P type FeNbTiSb thermoelectric material with high optimal value and preparation method thereof

A technology of thermoelectric materials and raw materials, applied in the direction of thermoelectric device lead-out wire materials, thermoelectric device manufacturing/processing, etc., can solve the problems of few researches on thermoelectric materials, and achieve abundant reserves, high production efficiency and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials were stoichiometrically compared to FeNb 0.8 Ti 0.2 After Sb is calculated and weighed, it is placed in a copper tube protected by Ar gas, and the high-frequency melting method is used to repeatedly smelt the ingot for 3 times to obtain an ingot, and then the ingot is crushed by a mechanical ball milling method to obtain submicron particles, followed by spark plasma sintering Methods The final samples were obtained by sintering at 850°C and 65MPa for 10 minutes.

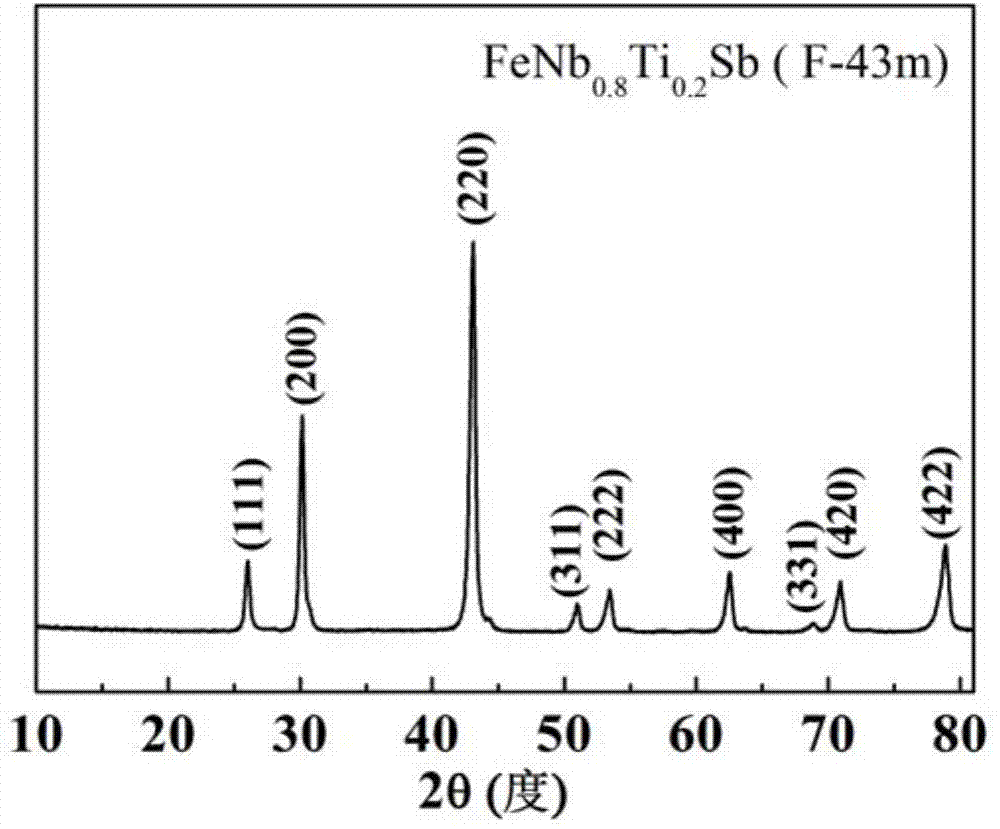

[0031] Adopt RigakuD / MAX-2550PC type X-ray polycrystal diffractometer (XRD) to carry out phase analysis to the sample that present embodiment makes, as figure 1 Shown, and confirmed as the FeNbSb-based structure, that is, the cubic structure (F43m), the space group number is 216.

