High-formability high-weatherability ultrathin hot-rolled steel plate and CSP (compact strip production) technology thereof

A hot-rolled steel plate and production process technology, applied in the field of metallurgy, can solve the problems of restricting development and promotion, secondary forming cracking, easy deformation of the billet shell, etc., and achieves a reduction in the leakage rate of continuous casting, satisfactory weather resistance, and steel surface quality. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0038] Table 1 lists the chemical components and weight percentages of the Ti+Mo microalloyed high-formation high-weathering ultra-thin steel sheets in Examples 1-7 of the present invention, and the balance is Fe and unavoidable impurities.

[0039] Table 1

[0040]

[0041]

[0042] In Examples 1-7, the CSP process is used to produce the above-mentioned high-formation and high-weather-resistance ultra-thin steel plates, and the steps are as follows:

[0043] 1) Carry out converter smelting, tap P≤0.012% after smelting, preferably 0.01%;

[0044] 2) After smelting, the molten steel is refined outside the furnace, and then cast into a billet in a CSP continuous casting machine. During the continuous casting process, the basicity of the mold slag is controlled at 1.0-1.15, the viscosity is controlled at 1.42-1.65 poise.seconds, and the melting point is controlled at 1030-1100 ℃, to ensure that the crystallizer heat flow is controlled at 2.45-2.55mw / m 2 , while controllin...

