured by high performance liquid chromatography for its degree of polymerization. It mainly contained trisaccharides to hexasaccharides. image 3 As shown; the comparison between the control example and the example shows that the yield of enzymatic chitosan at room temperature is significantly lower than the yield of enzymatic chitosan under microwave heating conditions, so the microwave-enzymatic coupling degraded shell designed by the present invention The glycan method has higher degradation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com