Water-soluble ionic type hydrophobic associated polymer oil-displacing agent and preparation method and application thereof

A hydrophobic association and ionic technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and shear dilution resistance, complicated operation, high cost, low cost and simple preparation method. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Preparation of cationic monomer 3-(allyloxy)-N,N,N-triethyl-2-hydroxypropane ammonium bromide (MOC)

[0062] The preparation method of MOC comprises the steps:

[0063] (1) After allyl glycidyl ether (a1) is diluted with the first organic solvent dichloromethane, the temperature is raised to reflux, and diethylamine (a2) is added dropwise to react; wherein, by the amount of substance, n (a1):n(a2)=1:1.1;

[0064] (2) After the dropwise addition was completed, the reaction was continued for 5 hours to obtain a crude product of 1-(allyloxy)-3-(diethylamino)propan-2-ol (a3);

[0065] (3) with reduced pressure distillation, remove the first organic solvent methylene chloride and excess diethylamine, obtain purer a3;

[0066] (4) After diluting a3 with the second organic solvent toluene, slowly drop bromoethane (a4) at 80°C; continue the reaction for 5 hours to obtain 3-(allyloxy)-N,N, N-triethyl-2-hydroxypropane-1-ammonium bromide (MOC) crude product; Wherein, by the ...

Embodiment 2

[0093] 1. Preparation of cationic monomer 3-(allyloxy)-N,N,N-triethyl-2-hydroxypropane ammonium bromide (MOC)

[0094] The preparation method of MOC comprises the steps:

[0095] (1) After allyl glycidyl ether (a1) is diluted with the first organic solvent dichloromethane, the temperature is raised to reflux, and diethylamine (a2) is added dropwise to react; wherein, by the amount of substance, n (a1):n(a2)=1:1.5;

[0096] (2) After the dropwise addition was completed, the reaction was continued for 5 hours to obtain a crude product of 1-(allyloxy)-3-(diethylamino)propan-2-ol (a3);

[0097] (3) with reduced pressure distillation, remove the first organic solvent methylene chloride and excess diethylamine, obtain purer a3;

[0098] (4) After diluting a3 with the second organic solvent toluene, slowly drop bromoethane (a4) at 80°C; continue the reaction for 8 hours to obtain 3-(allyloxy)-N,N, N-triethyl-2-hydroxypropane-1-ammonium bromide (MOC) crude product; Wherein, by the am...

Embodiment 3

[0125] 1. Preparation of cationic monomer 3-(allyloxy)-N,N,N-triethyl-2-hydroxypropane ammonium bromide (MOC)

[0126] The preparation method of MOC comprises the steps:

[0127] (1) After allyl glycidyl ether (a1) is diluted with the first organic solvent dichloromethane, the temperature is raised to reflux, and diethylamine (a2) is added dropwise to react; wherein, by the amount of substance, n (a1):n(a2)=1:1.3;

[0128] (2) After the dropwise addition was completed, the reaction was continued for 5 hours to obtain a crude product of 1-(allyloxy)-3-(diethylamino)propan-2-ol (a3);

[0129] (3) with reduced pressure distillation, remove the first organic solvent methylene chloride and excess diethylamine, obtain purer a3;

[0130] (4) After diluting a3 with the second organic solvent toluene, slowly drop bromoethane (a4) at 80°C; continue the reaction for 7 hours to obtain 3-(allyloxy)-N,N, N-triethyl-2-hydroxypropane-1-ammonium bromide (MOC) crude product; Wherein, by the ...

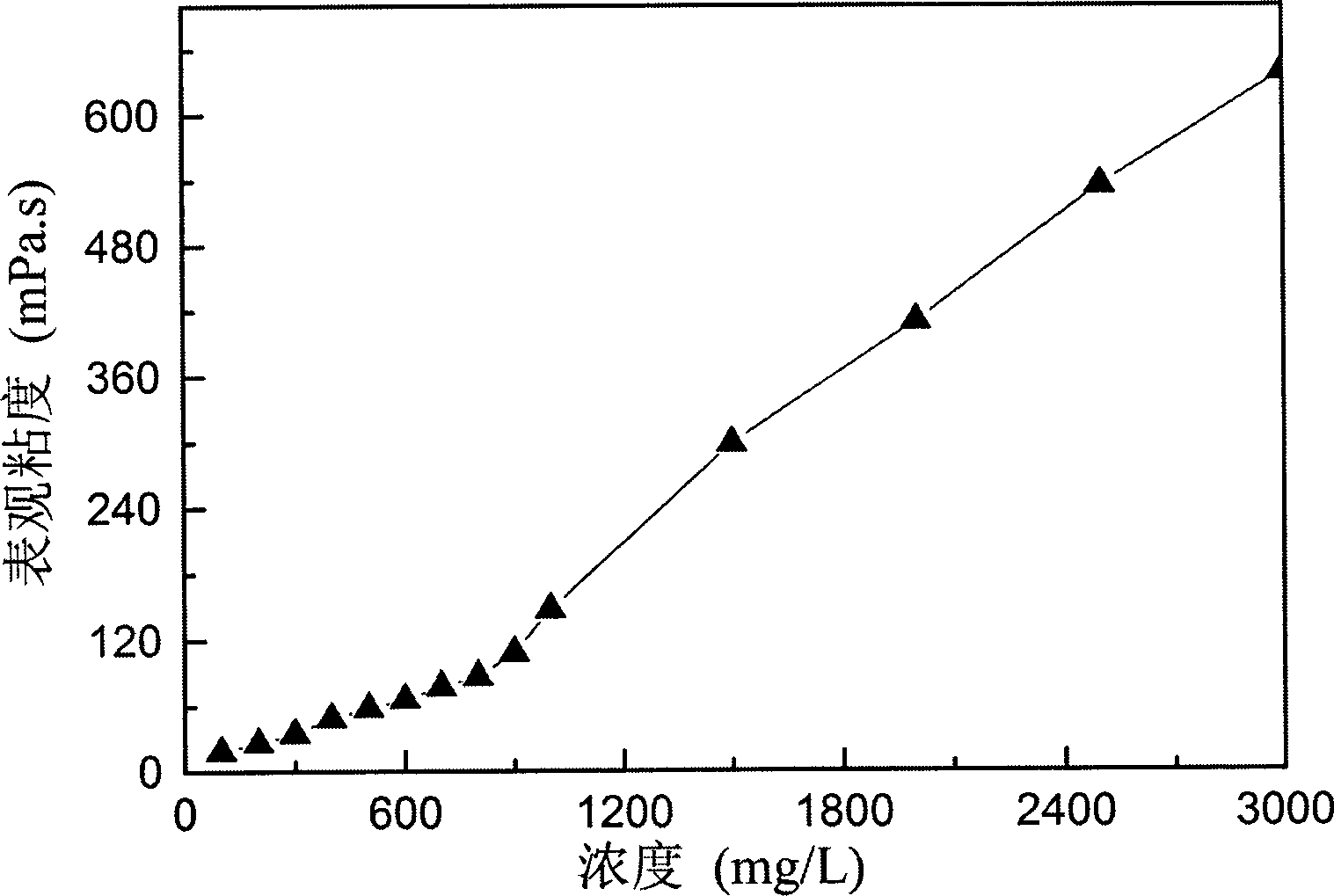

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com