Doping method

A doped layer and impurity technology, applied in the field of doping, can solve the problems of poor process applicability, deteriorated solar cell performance, too high requirements for silicon wafer quality and purity, and achieves reduction of doping concentration, reduction of defect density, improvement of performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

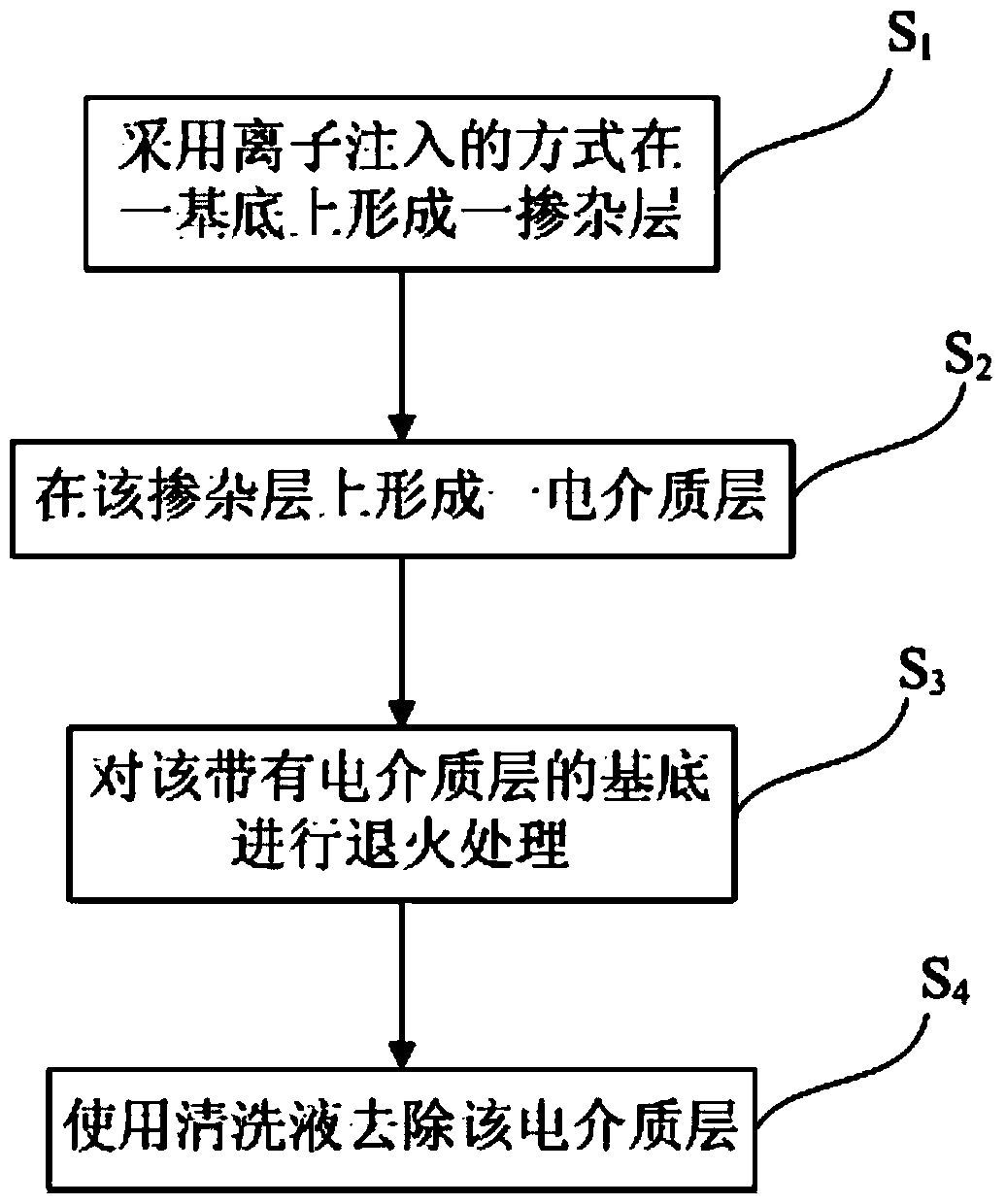

[0045] refer to figure 1 , the doping method described in this embodiment, comprising the following steps:

[0046] Step S 1 . Forming a doped layer on a substrate by means of ion implantation;

[0047] Step S 2 1. Forming a dielectric layer on the doped layer, wherein silicon nitride is formed by PECVD using silane and ammonia as the dielectric layer, and the thickness of the silicon nitride is 40nm;

[0048] Step S 3 1. Perform annealing treatment on the substrate with the dielectric layer, the annealing temperature is 850° C., and the annealing time is 60 minutes;

[0049] Step S 4 , using hydrofluoric acid as a cleaning solution to remove the dielectric layer.

