Intelligent power module and manufacturing method thereof

A technology of intelligent power modules and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. Effects of long-term reliability, improved corrosion resistance, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

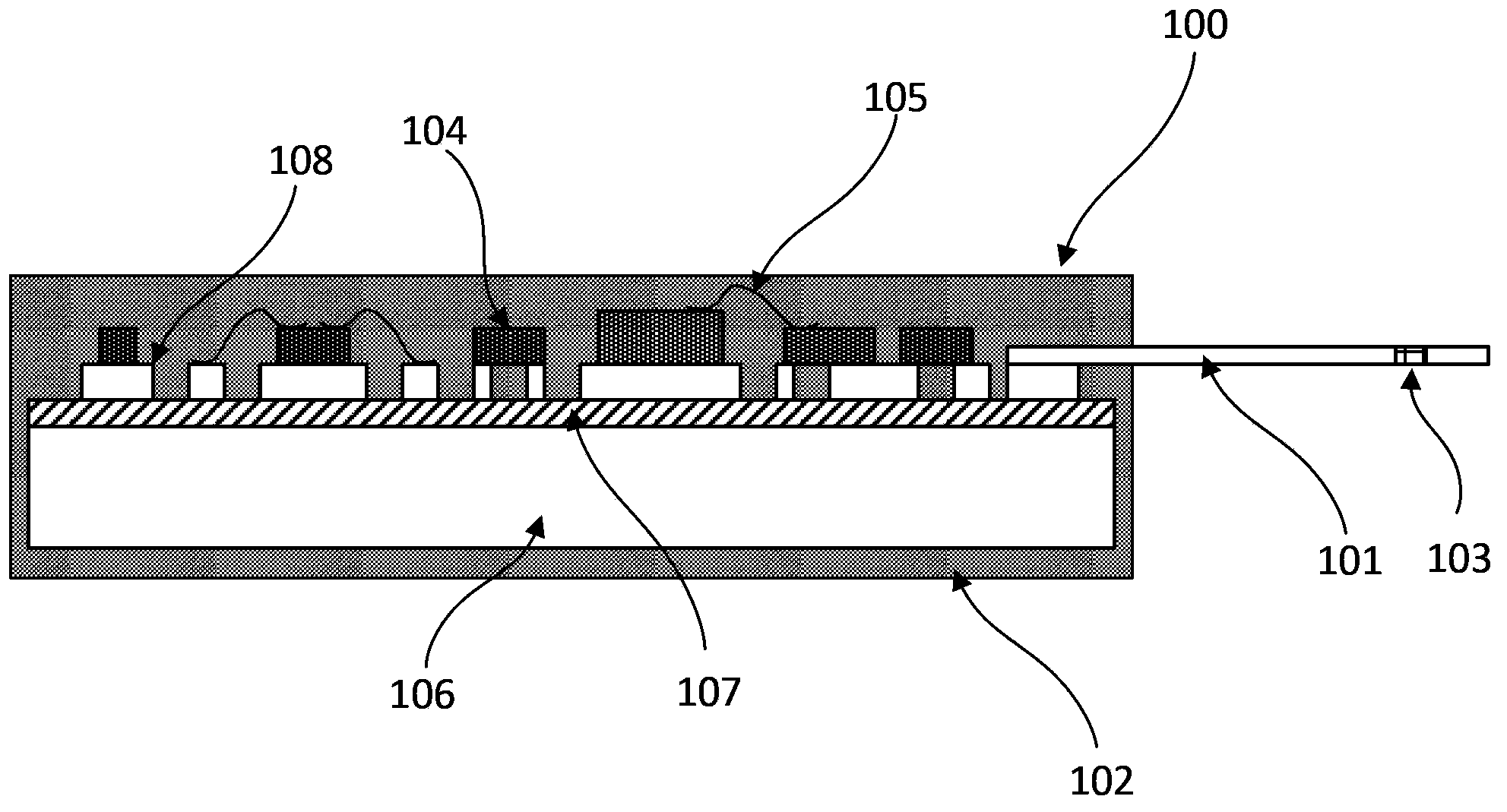

[0033] 2(A), 2(B) and 2(C), the intelligent power module includes pins 11 , sealing layer 12 , circuit elements 14 , bonding wires 15 , substrate 16 , insulating layer 17 , and circuit wiring 18 .

