Binder-free biological organic-inorganic complete element composite microbial fertilizer, preparation method and application thereof

A bio-organic-inorganic, composite microorganism technology, applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of inconvenient mechanized application, difficult market promotion, unfavorable transportation and storage, etc., to facilitate mechanized fertilization and protect health. , good effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Production of bio-organic fertilizer

[0037] Inoculate Bacillus amyloliquefaciens SQR9 with the preservation number of CGMCC NO.5808 into the PDA culture medium for liquid fermentation production. The conditions for fermentation production are: the culture temperature range is 30-37 °C, and the stirring speed is 170-180 °C. revolutions per minute, spores are formed in the middle and late stages of fermentation, so that the amount of bacteria or spores in the fermentation broth is ≥ 1×10 9 pieces / ml.

[0038]Mix decomposed cow dung compost and rapeseed meal evenly according to the weight ratio of 6:4, inoculate SQR-9 fermentation broth into the mixture of rapeseed meal and decomposed cow dung compost for solid fermentation, add SQR9 fermentation broth 40~ 60L, turn the pile 1-2 times a day during the solid fermentation process, so that the solid fermentation temperature does not exceed 60°C, the fermentation ends after 6-7 days, and the SQR9 content reaches 1×10 8 ...

Embodiment 2

[0044] Example 2 Granulation test

[0045] 1 Effect of raw material powder fineness on granulation

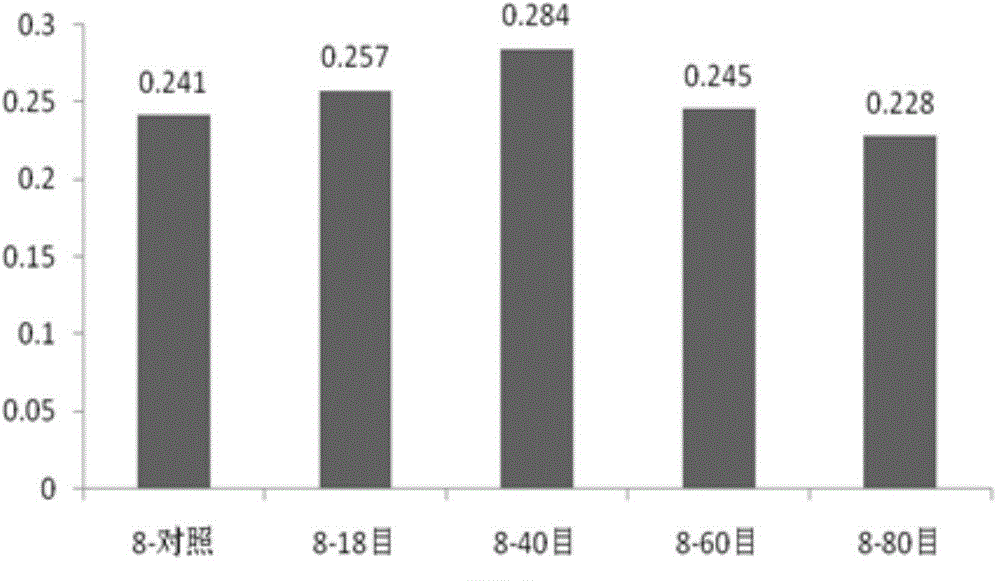

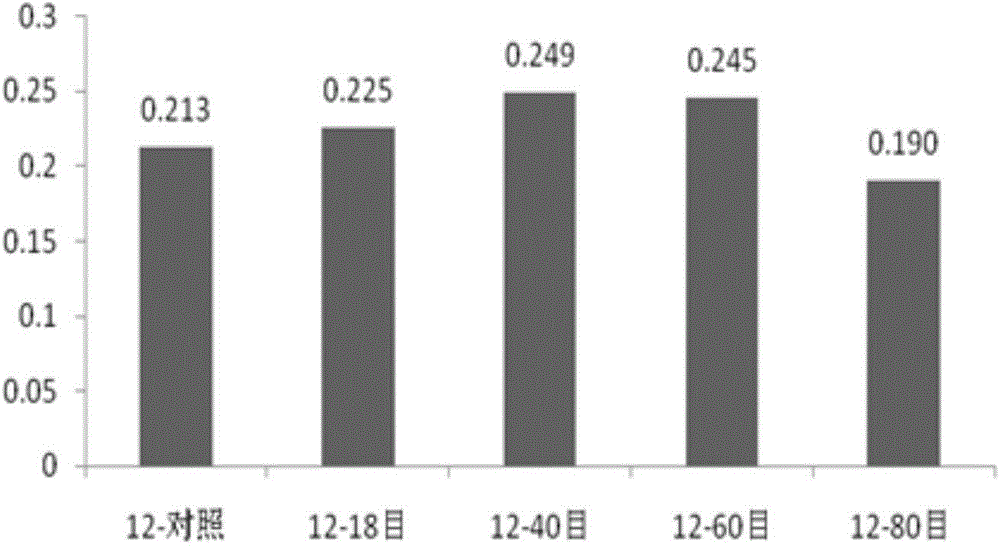

[0046] Two " whole element " compound microbial fertilizer formulas (with formula 1 and formula 2 in embodiment 1) respectively set up four and handle a contrast, the bio-organic fertilizer after the air-drying is pulverized with hammer mill, respectively successively Use 80-mesh sieve, 60-mesh sieve, 40-mesh sieve, and 18-mesh sieve to sieve the raw materials with 80-mesh, 60-mesh, 40-mesh, and 18-mesh bio-organic fertilizer raw materials for four fineness treatments, and only use 18-mesh sieve The obtained mixed raw material was used as a control. Use formula 1 (total nutrient is 8% and only add ammonium sulfate) and formula 2 (total nutrient is 12% to add 3.82%N, 1%P respectively) 2 o 5 and 2%K 2 O) Granulation.

[0047] 1.1 Effect of raw material fineness on water content during granulation

[0048] Such as Figure 1 ~ Figure 2 It can be seen that under different raw...

Embodiment 3

[0079] Embodiment 3 field test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com