Automatic production device of environmental protection antibiotic-free fermented?feed

A technology for fermented feed and production equipment, which is applied in the field of automatic production equipment for environmental protection and non-anti-fermented feed, can solve the problems of low production control accuracy, numerous and complicated procedures, unstable feed production quality, etc., and achieves shortening production time and simplifying operations. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

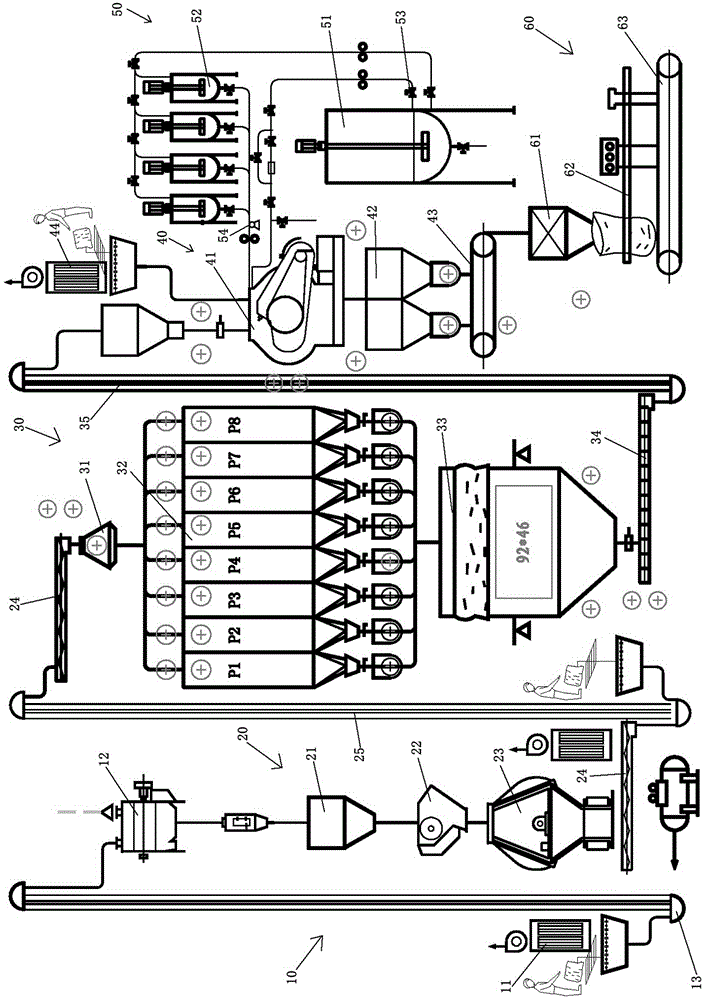

[0020] Such as figure 1 As shown, the present invention discloses an automatic production equipment for environmentally friendly non-antibiotic fermented feed, including a cleaning system 10 , a crushing system 20 , a batching system 30 , a bacterial solution filling system 40 , a mixing system 50 and a packaging system 60 . The outlet of the cleaning system 10 is connected to the inlet of the crushing system 20, the outlet of the crushing system 20 is connected to the inlet of the batching system 30, the outlet of the batching system 30 is connected to the inlet of the mixing system 50 for solid materials, and the bacterial liquid filling system 40 The discharge port is connected to the bacteria liquid feed port of the mixing system 50 , and the discharge port of the mixing system 50 is connected to the packaging system 60 .

[0021] The cleaning system 10 is composed of a pulse dust collector 11 and a permanent magnet cylinder 12 . The pulse dust collector 11 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com