Superstrong tramp oil resistance semisynthesis metal cutting liquid

A metal cutting fluid, semi-synthetic technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of exacerbating the deterioration speed of the used fluid, poor anti-miscellaneous oil performance, and stability problems, so as to reduce the stickiness of chips knot, excellent anti-corrosion performance, and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

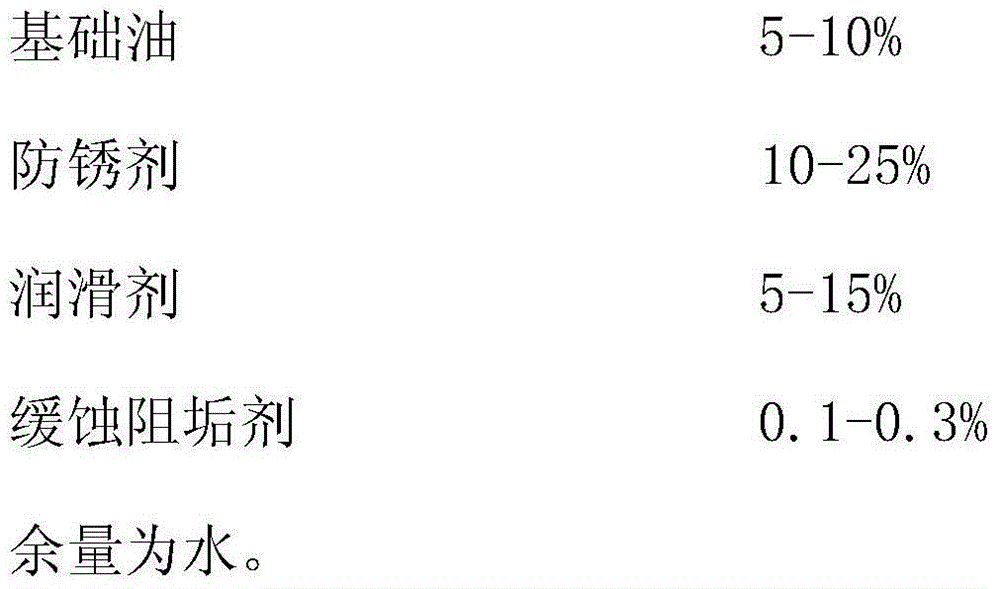

[0023] A semi-synthetic metal cutting fluid with super anti-miscellaneous oil, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0024]

[0025]

[0026] Among them, the base oil is mineral oil; the antirust agent is monoethanolamine borate, triethanolamine amide caproate, and one or more mixtures of dibasic fatty acids, such as a mixture of monoethanolamine borate, triethanolamine amide caproate, and dibasic fatty acids ; The lubricant is a single polyether; the corrosion and scale inhibitor is methyl benzotriazole.

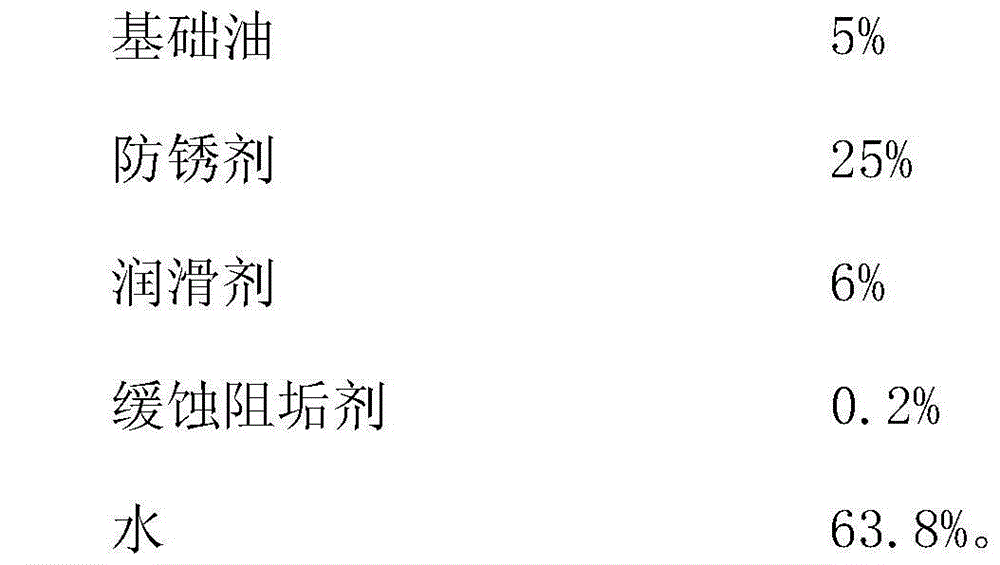

Embodiment 2

[0028]

[0029] Among them, the base oil is mineral oil; the antirust agent is boric acid monoethanolamine; the lubricant is a mixture of two polyethers; the corrosion and scale inhibitor is methyl benzotriazole.

Embodiment 3

[0031]

[0032] Among them, the base oil is mineral oil; the antirust agent is triethanolamine amide caproate; the lubricant is a mixture of three polyethers; the corrosion and scale inhibitor is methyl benzotriazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com