A kind of method for fixing pollutant organophosphate in co-pyrolysis process

An organic phosphate and pollutant technology, applied in the field of co-pyrolysis of solid waste, can solve environmental and human health hazards and other problems, and achieve the effect of reducing risks, not easy to pollute phosphorus, and simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

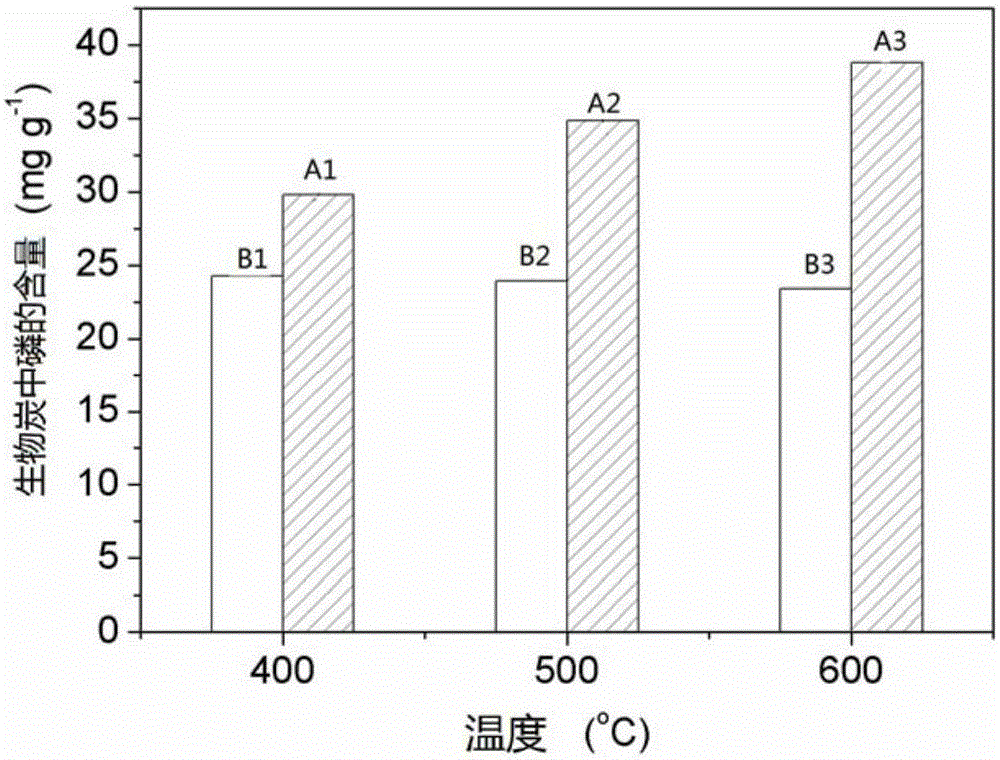

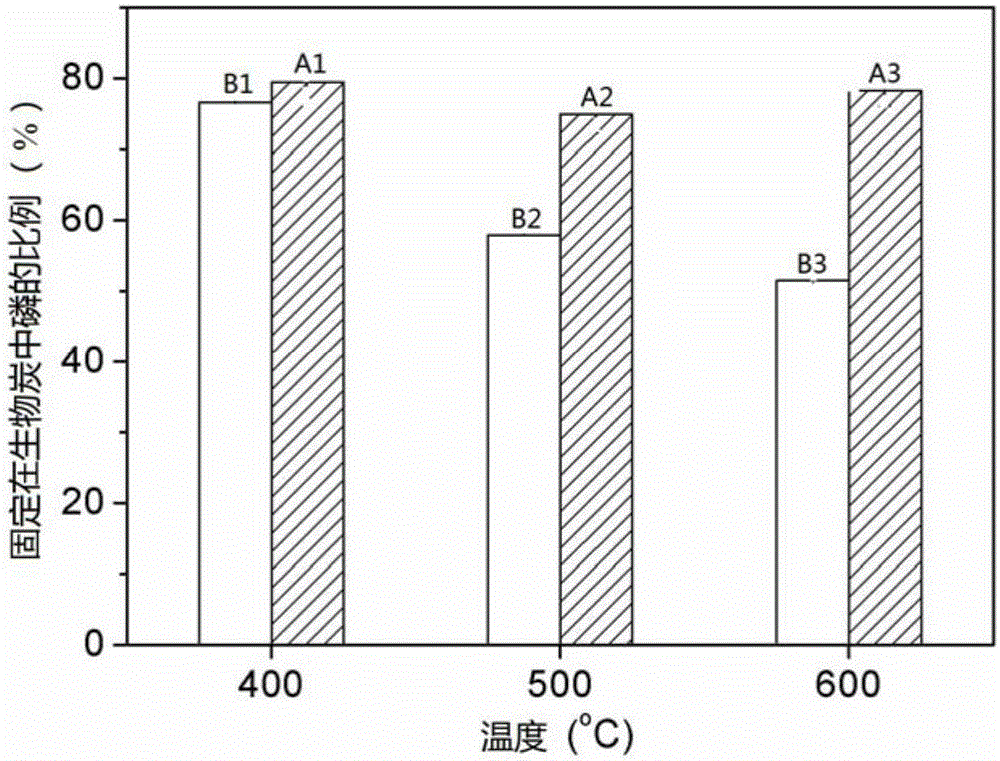

[0030] In order to facilitate the analysis and research of later products, this embodiment directly uses lignin and tri(butoxyethyl) phosphate (TBEP) as feedstock, instead of organic phosphate in biomass and plastics, to exclude other factors. Influence, Accurate Study of the Fixation of Organophosphates on Pyrolyzed Biochar.

[0031] The specific process is as follows:

[0032] a, the preparation contains 34.3g / LCaCl 2 , 62.9g / LMgCl 2 ·6H 2 O ethanol solution;

[0033] b. Mix lignin and tri(butoxyethyl)phosphate (TBEP) according to the ratio of lignin mass: phosphorus element mass in TBEP=59:1 to obtain a mixture, pulverize the mixture, and pass through a 100-mesh sieve to obtain a sample A;