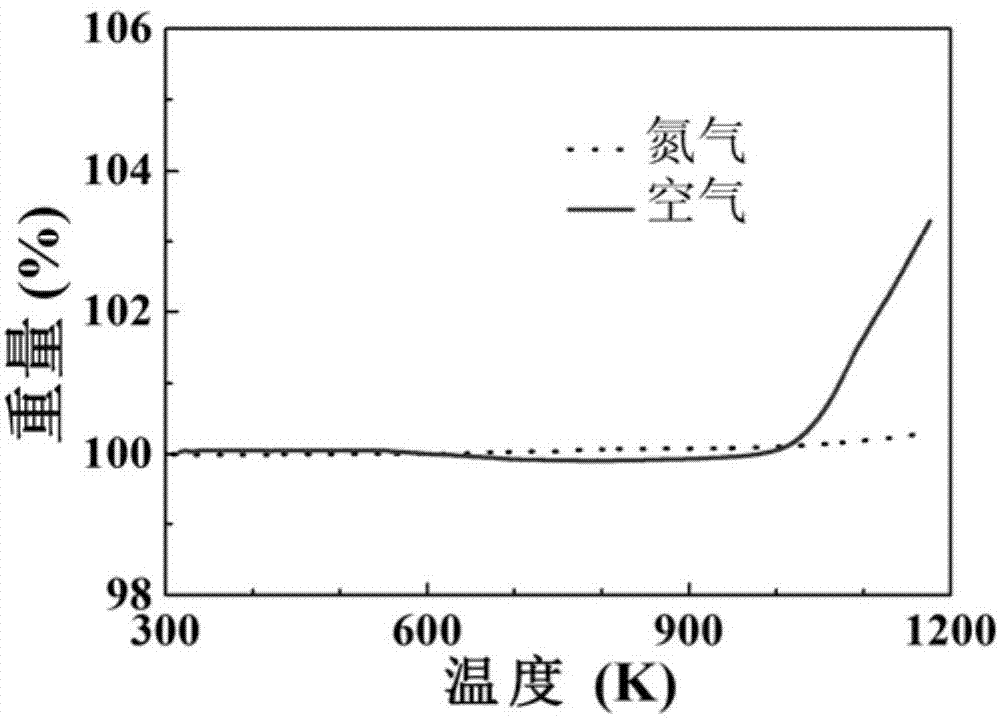

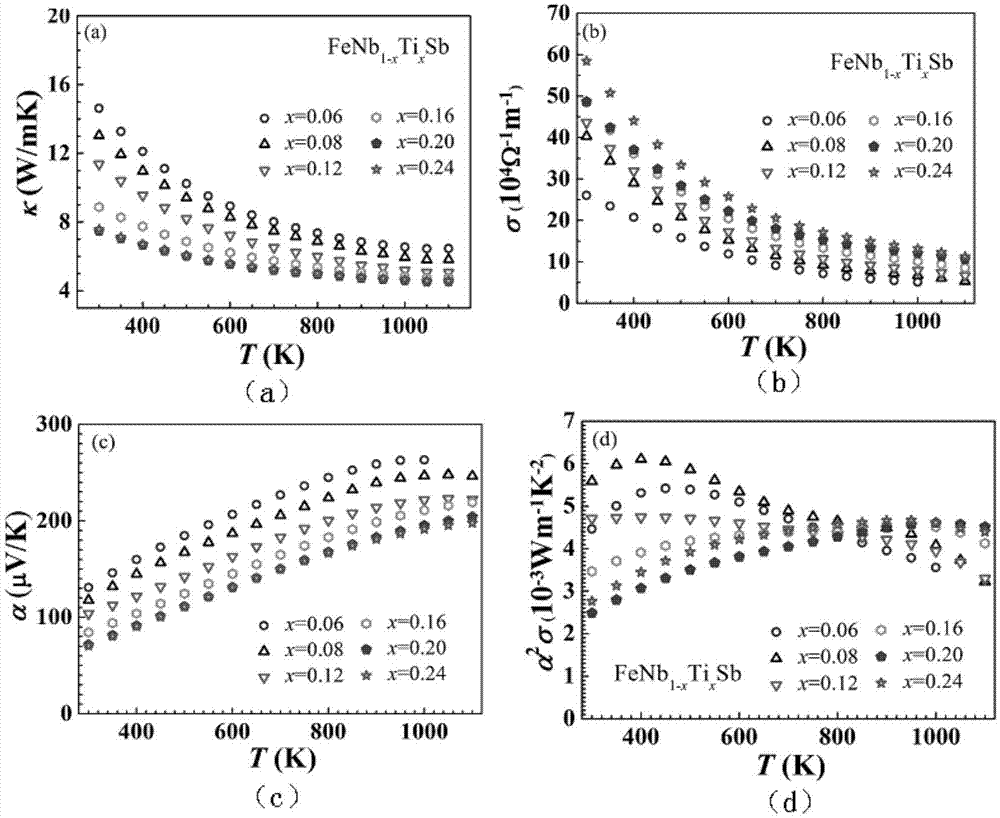

[0032] According to the thermal diffusivity measured by Netzsch LFA-457 laser pulse thermal analyzer, the specific heat measured by Netzsch DSC-404 differential specific heat meter and the density of the material, th...

Embodiment 2

[0037] Raw materials were stoichiometrically compared to FeNb 0.76 Ti 0.24 After Sb is calculated and weighed, it is placed in a copper tube protected by Ar gas, and the high-frequency melting method is used to repeatedly smelt the ingot for 3 times to obtain an ingot, and then the ingot is crushed by a mechanical ball milling method to obtain submicron particles, followed by spark plasma sintering Methods The final samples were obtained by sintering at 850°C and 65MPa for 10 minutes.

[0038] The thermal conductivity of the sample prepared in this embodiment is κ=4.6W·m at 1100K -1 K -1 .

[0039] The thermoelectric potential coefficient of the material at 1100K was measured by Linses LSR-3 equipment α=198μV / K, and the conductivity σ=11.3×10 4 S / m.

[0040] According to the above measured value according to zT=(α 2 σT / κ), the zT value of the sample prepared in this embodiment is about 1.06 at 1100K.

Embodiment 3

[0042] Raw materials were stoichiometrically compared to FeNb 0.84 Ti 0.16 After Sb is calculated and weighed, it is placed in a copper tube protected by Ar gas, and the high-frequency melting method is used to repeatedly smelt the ingot for 3 times to obtain an ingot, and then the ingot is crushed by a mechanical ball milling method to obtain submicron particles, followed by spark plasma sintering Methods The final samples were obtained by sintering at 850°C and 65MPa for 10 minutes.

[0043] The thermal conductivity of the sample prepared in this embodiment is κ=4.8W·m at 1100K -1 K -1 .

[0044] The thermoelectric potential coefficient of the material at 1100K was measured by Linses LSR-3 equipment α=219μV / K, and the conductivity σ=8.6×10 4 S / m.

[0045] According to the above measured value according to zT=(α 2σT / κ), the zT value of the sample prepared in this embodiment is about 0.96 at 1100K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com