Waterborne fluorocarbon coating for corrosion prevention as well as preparation method and application thereof

A fluorocarbon coating, water-based technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problem of improving the acid and alkali resistance and salt spray resistance of the coating film, and the gap between water resistance and acid and alkali resistance of single-component thermoplastics Larger, limited cross-linking density and other problems, to achieve the effect of no fire hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

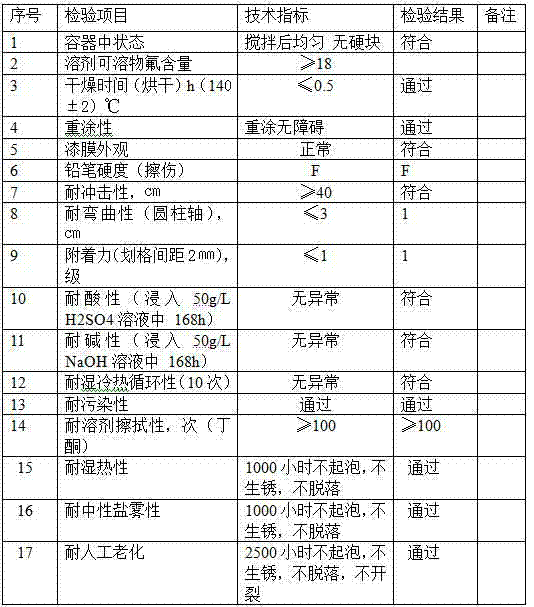

Examples

Embodiment 1

[0036] (1) Put 20 parts by weight of deionized water in a container, and add 75 parts by weight of rutile titanium dioxide and 0.6 parts by weight of BP-187 water-based bentonite (Zhejiang Linan Huate New Material Co., Ltd. Co., Ltd.), 5 parts by weight of wetting and dispersing agent BYK191 (Germany BYK Chemical Co., Ltd.) and 0.2 parts by weight of defoamer 090 (Taiwan Deqian Chemical Co., Ltd.), and then add 120 parts by weight of glass beads to Grinding at a speed of 2000 rpm to a fineness of 35 μm to obtain a titanium white slurry;

[0037] (2) Put 70 parts by weight of water-based fluorocarbon resin (BY-5607 fluorine-modified hydroxyl-containing dispersion of Beijing Baiyuan Chemical Co., Ltd.; solid content 45%, hydroxyl content 2.7%) in a container, and add in sequence under low-speed stirring 9.7 parts by weight of deionized water, 0.2 parts by weight of leveling agent BYK381 (Germany BYK Chemical Co., Ltd.), 0.1 parts by weight of defoamer 090 (Taiwan Deqian Chemical...

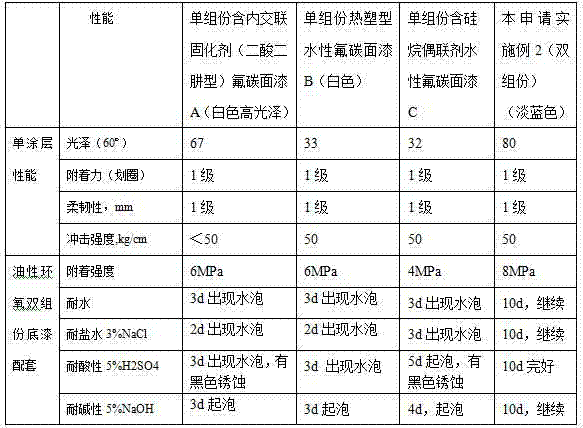

Embodiment 2

[0043] (1) Put 20 parts by weight of deionized water in a container, and add 75 parts by weight of rutile titanium dioxide, 0.6 parts by weight of water-based bentonite, and 5 parts by weight of wetting and dispersing agent BYK191 ( German BYK Chemical Co., Ltd.) and 0.2 parts by weight of defoamer 090 (Taiwan Deqian Chemical Co., Ltd.), after stirring evenly, add 120 parts by weight of glass beads, and grind at a high speed of 2000 rpm to a fineness of 35 μm to obtain Titanium white paste;

[0044] (2) Put 54.5 parts by weight of deionized water in a container, and add 15 parts by weight of wetting and dispersing agent BYK191 (Germany BYK Chemical Co., Ltd.), 30 parts by weight of carbon black in turn under the condition of stirring at a low speed of 400 rpm , 0.3 parts by weight of BP-187 water-based bentonite (Zhejiang Lin'an Huate New Material Co., Ltd.), and 0.2 parts by weight of defoamer 090 (Taiwan Deqian Chemical Co., Ltd.), stir well and then add 120 parts by weight ...

Embodiment 3

[0055] The fluorocarbon coating for the PET film obtained in Example 2 was applied to prepare a coated PET film. The preparation method of described coating PET film follows the following steps:

[0056] (1) Pre-treatment of the steel structure; that is, sandblasting the surface of the steel structure.

[0057] (2) Spray, roll or brush anti-corrosion zinc-rich primer on the pre-treated steel structure;

[0058] (3) The steel structure after the primer is dried at room temperature for more than 8 hours.

[0059] (4) Spray, roll or brush the anti-corrosion cloud iron intermediate paint on the dry zinc-rich primer

[0060] (5) The steel structure after the intermediate paint is dried at room temperature for more than 8 hours

[0061] (6) Mix component A and component B according to the weight ratio of 5:1, add a small amount of deionized water to adjust the viscosity to 30-60 (seconds / 25°C, apply 4# cup), and apply it on the dry micaceous iron intermediate paint Spray, roll o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com