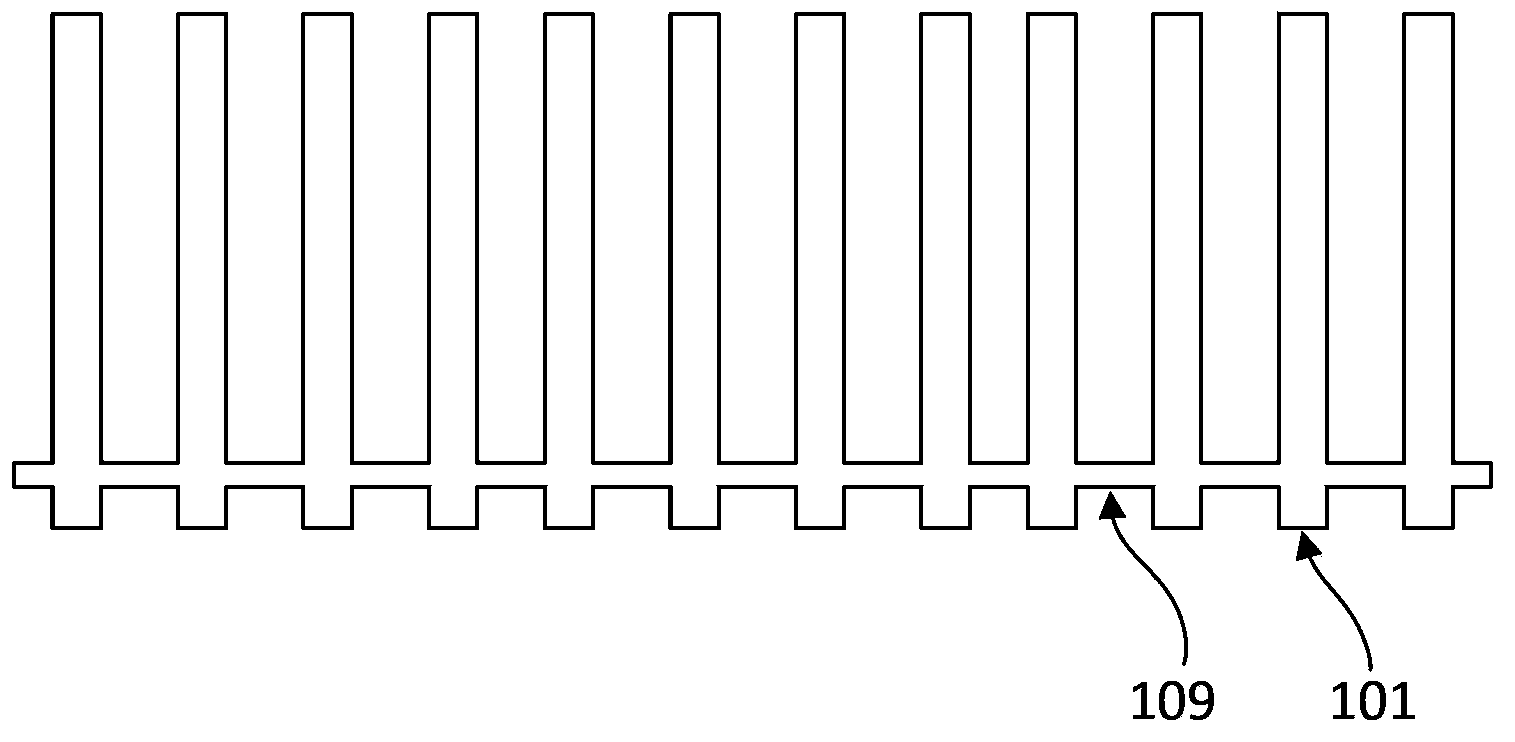

[0034] The insulating layer 17 covers the upper surface of the substrate 16 , the circuit wiring 18 is disposed on the surface of the insulating layer 17 , and the circuit element 14 is arranged at a corresponding position of the circuit wiring 18 . The circuit wiring 18 includes element pads for arranging the circuit elements 14, lead pads 18A for soldering the pins 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com