A kind of pp/pet blending environment-friendly waterproof and oil-proof automobile outer wheel cover and its manufacturing method

A car outer wheel cover, waterproof and oil-proof technology, applied in the direction of wheels, chemical instruments and methods, wheel cover plates, etc., can solve the problems of high cost, loud sand and stone beating noise, easy embrittlement, etc., and achieve low cost and simple processing , Excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

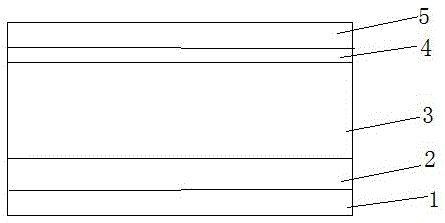

[0055] A PP / PET blended environmental protection waterproof and oil-proof automobile outer wheel cover, including a hot-melt felt layer 3, the back of the hot-melt felt layer 3 is provided with a waterproof and oil-proof layer 2, and the hot-melt felt layer 3 is made of two kinds of PP and PET The fiber layer formed by mixing materials, in terms of mass percentage, the hot-melt felt layer 3 includes 40% PP and 60% PET, the square gram weight of the waterproof and oil-proof layer 2 is 90g / ㎡, and the waterproof and oil-proof layer 2 Oil layer 2 comprises following weight components:

[0056] PE: 50 copies;

[0057] PA: 45 copies;

[0058] Coupling agent: vinyltrimethoxysilane: 0.5 parts;

[0059] Lubricant: a mixture of paraffin oil and paraffin wax with a weight component ratio of 1:2: 1.0 parts;

[0060] Stearic acid: 0.3 parts;

[0061] Flame retardant: a mixture of ammonium polyphosphate and pentaerythritol with a ratio of 1:2 by weight: 0.5 parts;

[0062] Antibacteria...

Embodiment 2

[0082]A PP / PET blended environmental protection waterproof and oil-proof automobile outer wheel cover, including a hot-melt felt layer 3, the back of the hot-melt felt layer 3 is provided with a waterproof and oil-proof layer 2, and the hot-melt felt layer 3 is made of two kinds of PP and PET The fiber layer formed by mixing materials, in terms of mass percentage, the hot-melt felt layer 3 includes 50% PP and 50% PET, the square gram weight of the waterproof and oil-proof layer 2 is 120g / ㎡, and the waterproof and oil-proof layer 2 Oil layer 2 comprises following weight components:

[0083] PE: 55 parts;

[0084] PA: 50 copies;

[0085] Coupling agent: vinyltrimethoxysilane: 0.8 parts;

[0086] Lubricant: a mixture of paraffin oil and paraffin wax with a weight component ratio of 1:2: 1.8 parts;

[0087] Stearic acid: 0.8 part;

[0088] Flame retardant: a mixture of ammonium polyphosphate and pentaerythritol with a ratio of 1:2 by weight: 1.0 parts;

[0089] Antibacterial ...

Embodiment 3

[0109] A PP / PET blended environmental protection waterproof and oil-proof automobile outer wheel cover, including a hot-melt felt layer 3, the back of the hot-melt felt layer 3 is provided with a waterproof and oil-proof layer 2, and the hot-melt felt layer 3 is made of two kinds of PP and PET The fiber layer formed by mixing materials, in terms of mass percentage, the hot-melt felt layer 3 includes 60% PP and 40% PET, the square gram weight of the waterproof and oil-proof layer 2 is 150g / ㎡, and the waterproof and oil-proof layer 2 Oil layer 2 comprises following weight components:

[0110] PE: 60 copies;

[0111] PA: 55 copies;

[0112] Coupling agent: vinyltrimethoxysilane: -1.0 part;

[0113] Lubricant: a mixture of paraffin oil and paraffin wax with a weight component ratio of 1:2: 2.5 parts;

[0114] Stearic acid: 1.0 parts;

[0115] Flame retardant: a mixture of ammonium polyphosphate and pentaerythritol with a ratio of 1:2 by weight: 1.5 parts;

[0116] Antibacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com