Hollow-structure strontium terbium aluminate luminescent material and preparation method thereof

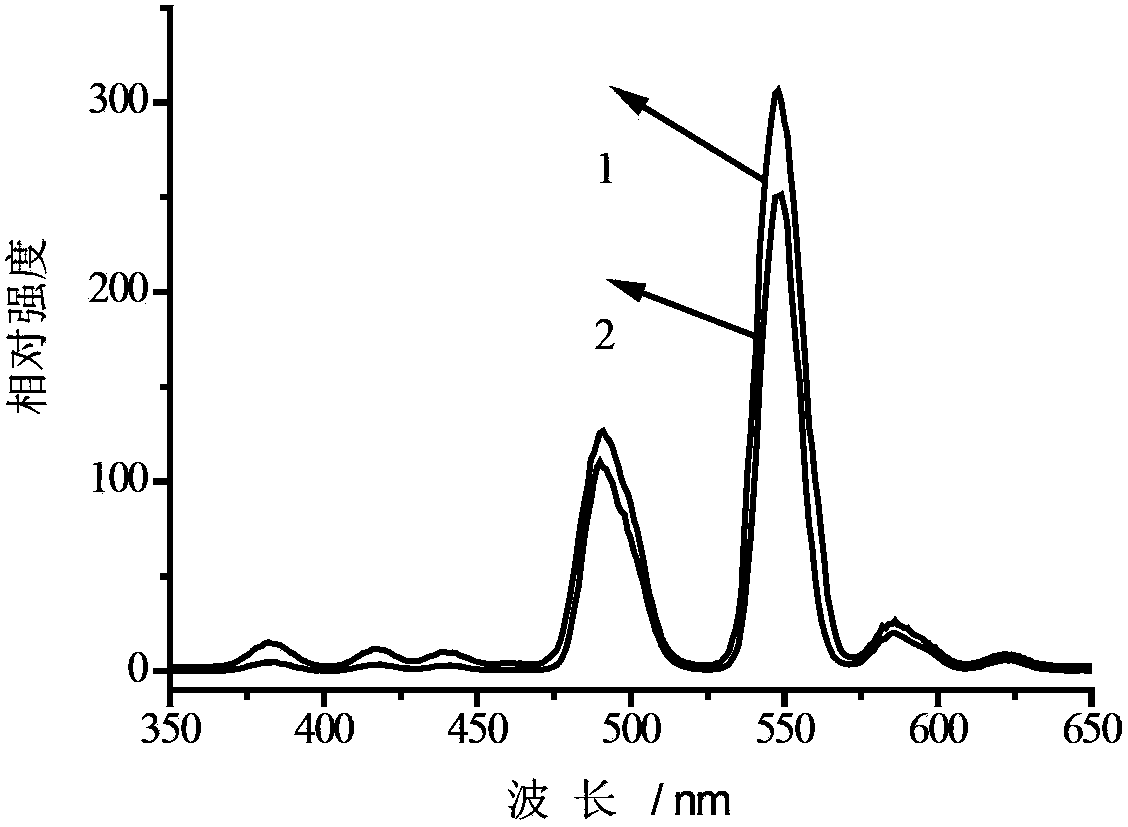

A luminescent material and hollow technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limited light source application and low luminous efficiency, and achieve good luminous performance and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Hollow Structure Sr Coated Metal Nanoparticles 0.9 Al 2 O 4 :Tb 0.1 Cu 1×10 -4:

[0031] Preparation of Cu nanoparticle sol: Weigh 1.6 mg of copper nitrate and dissolve it in 16 mL of ethanol. After it is completely dissolved, add 2 mg of PVP while stirring, and then slowly dropwise add 1 × 0.4 mg of sodium borohydride dissolved in 10 mL of ethanol. 10 -3 4 mL of mol / L sodium borohydride alcoholic solution, continue to stir for 10 min to obtain 20 mL of 4×10 -4 mol / L Cu nanoparticle sol.

[0032] Preparation of CCu: Weigh 0.1426g of sucrose and dissolve it in 39.5mL of absolute ethanol to prepare an alcohol solution of sucrose, add 0.5mL of the above sol to the alcohol solution of sucrose to obtain a mixed solution, and then transfer the mixed solution into 50mL of polyamide In a reaction kettle lined with tetrafluoroethylene, after the lid was tightened, the reaction was carried out at 200 °C for 5 h to prepare a solution containing CCu. The solut...

Embodiment 2

[0036] Preparation of Hollow Structure Sr Coated Metal Nanoparticles 0.95 Al 2 O 4 :Tb 0.05 Au 1×10 -2

[0037] Preparation of Au nanoparticle sol: Weigh 41.2 mg of chloroauric acid (AuCl 3 ·HCl·4H 2 O) Dissolve into 10 mL of deionized water; when the chloroauric acid is completely dissolved, weigh 14 mg of sodium citrate and 6 mg of cetyltrimethylammonium bromide, and dissolve them into an aqueous solution of chloroauric acid under magnetic stirring 3.8 mg of sodium borohydride and 17.6 mg of ascorbic acid were weighed and dissolved in 10 mL of deionized water to obtain 10 mL with a concentration of 1×10 -2 mol / L sodium borohydride aqueous solution and 10mL concentration of 1×10 -2 mol / L ascorbic acid aqueous solution; under the environment of magnetic stirring, first add 5 mL sodium borohydride aqueous solution to the chloroauric acid aqueous solution, stir for 5 min, and then add 5 mL 1 × 10 chloroauric acid aqueous solution to the aqueous solution. -2 mol / L of asco...

Embodiment 3

[0042] Preparation of Hollow Structure Sr Coated Metal Nanoparticles 0.98 Al 2 O 4 :Tb 0.02 Ag 2.5×10 -4:

[0043] Preparation of Ag nanoparticle sol: Weigh 3.4 mg of silver nitrate (AgNO 3 ) was dissolved in 18.4 mL of deionized water; when the silver nitrate was completely dissolved, 42 mg of sodium citrate was weighed and dissolved in an aqueous silver nitrate solution under magnetic stirring; 5.7 mg of sodium borohydride was weighed and dissolved in 10 mL of deionized water, Get 10mL with a concentration of 1.5×10 -2 mol / L sodium borohydride aqueous solution; under the environment of magnetic stirring, add 1.6mL 1.5×10 to the silver nitrate aqueous solution at one time -2 mol / L sodium borohydride aqueous solution, then continue to react for 10min, that is, 20mL Ag content is 1 × 10 -3 mol / L of Ag nanoparticle sol.

[0044] Preparation of CAg: Weigh 3.003g of glucose and dissolve it in 35mL of absolute ethanol to prepare an alcohol solution of glucose, add 5mL of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com