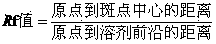

Method for semi-quantitative determination of ethyl carbamate through thin layer chromatography

A urethane and thin-layer chromatography technique, which is applied in the field of urethane content detection, can solve the problems of high professional and technical requirements for personnel, complicated pretreatment methods, expensive equipment and other problems, and achieves that the reaction conditions are easy to control and easy to use. Operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take out the thin-layer silica gel plate 5cm×10cm, activate it in an oven at 110°C for half an hour, and put it in a desiccator for later use;

[0029] (2) Prepare developer (methyl tert-butyl ether: petroleum ether: methanol = 5:7:3 (volume ratio), pour it into a double-slot thin-layer chromatography development cylinder after stirring, and let it stand for at least half an hour to make the saturation;

[0030] (3) Prepare fluorescent derivative solution, cinnamaldehyde 160μL, acetone 40ml, phosphoric acid 2.4ml in a small beaker, stir for later use;

[0031] (4) Take out the thin-layer board, spot the sample at 1cm from the lower end of the thin-layer board, and mark with a pencil 2cm from the upper end of the thin-layer board as the unfolding front, and place the sample. The first sample point is 20μL urethane standard solution (5mg / L, 40% ethanol aqueous solution), and the second point is placed at a distance of 2cm from the first point, and the sample is 20μL ...

Embodiment 2

[0036] (1) Take out the thin-layer silica gel plate 5cm×10cm, activate it in an oven at 110°C for half an hour, and put it in a desiccator for later use;

[0037](2) Prepare developing agent methyl tert-butyl ether: petroleum ether: methanol = 5:7:3 (volume ratio), pour it into a thin layer developing tank after stirring, and let it stand for at least half an hour to make it saturated;

[0038] (3) Prepare fluorescent derivative solution, cinnamaldehyde 160μL, acetone 40ml, phosphoric acid 2.4ml in a small beaker, stir for later use;

[0039] (4) Take out the thin-layer board, spot the sample at 1cm from the lower end of the thin-layer board, and mark with a pencil 2cm from the upper end of the thin-layer board as the unfolding front, and place the sample. The first sample point is 20μL urethane standard solution (5mg / L, 40% ethanol aqueous solution), and the second point is placed at a distance of 2cm from the first point, and the sample is 20μL urethane standard solution (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com