Preparation method of racemic theanine

A theanine and racemate technology, which is applied in the field of chemical method racemization of theanine, can solve the problems of difficulty in obtaining D-theanine standard samples, hindering the research work of theanine, and failing to prepare pure D-type products, etc. To achieve the effect of simple operation, elimination or reduction of D-type content, and reduction of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

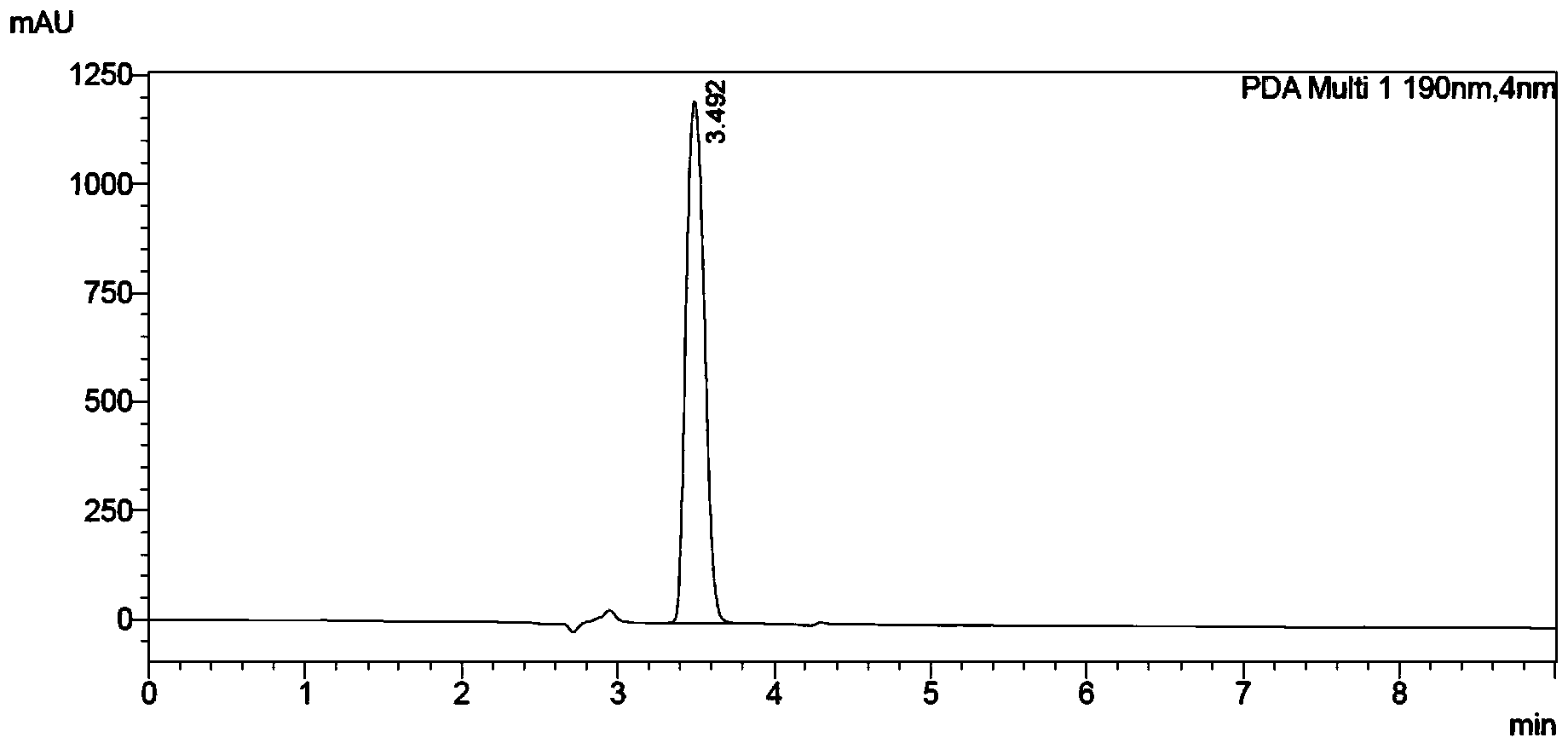

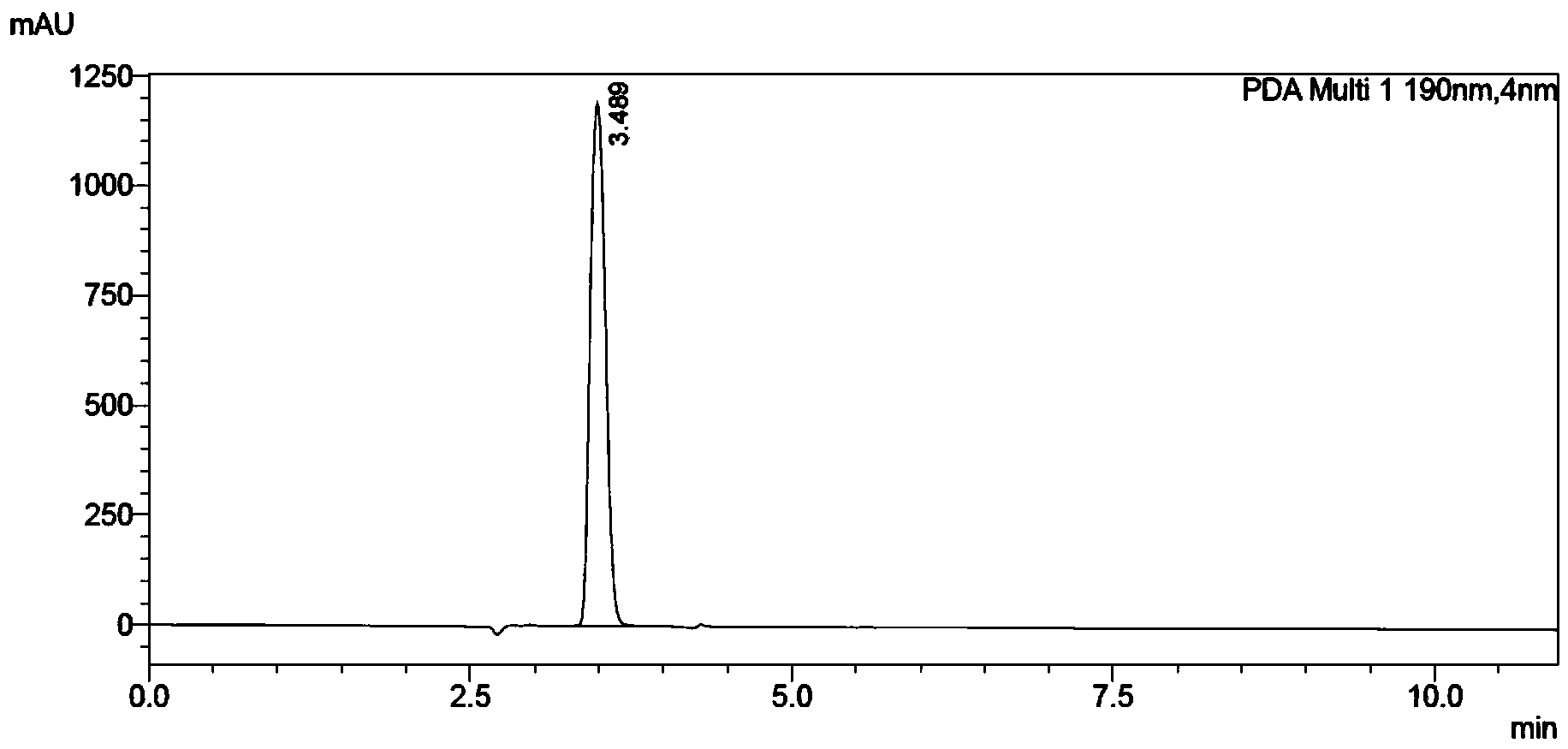

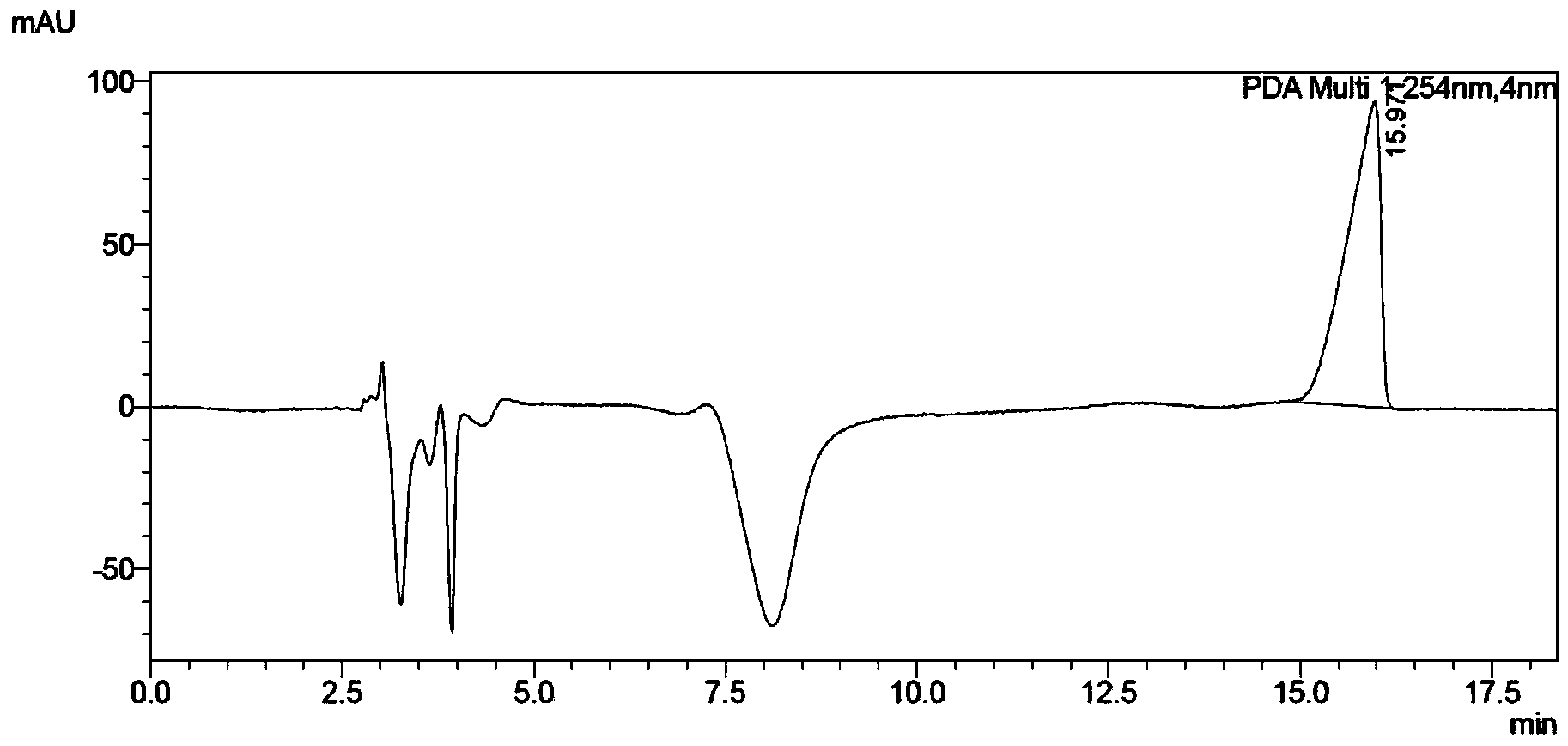

