A kind of polyester weight reduction dyeing auxiliary agent and its preparation method and application

A technology of dyeing auxiliaries and polyester, applied in the field of printing and dyeing, can solve the problems of high dyeing and finishing process, high pollution, etc., and achieve the effect of saving energy, reducing emissions, and reducing strength damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

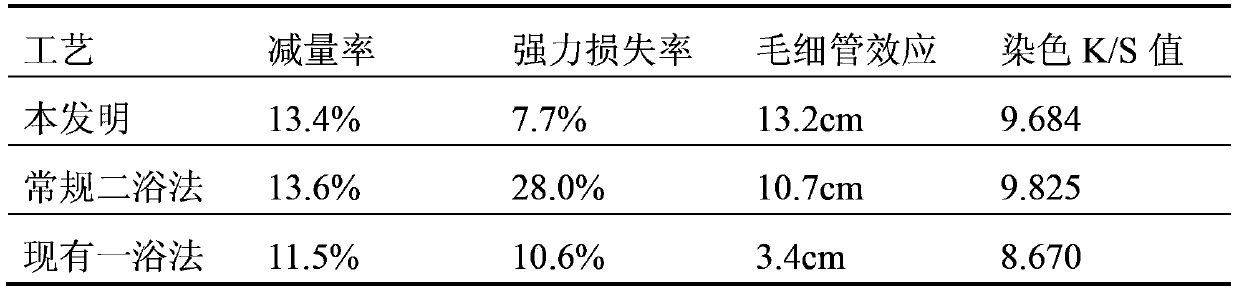

Embodiment 1 and comparative Embodiment 1

[0027] The raw material formula of polyester weight loss dyeing auxiliaries: ethylene glycol monobutyl ether 12%, 1,4-butyrolactone 12%, AEO-9 (fatty alcohol polyoxyethylene ether) 15%, SAS-60 (secondary alkyl Sodium sulfonate) 15%, water 46%.

[0028] Preparation method: add 46Kg of water to the reaction kettle, start stirring, then add 15Kg AEO-9, stir at room temperature for 20min, then heat up to 45°C, add 12Kg of ethylene glycol monobutyl ether, stir at constant temperature for 30min, then add 1,4- Butyrolactone 12Kg, stirred at constant temperature for 45min, finally added SAS-6015Kg, stirred at constant temperature for 20min, and adjusted pH to 6.5 with acetic acid and sodium hydroxide after cooling.

[0029] Application method: feed the cloth → add polyester dyeing auxiliaries (2% o.w.f., that is, the amount of the auxiliaries is 2% of the quality of the cloth), run for 20 minutes → feed acetic acid (0.1g / L), dyes (3% o.w.f., that is, dyes The dosage is 3% of the qual...

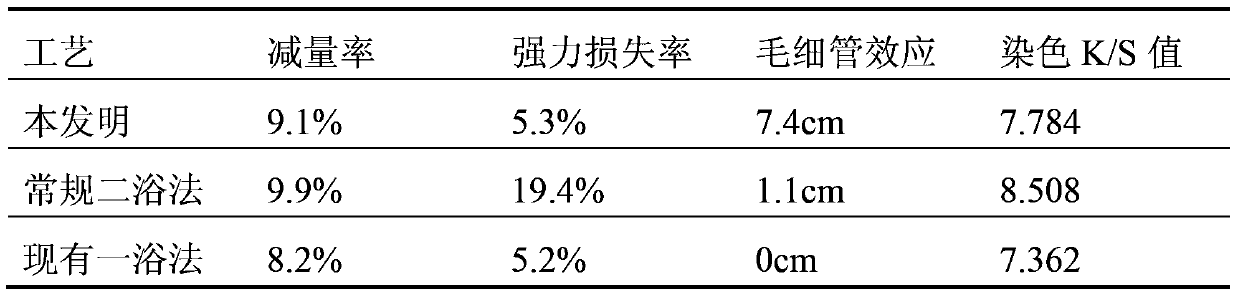

Embodiment 2 and comparative Embodiment 2

[0036] The raw material formula of polyester weight loss dyeing auxiliaries: ethylene glycol monobutyl ether 10%, 1,4-butyrolactone 15%, AEO-9 (fatty alcohol polyoxyethylene ether) 10%, SAS-60 (secondary alkyl Sodium sulfonate) 20%, water 45%.

[0037] Preparation method: add 45Kg of water to the reaction kettle, start stirring, then add AEO-910Kg, stir at room temperature for 30min, then heat up to 45°C, add 10Kg of ethylene glycol monobutyl ether, stir at constant temperature for 45min, and then add 1,4-butane Lactone 15Kg, stirred at constant temperature for 45min, finally added SAS-6020Kg, stirred at constant temperature for 15min, and adjusted pH to 6.0 with acetic acid and sodium hydroxide after cooling.

[0038] Application method: feeding cloth → adding polyester dyeing auxiliaries (1% o.w.f., that is, the amount of auxiliaries is 1% of the cloth quality), running for 20 minutes → feeding acetic acid (0.1g / L), dyes (3% o.w.f.) → heating up To 80 ℃, run for 20 minutes ...

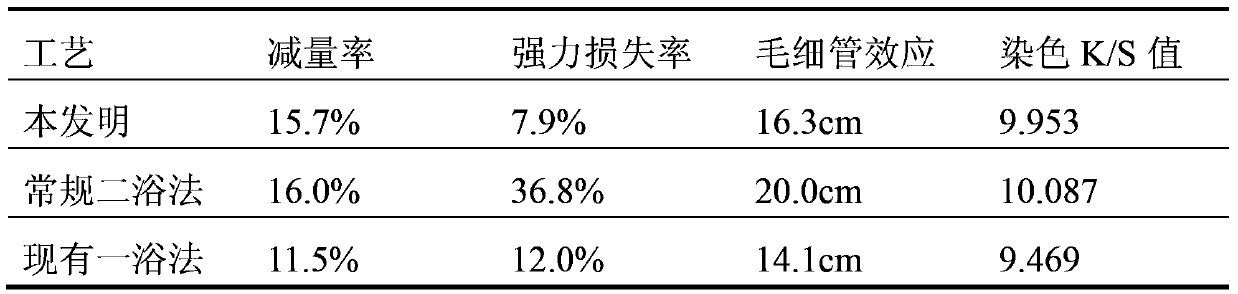

Embodiment 3 and comparative Embodiment 3

[0045] The raw material formula of polyester weight loss dyeing auxiliaries: ethylene glycol monobutyl ether 15%, 1,4-butyrolactone 10%, AEO-9 (fatty alcohol polyoxyethylene ether) 20%, SAS-60 (secondary alkyl group) Sodium sulfonate) 10%, water 45%.

[0046] Preparation method: add 45Kg of water to the reaction kettle, start stirring, then add AEO-920Kg, stir at room temperature for 15min, then heat up to 60°C, add 15Kg of ethylene glycol monobutyl ether, stir at constant temperature for 30min, and then add 1,4-butane Lactone 10Kg, stirred at constant temperature for 60min, finally added SAS-6010Kg, stirred at constant temperature for 30min, and adjusted pH to 5.5 with acetic acid and sodium hydroxide after cooling.

[0047] Application method: feeding cloth → adding polyester dyeing auxiliaries (3% o.w.f., that is, the amount of auxiliaries is 3% of the cloth quality), running for 20 minutes → feeding acetic acid (0.1g / L), dyes (3% o.w.f.) → heating up To 80 ℃, run for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com