Soft-magnetic composite film and manufacturing method and application of soft-magnetic composite film in electronic equipment

A soft magnetic composite and electronic equipment technology, applied in the application of magnetic film to substrate, magnetic field/electric field shielding, circuit, etc., can solve the problem of low signal transmission quality of electronic equipment, poor near-field electromagnetic noise absorption effect of composite film, Magnetic permeability is not high enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

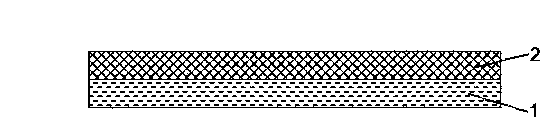

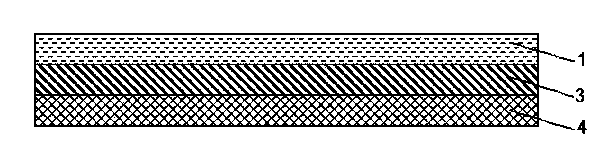

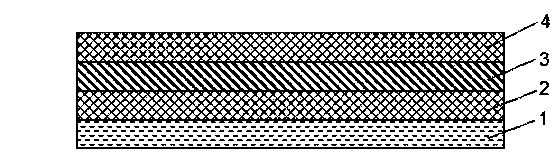

[0099] An iron-nickel soft magnetic composite film for absorbing near-field high-frequency electromagnetic noise, the iron-nickel soft magnetic composite film comprising:

[0100] a, flaky iron-nickel soft magnetic alloy powder, which contains 45%-60% iron and 40%-55% nickel by mass fraction; b, described flaky iron-nickel soft magnetic alloy powder is phased with an organic bonding material Mix and make it form iron-nickel soft magnetic composite film;

[0101] c. The thickness of the iron-nickel soft magnetic composite film ranges from 20 microns to 0.49 mm;

[0102] d. The average diameter of the flake iron-nickel soft magnetic alloy powder is 1 micron to 300 microns, the average thickness is 50 nanometers to 5 microns, and the average aspect ratio of the flake iron nickel soft magnetic alloy powder is greater than 16 and less than 2000;

[0103] e. Preferably, the volume fraction of the flake iron-nickel soft magnetic alloy powder accounts for 31% to 73% of the volume of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com