Process for treating fermentation industrial wastewater based on activated aerobic sludge-artificial ecological wetland composite system

A technology for activated aerobic sludge and industrial wastewater, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve high investment and operating costs and performance requirements of treatment equipment High, limited processing capacity and other issues, to achieve the effect of low input cost, good comprehensive decontamination effect, low operating cost and management cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

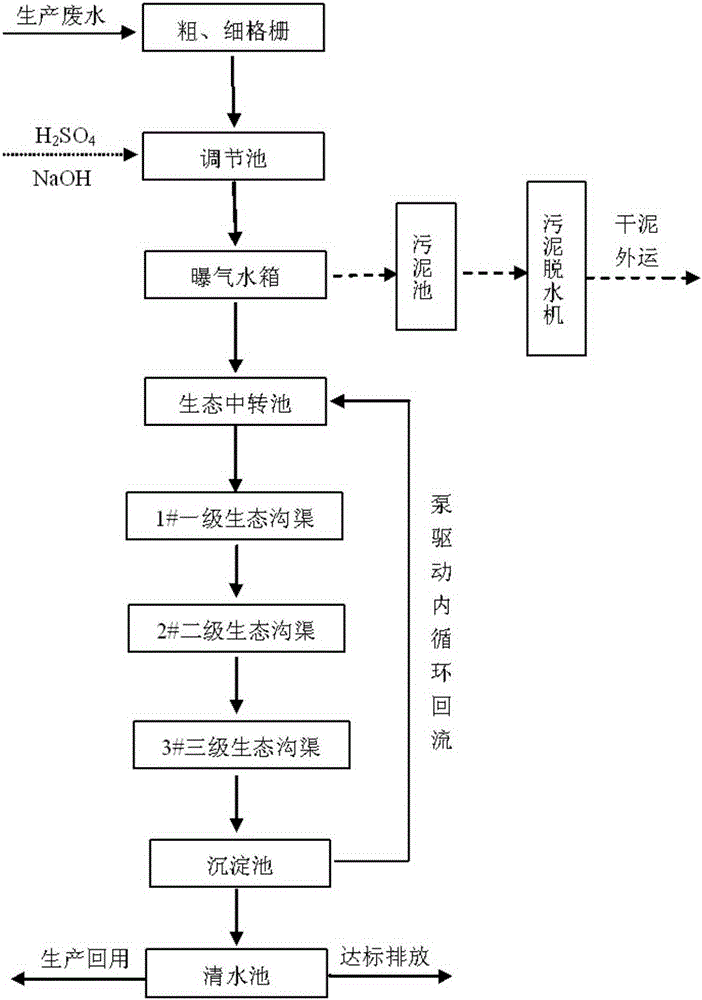

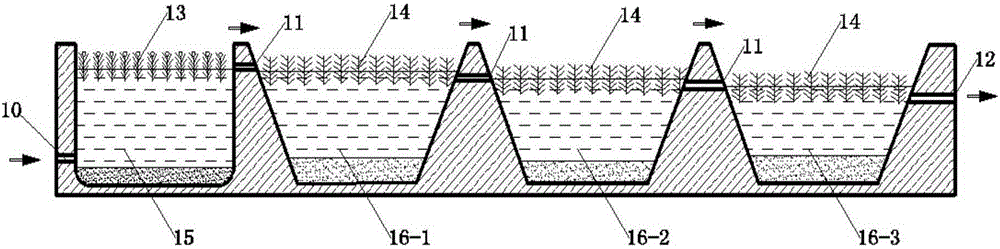

[0037] process such as figure 1 As shown, 30t of yeast fermentation industrial wastewater is processed daily, including extraction and concentration wastewater, tank and equipment cleaning wastewater, etc. Wastewater is rich in protein, amino acid, sugar and other organic matter and various trace elements, COD is as high as 3500mg / L, ammonia nitrogen value exceeds 400mg / L, and pH value fluctuates in the range of 4-11.

[0038] The treatment process is as follows: the fermentation industrial wastewater is filtered by thick and thin grids and then flows into the adjustment pool, the area of the adjustment pool is 40m 2 , 2m deep, equipped with an acid-base supplementary device (10mol / L H 2 SO 4 and 30% liquid alkali solution) to adjust the pH range to between 7 and 8.

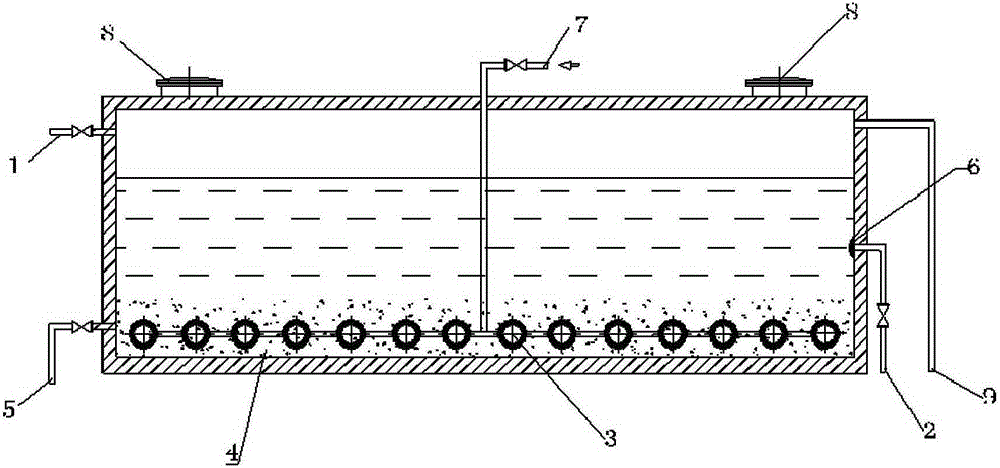

[0039] The wastewater pretreated in the regulating tank is pumped into the aeration box through the sewage lift pump, and the aeration box is as follows: figure 2 structure shown.

[0040] Install four se...

Embodiment 2

[0051] Daily treatment of 20t E. coli fermentation industrial wastewater, including extraction and concentration wastewater, tank equipment washing wastewater, etc. Since the E. coli culture medium contains a large amount of organic nitrogen and carbon sources, the total COD in the discharged industrial wastewater is above 5000mg / L, the ammonia nitrogen value is above 500mg / L, and the total phosphorus reaches 100mg / L.

[0052] The treatment process is as follows: the fermentation industrial wastewater is filtered by thick and thin grids and then flows into the adjustment pool, the area of the adjustment pool is 30m 2 , 2m deep, equipped with an acid-base supplementary device (10mol / L H 2 SO 4 and 30% liquid alkali solution) to adjust the pH range to between 7 and 8.

[0053] The wastewater pretreated in the regulating tank is pumped into the aeration tank through the sewage lifting pump, and the structure of the four sets of aeration tanks is the same as that of the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com