Solid phase micro-extraction device and method for preparing fibre extraction head thereof

A technology of extraction device and extraction head, which is applied in the direction of ion exchange treatment device, ion exchange regeneration, ion exchange, etc., to achieve the effects of simple structure, easy production and high enrichment multiple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

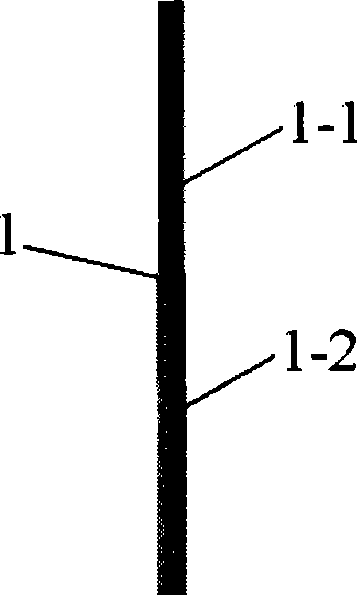

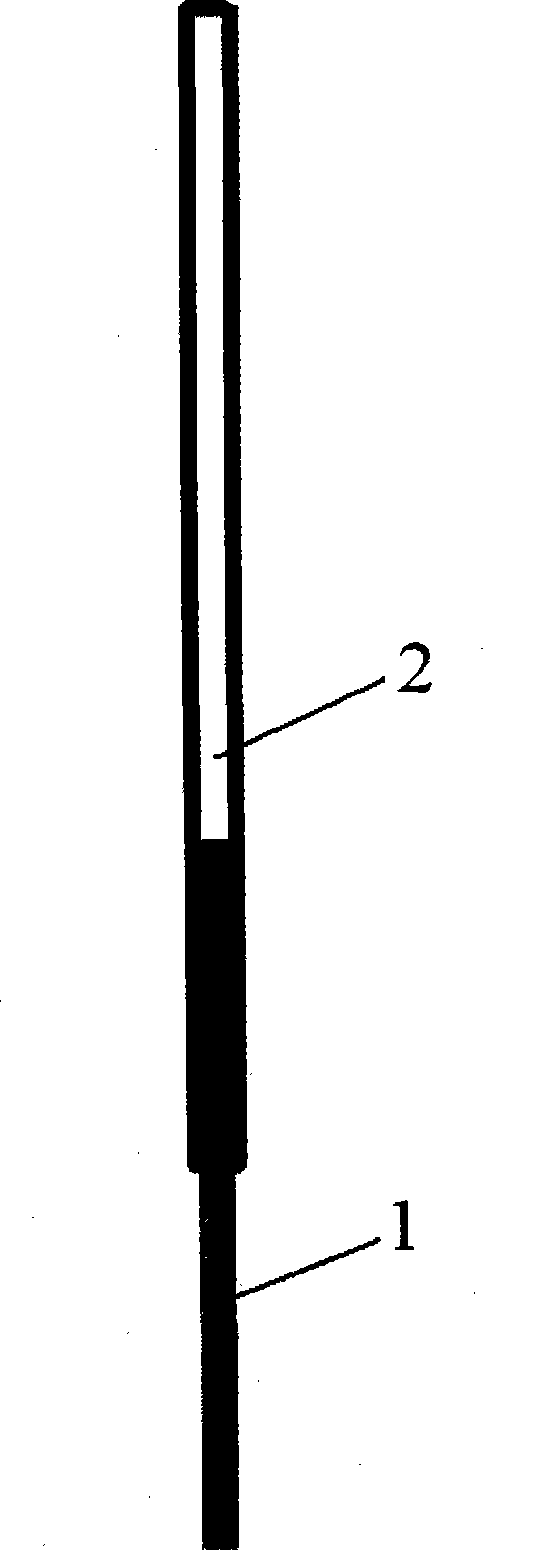

[0027] Example 1. Preparation of fiber extraction head with metal organic porous framework material MOF-199 on the surface

[0028] First, the pretreatment of metal fibers:

[0029] Put a 1.5-4.0cm long part of a metal fiber with an outer diameter of 0.05-0.3mm and a total length of 3.0-8.0cm in aqua regia, and corrode it at room temperature for 20-60 minutes, and control the outer diameter of the metal fiber to 0.05-8.0cm by controlling the corrosion time. 0.20mm, put the other end of the metal fiber (about 1.5-44.0cm) in HF, corrode at room temperature for 20-40 minutes until the surface of this metal fiber turns black, rinse with pure water and dry.

[0030] Second, in situ preparation of metal-organic porous framework materials on the surface of metal fibers:

[0031] 0.437g Cu 2 (NO 3 ) 2 3H 2 O was dissolved in 6mL of pure water, 0.640g of trimesic acid was dissolved in 18mL of absolute ethanol, ultrasonically dissolved for 10min and then mixed, the mixed solution ...

Embodiment 2

[0032] Example 2, the preparation of the fiber extraction head whose surface is the metal organic porous framework material MOF-5

[0033] First, the pretreatment of metal fibers:

[0034] Put a 1.5-4.0cm long part of a metal fiber with an outer diameter of 0.05-0.3mm and a total length of 3.0-8.0cm in aqua regia, and corrode it at room temperature for 20-60 minutes, and control the outer diameter of the metal fiber to 0.05-8.0cm by controlling the corrosion time. 0.20mm, put the other end of the metal fiber (about 1.5-4.0cm) in HF, corrode at room temperature for 20-40 minutes until the surface of this metal fiber turns black, rinse with pure water and dry.

[0035] Second, in situ preparation of metal-organic porous framework materials on the surface of metal fibers:

[0036] 0.580g Zn(NO 3 ) 2 6H 2 O, 0.160g terephthalic acid, dissolved in 20mL N, N-dimethylformamide, ultrasonically dissolved for 10min, put the solution in a 35mL polytetrafluoroethylene reactor, put th...

Embodiment 3

[0037] Example 3, the surface is the preparation of the fiber extraction head of metal organic porous framework material Zn (BDC) (dabco)

[0038]First, the pretreatment of metal fibers:

[0039] Put the 1.54.0cm long part of a metal fiber with an outer diameter of 0.05-0.3mm and a total length of 3.0-8.0cm in aqua regia, and corrode it at room temperature for 20-60 minutes, and control the outer diameter of the metal fiber to 0.05-0.20 by controlling the corrosion time. mm, put the other end of the metal fiber (about 1.5-4.0cm) in HF, corrode at room temperature for 20-40 minutes until the surface of this metal fiber turns black, rinse with pure water and dry.

[0040] Second, in situ preparation of metal-organic porous framework materials on the surface of metal fibers:

[0041] 0.50g Zn(NO 3 ) 2 6H 2 O, 0.280g terephthalic acid, 0.094g triethylenediamine were dissolved in 20mL N,N-dimethylformamide, and after ultrasonic dissolution for 10min, the solution was placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com