[0047] Embodiment 1: 10g theanine is dissolved in 200ml acetic acid, add 0.2ml salicylaldehyde. Heat in a water bath at 80°C, stir, take 5ml of the reaction solution every 10min and dilute 25ml to measure the optical rotation. After 70min, the measured optical rotation is 0. After drying by rotary evaporation, wash with ethanol and suction filter to generate racemic theanine.

Embodiment 2

[0048] Example 2: 10 g of theanine was dissolved in 200 ml of acetic acid, and 0.2 ml of salicylaldehyde was added. Heat and stir in a water bath at 85°C, take 5ml of the reaction solution every 10min and dilute 25ml to check the optical rotation. After 40 minutes, 5ml was diluted to 25ml and the optical rotation was measured as 0. After drying by rotary evaporation, it was washed with ethanol and suction filtered to generate racemic theanine.

Embodiment 3

[0049] Example 3: 10 g of theanine was dissolved in 200 ml of acetic acid, and 0.2 ml of salicylaldehyde was added. Heat and stir in a water bath at 90°C, take 5ml of the reaction solution every 10min and dilute 25ml to check the optical rotation. After 40 minutes, 5ml was diluted to 25ml and the optical rotation was measured as 0. After drying by rotary evaporation, it was washed with ethanol and suction filtered to generate racemic theanine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com