Embodiment 3

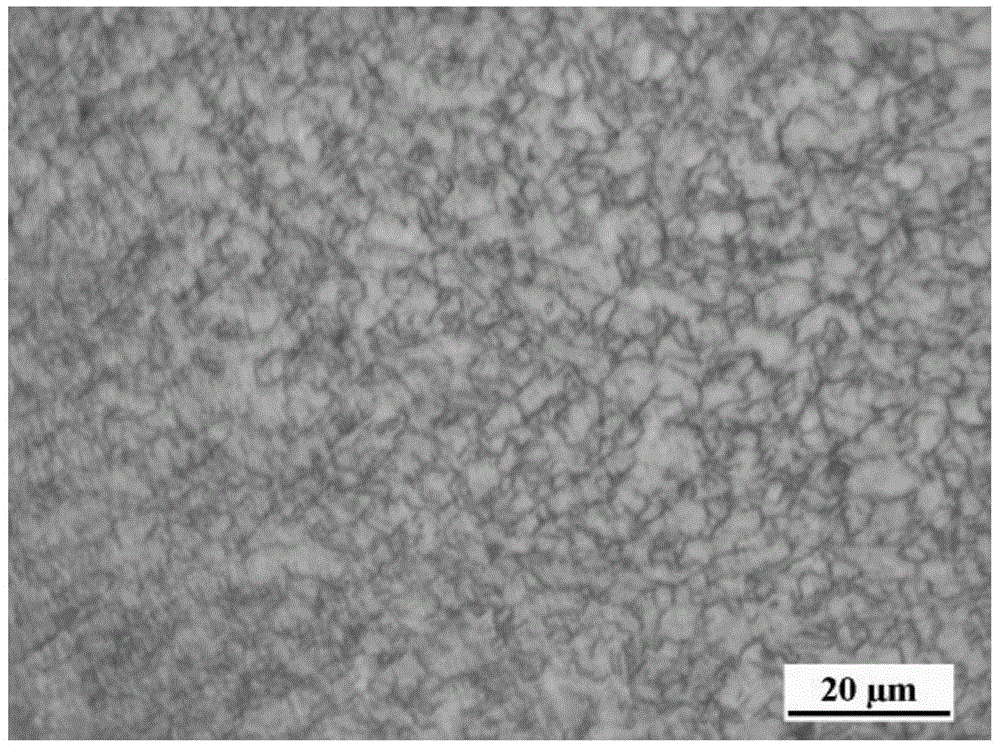

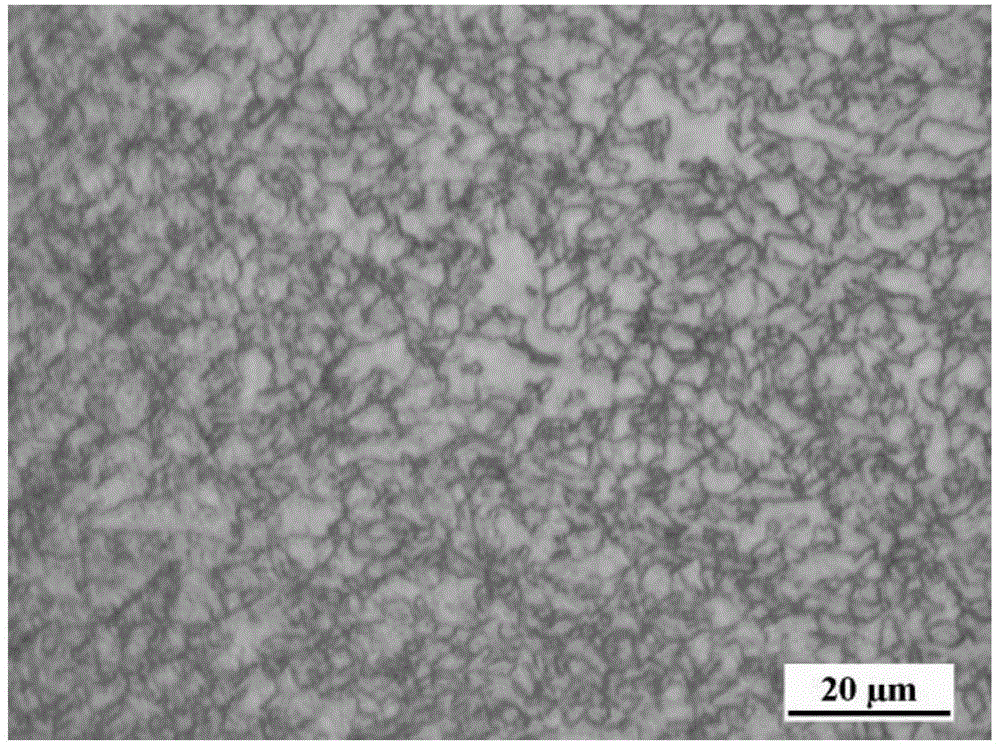

[0062] For the metallographic structure of the high-formation, high-weathering, ultra-thin steel plate produced in Example 3, see figure 1 , the obtained structure is mainly acicular ferrite structure, the grains are relatively uniform, and the acicular ferrite has a strong deformation coordination ability, which is beneficial to improve the formability of the steel plate and avoid cracking; the steel plate produced in the comparison The metallographic structure of see figure 2 , its metallographic structure is mainly polygonal ferrite, and there are some coarse ferrite grains.

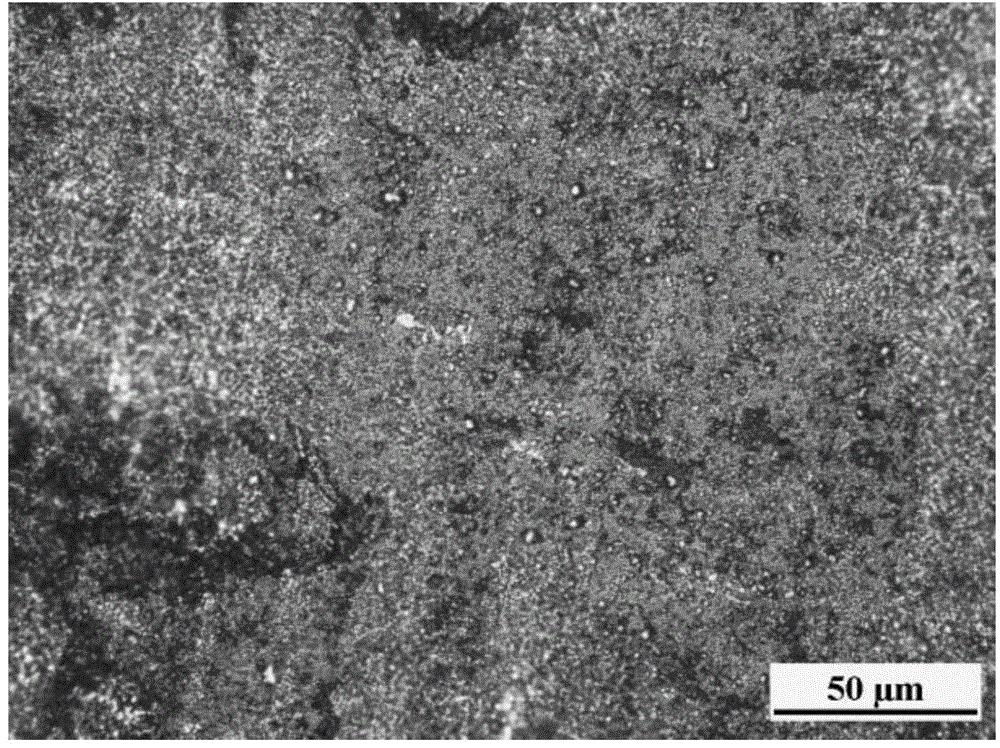

[0063] The surface morphology of embodiment 3 steel plate sees image 3 , the surface quality is excellent, and no microcracks are observed on the steel surface; the surface morphology of the comparative steel plate is shown in Figure 4 , micro-cracks up to 100 μm were observed on the surface, and the directions of the cracks were randomly distributed. Once the surface micro-cracks were generated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com