Microextraction probe electrospray ion source and manufacturing method and application of microextraction probe electrospray ion source

An extraction and probe technology, applied in the chemical field, can solve the problems of unstable signal, short duration, and inability of spray solvent to infiltrate fibers effectively, and achieve the effect of strong selectivity and enrichment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

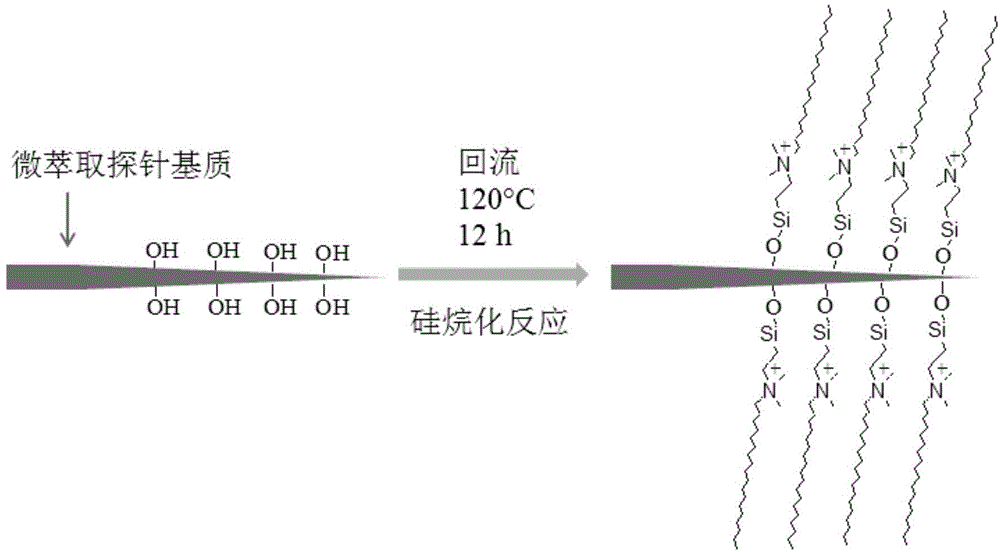

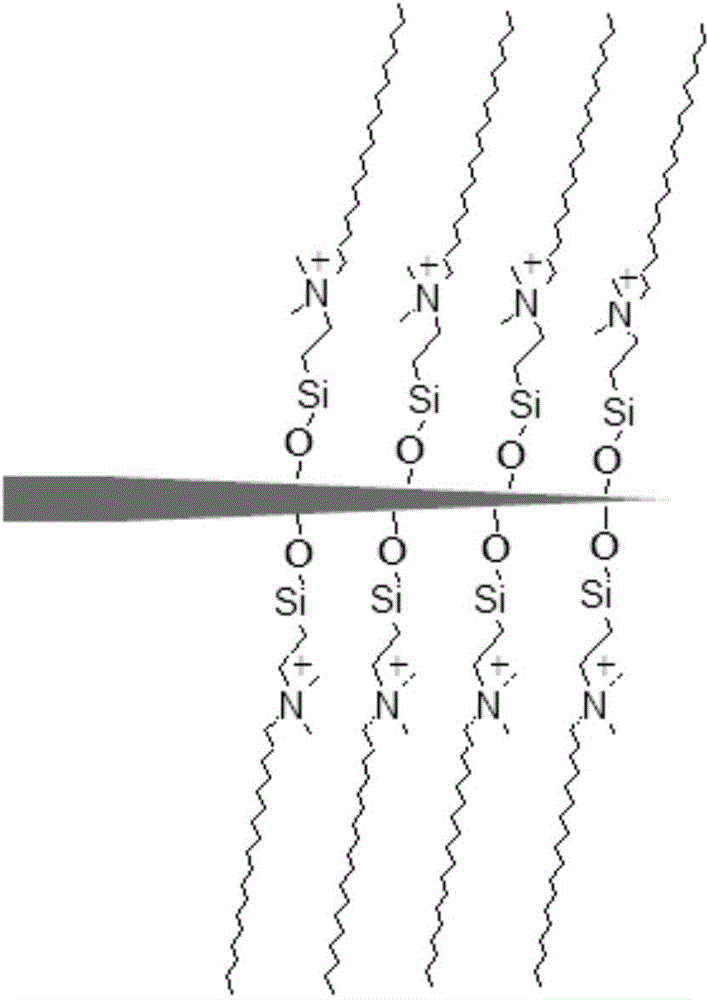

[0052] The preparation of embodiment 1 microextraction probe

[0053] First cut the wood fiber into a length of about 2 cm, and then use a knife to further cut the tip of the wood fiber into a thinner tip (0.1-0.2 mm in outer diameter, which is similar to the capillary size of a commercial electrospray ion source). Wood fiber matrices for microextraction probes. Then, the wood fiber matrix was placed in a two-necked flask, and 100 mL of anhydrous N,N-dimethylformamide and 5 mL of dimethyloctadecyl[3-(trimethoxysilyl)propyl]chloride were added Ammonium, nitrogen, heated to 120 ° C, stirred and refluxed for 12 hours. After the reaction was completed, the wood fiber matrix with the adsorption material bonded on the surface was repeatedly washed with methanol three times, and dried naturally to obtain the micro-extraction probe.

Embodiment 2

[0054] The characterization of the microextraction probe of embodiment 2

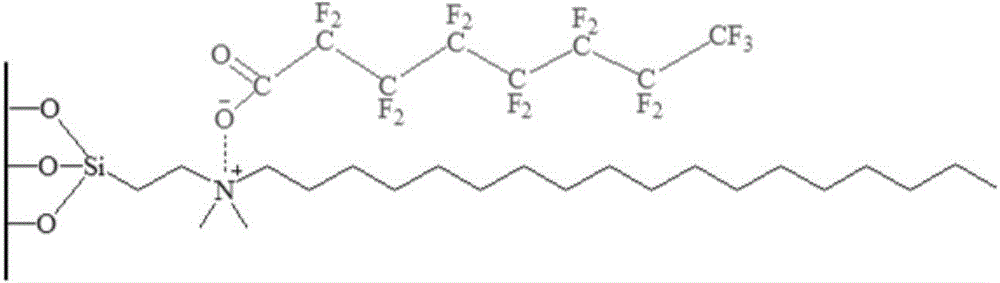

