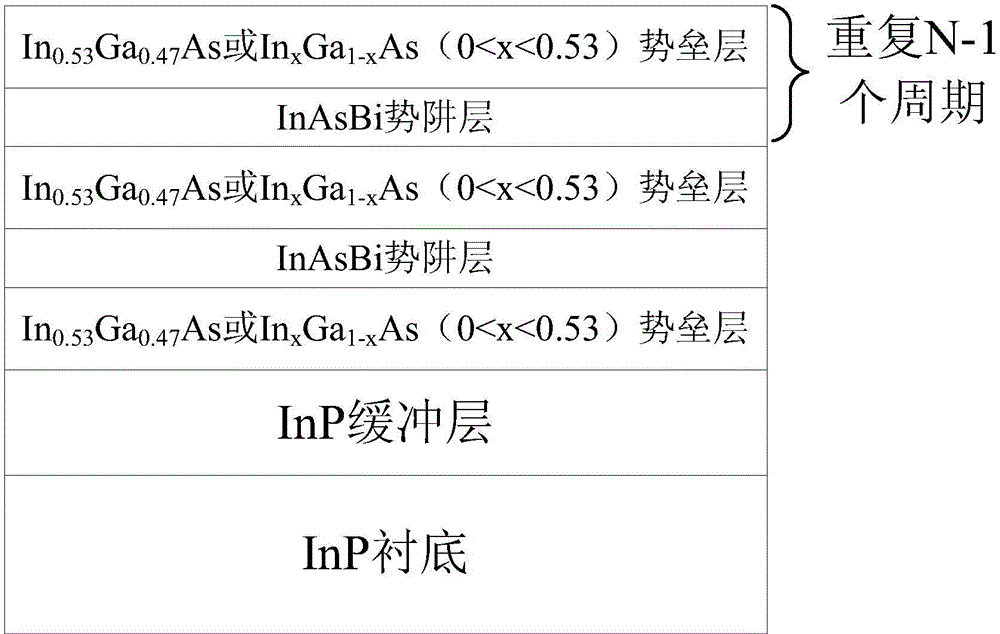

InP-based intermediate infrared InAsBi quantum well structure

A quantum well and infrared technology, applied in phonon exciters, laser parts, electrical components, etc., can solve the problem that the light emission wavelength is difficult to break through 3 microns, and achieve high electro-optical conversion efficiency, excellent substrate quality, and threshold current low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

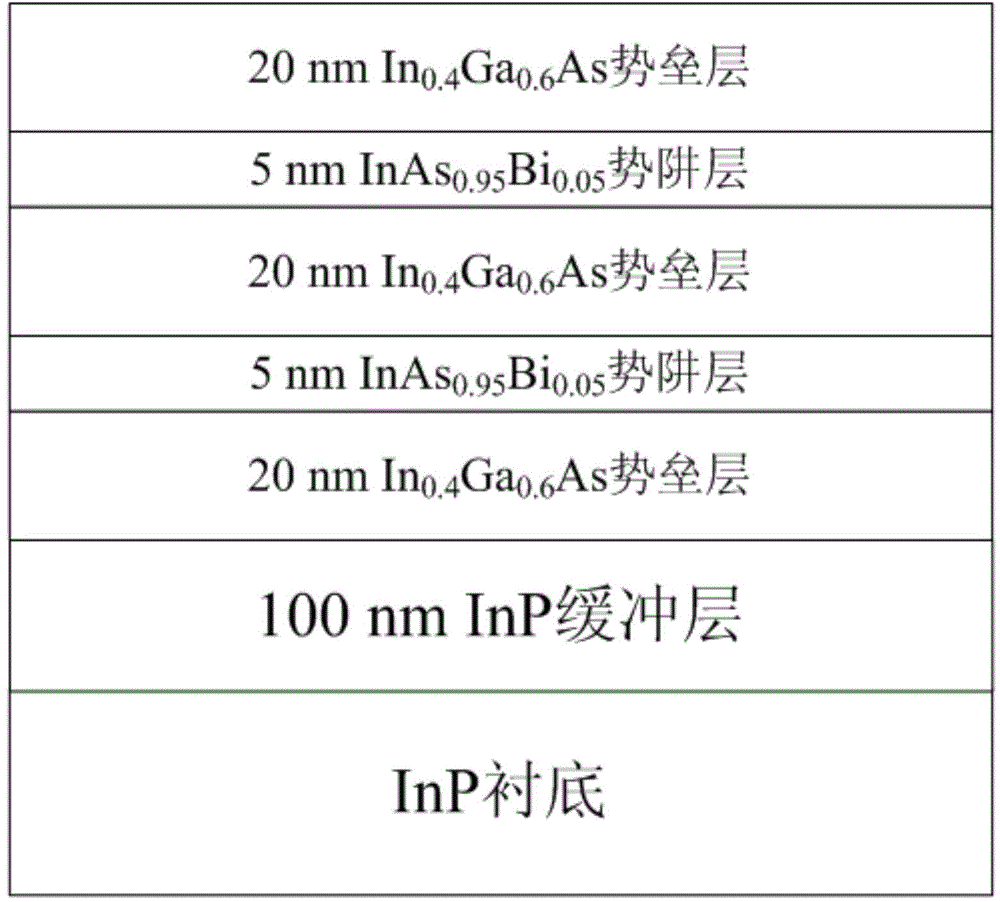

Embodiment 1

[0019] To prepare InAs with an InP-based emission wavelength of 3.1 microns 0.95 Bi 0.05 Double quantum well as an example:

[0020] (1) To grow InAs on an InP substrate 0.95 Bi 0.05 Double quantum well structure, first grow a 100nm InP buffer layer;

[0021] (2) grow a layer of 20nm thick In 0.4 Ga 0.6 As material as a barrier layer;

[0022] (3) Grow a layer of InAs with a thickness of 5nm 0.95 Bi 0.05 material as a potential well layer;

[0023] (4) Grow a layer of In with a thickness of 20nm again 0.4 Ga 0.6 As material as a barrier layer;

[0024] (5) A layer of InAs with a thickness of 5nm is grown again 0.95 Bi 0.05 material as a potential well layer for the second quantum well;

[0025] (6) Finally grow a layer of In with a thickness of 20nm 0.4 Ga 0.6 The As material is used as a barrier layer to complete the growth of the double quantum well structure, and the quantum well emits light at room temperature with a wavelength of about 3.1 microns.

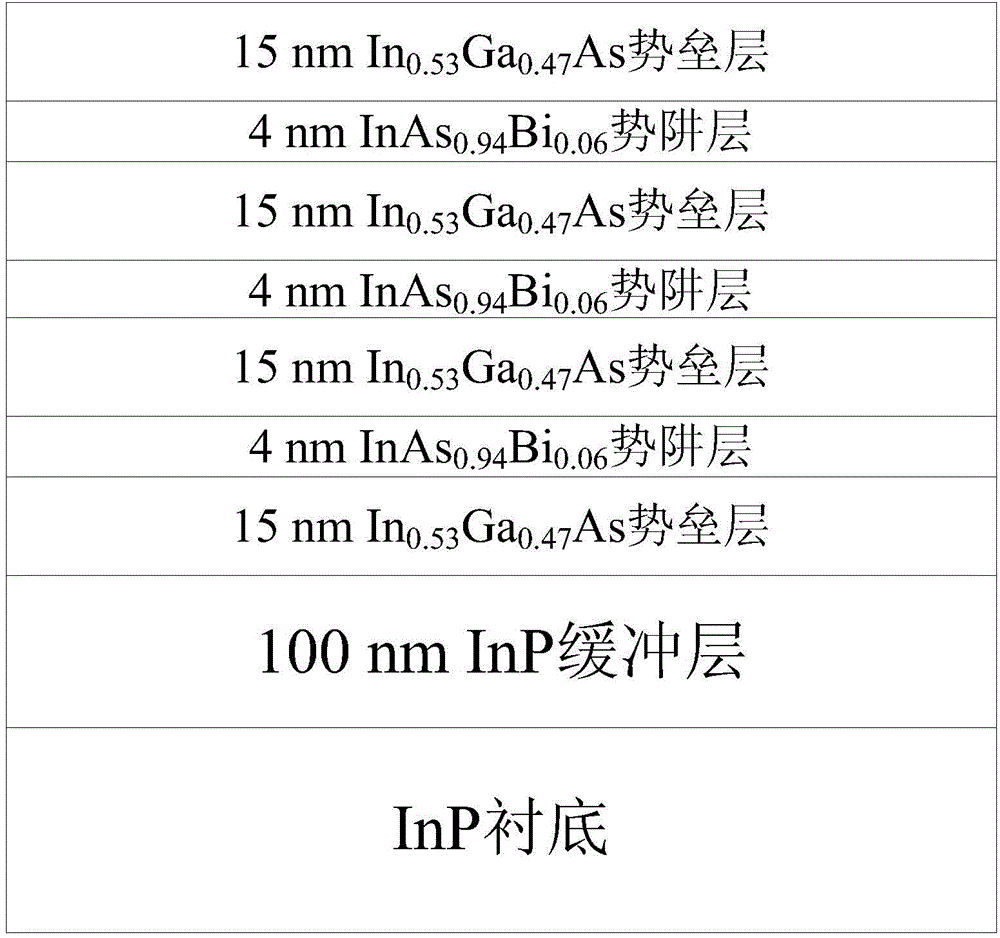

Embodiment 2

[0027] To prepare InAs with an InP-based emission wavelength of 3.0 microns 0.94 Bi 0.06 Three quantum wells as an example:

[0028] (1) To grow InAs on an InP substrate 0.94 Bi 0.06 Three quantum well structure, first grow a 100nm InP buffer layer;

[0029] (2) grow a layer of 15nm thick In 0.53 Ga 0.47 As material as a barrier layer;

[0030] (3) grow a layer of 4nm thick InAs 0.94 Bi 0.06 material as a potential well layer;

[0031] (4) grow a layer of 15nm thick In again 0.53 Ga 0.47 As material as a barrier layer;

[0032] (5) The above-mentioned (3) and (4) processes are repeated twice in a cycle, that is, the growth of the three-quantum well structure is completed, and the emission wavelength of the quantum wells at room temperature is about 3.0 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com