[0050] The silicon nitride can uniformly reduce the doping concentration on the surface of the substrate, and the use of this doping method to manufacture solar cells will help reduce the recombination between the surface of the solar cell and the junction region. In addition, the silicon nitride also contri...

Embodiment 2

[0052] The principle of embodiment 2 is the same as embodiment 1, the only difference is:

[0053] After ion implantation, step S 2A cleaning step is also included before, to remove impurities formed by doping ions and / or metal impurities on the surface, back or sides of the substrate.

[0054] Refer to Example 1 for all the other unmentioned parts.

Embodiment 3

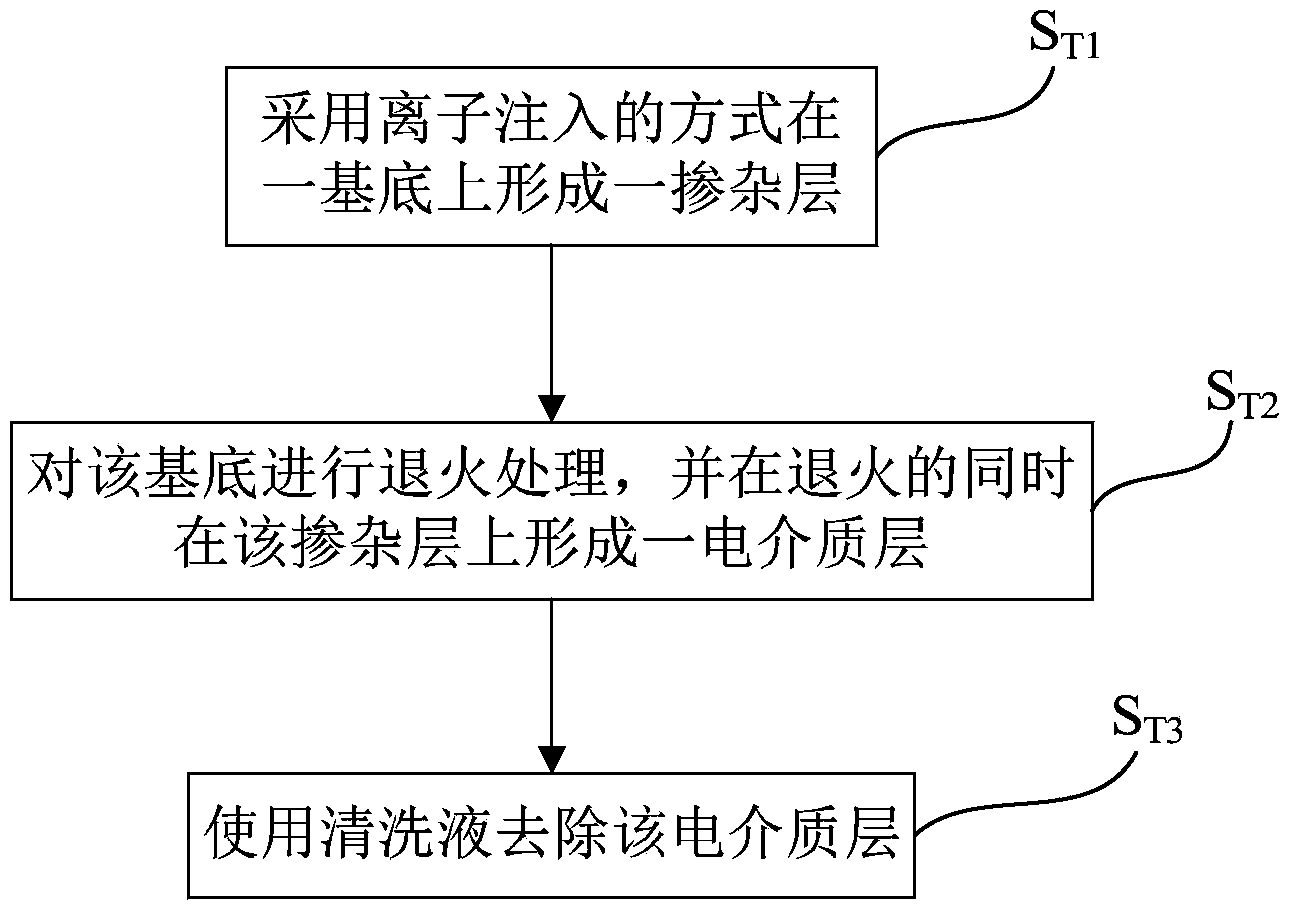

[0056] refer to figure 2 , the basic principle of embodiment 3 is the same as that of embodiment 1, the only difference is:

[0057] Step S T1 . Forming a doped layer on a substrate by means of ion implantation;

[0058] Step S T2 1. Perform annealing treatment on the substrate, and form a dielectric layer on the doped layer while annealing, wherein ammonia gas and oxygen gas are passed through during the annealing process to form silicon oxynitride as the dielectric layer;

[0059] Step S T3 , using a cleaning solution to remove the dielectric layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com