[0034] c. Spray the mixed solution evenly on the sample A obtained in step b, and then dry it at 80°C to obtain the feed; the mass ratio of the mixed solution to sample A is 4:5; the phosphorus content in the feed is measured (calculated as phosphorus element) is about 2wt%;

[0...

Embodiment 2

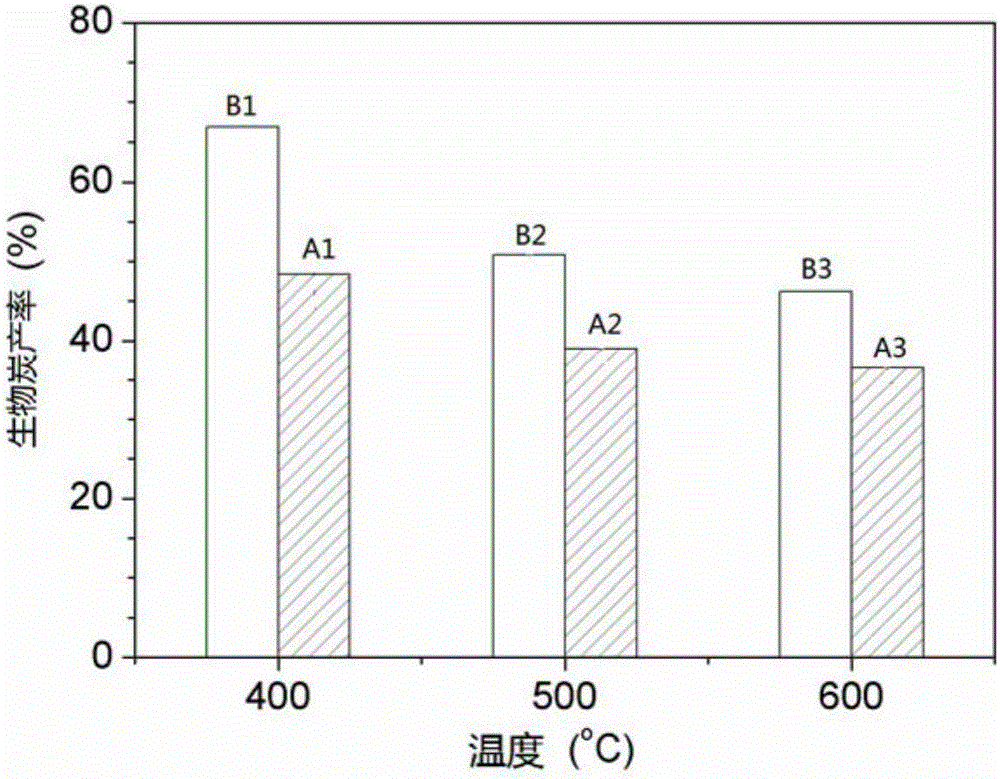

[0038] In this example, the same method as in Example 1 is used to explore the method of fixing pollutant organophosphates in the process of co-pyrolysis, the difference is that the pyrolysis temperature in step d is 500°C, and the obtained biochar is ground and passed through a 100-mesh sieve, and named It is biochar sample A2. Biochar yield was 50.9%

Embodiment 3

[0040] In this example, the same method as in Example 1 is used to explore the method of fixing pollutant organophosphates in the process of co-pyrolysis, the difference is that the pyrolysis temperature in step d is 600°C, and the obtained biochar is ground and passed through a 100-mesh sieve, and named It is biochar sample A3. Biochar yield was 46.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com