Novel viscosity reducer for viscous oil

A heavy oil viscosity reducer and technology of viscosity reducer, applied in the field of heavy oil viscosity reducer, can solve the problems of high economic cost, complicated operation, insufficient viscosity reduction performance, etc., and achieve good viscosity reduction effect, environmental protection and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

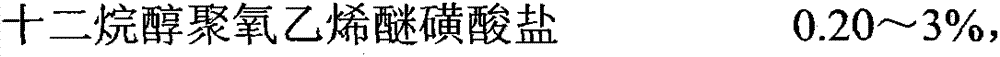

[0022] The specific preparation method of heavy oil viscosity reducer of the present invention:

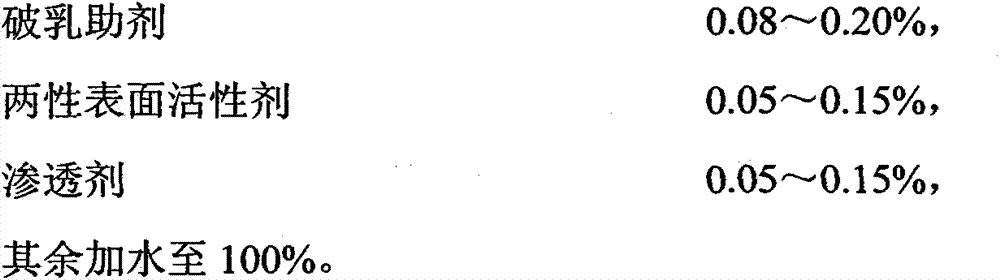

[0023] 1. The synthetic method of polyoxyethylene lauryl ether sulfonate III:

[0024] According to the prior art, it is mainly divided into four steps: first, polyoxyethylene lauryl ether and epichlorohydrin are reacted to obtain product I; in the second step, product I is reacted with NaOH to obtain product II; in the third step, Product II and sodium bisulfite carry out sulfonation reaction, obtain product lauryl alcohol polyoxyethylene ether sulfonate III:

[0025]

[0026] 2. The demulsifiers described in the present invention are ethylene bis (tetradecyl dimethyl ammonium chloride), propylene bis (dodecyl polyoxyethylene ammonium chloride), propylene bis (Dedecylpolyoxyethylene / Polyoxypropylene Chloride / Ammonium Bromide), Ethylene[(Octaamidopropyl Dimethyl / Myristamidopropyl Dimethyl) Chloride / Ammonium Bromide], Butyl One or more of olefinic acid diethylenyl bis(octyldim...

Embodiment 2

[0036] According to the technical scheme of the present invention, the heavy oil viscosity reducer prepared in the present invention is mainly used for heavy oil huff and puff cold recovery, and the specific implementation steps are as follows:

[0037] 1. According to the condition of the oil well, the heavy oil viscosity reducer prepared by the present invention is injected into the formation with a high-pressure pump.

[0038] 2. After the construction is completed, the viscosity of underground crude oil decreases, and oil production can begin.

[0039] 3. After a period of mining, the viscosity of crude oil increases, and it is difficult to recover crude oil. Repeat step 1.

[0040] Repeatedly realize heavy oil huff and puff cold recovery.

Embodiment 3

[0042] Through the heavy oil samples collected on-site in each oil production area of Shengli Oilfield, the heavy oil viscosity reducer prepared by the present invention is used to carry out the viscosity reduction test on the collected heavy oil samples, and the results show that the heavy oil viscosity reducer prepared by the present invention Remarkable viscosity reduction effect.

[0043] Table 1 Viscous reduction effect data of viscous oil viscosity reducer prepared according to the present invention

[0044]

[0045]

[0046] The experimental results of the present invention show that the thick oil viscosity reducer prepared by the present invention can adapt to the viscosity reduction of various heavy oils and has obvious effect, and greatly improves the viscosity reduction rate of heavy oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com