[0055] Figure 5 The photoelectron spectroscopy of the microextraction probe surface is shown, from which C-, O-, N- and Si-related peaks can be observed. The content percentage of Si and N in the surface-bonded wood fiber matrix is 2.14%-2.35%. The Si2p peak shows Si-CH at a binding energy of 102.8eV 2 bond and the Si-O bond at 102.2eV ( Figure 5-2 ), the N1s peak shows the N-CH with binding energy at 399.6eV 2 key and N-CH of 402.2 3 key( Figure 5-3 ). Through photoelectron spectroscopy analysis, it was confirmed that the silyl group of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride was bonded to the hydroxyl group on the surface of the wood fiber matrix through a silanization reaction.

[0056] Figure 6 Shown are the scanning electron micrographs of the unmodified wood fiber matrix and the microextraction probe of the present invention. It can be clearly shown in the fi...

Embodiment 3

[0057] Example 3 Extraction and Microextraction Probe Electrospray Mass Spectrometry Analysis

[0058] The operation mode of sample extraction is consistent with that of solid-phase microextraction, and the mode of direct extraction is adopted. Before extraction, the microextraction probe was rinsed with methanol for 30 s. After the extraction, the micro-extraction probe was quickly taken out from the sample, then rinsed in pure water for 10 seconds and then taken out, and then the micro-extraction probe was analyzed by electrospray mass spectrometry after natural drying.

[0059] The extracted micro-extraction probe was fixed on the three-dimensional mobile stage, so that the tip of the micro-extraction probe was aligned with the entrance of the mass spectrometer and was 10 mm away from the entrance of the mass spectrometer. An external –3.5kV high-voltage electric field is loaded on the micro-extraction probe, and then 5 μL of methanol spray solvent is added dropwise on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com