ANODE MATERIAL, ANODE, BATTERY, AND METHODS OF MANUFACTURING the anode material, the anode and the battery.

A negative electrode material and negative electrode technology, applied in secondary battery manufacturing, batteries, secondary batteries, etc., can solve the problems of reducing cycle characteristics, increasing the volume density of the negative electrode active material layer, and thickening the negative electrode active material layer, so as to suppress decomposition. Effects of reaction, improvement of chemical stability, improvement of cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

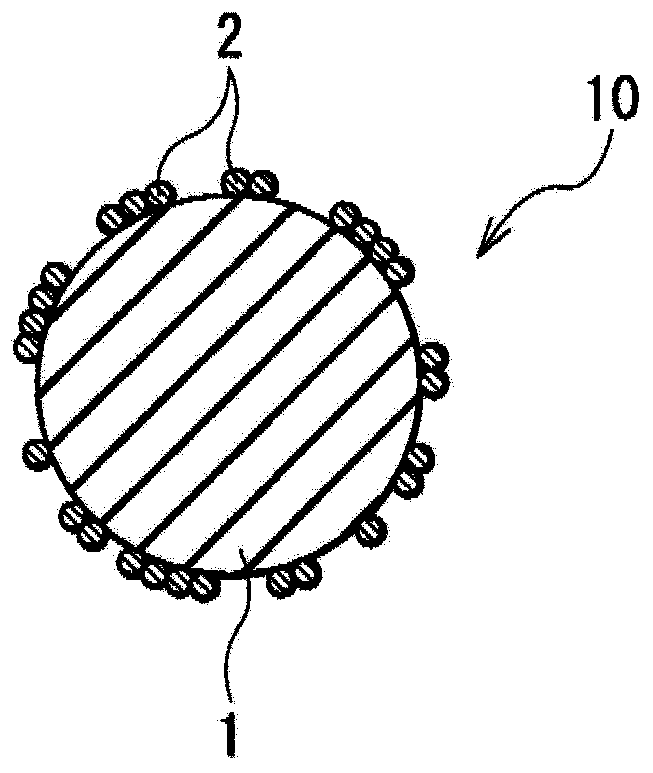

[0034] figure 1 A cross-sectional view of the negative electrode material according to the first embodiment of the present invention is schematically shown. The negative electrode material 10 is used, for example, in an electrochemical device including a negative electrode, such as a battery. The negative electrode material 10 has a negative electrode active material 1 capable of intercalating and deintercalating electrode reactants and a plurality of coated particles 2 disposed thereon.

[0035] The negative electrode active material 1 contains one or more materials capable of intercalating and deintercalating electrode reactants, and includes, for example, a carbon material. In carbon materials, changes in crystal structure during electrode reactions (intercalation and deintercalation of electrode reactants) are very small, resulting in high energy density. The type of electrode reactant can be selected arbitrarily. For example, when the negative electrode material is use...

no. 2 example

[0117] Hereinafter, a description will be given of a second embodiment of the present invention.

[0118] The negative electrode material of this embodiment has a structure similar to that of the negative electrode material of the first embodiment (refer to figure 1 ), the difference is that the constituent materials of the negative electrode active material 1 are different.

[0119] The negative electrode active material 1 contains, for example, a material containing at least one of a metal element and a metalloid element as one or more materials capable of intercalating and deintercalating electrode reactants, because thereby a high energy density can be obtained . Such a material containing at least one of a metal element and a metalloid element may be a single substance, an alloy, or a compound of a metal element or a metalloid element, or may at least partially have one or more phases thereof.

[0120] The alloy in the present invention includes not only the alloy compo...

example 1-1

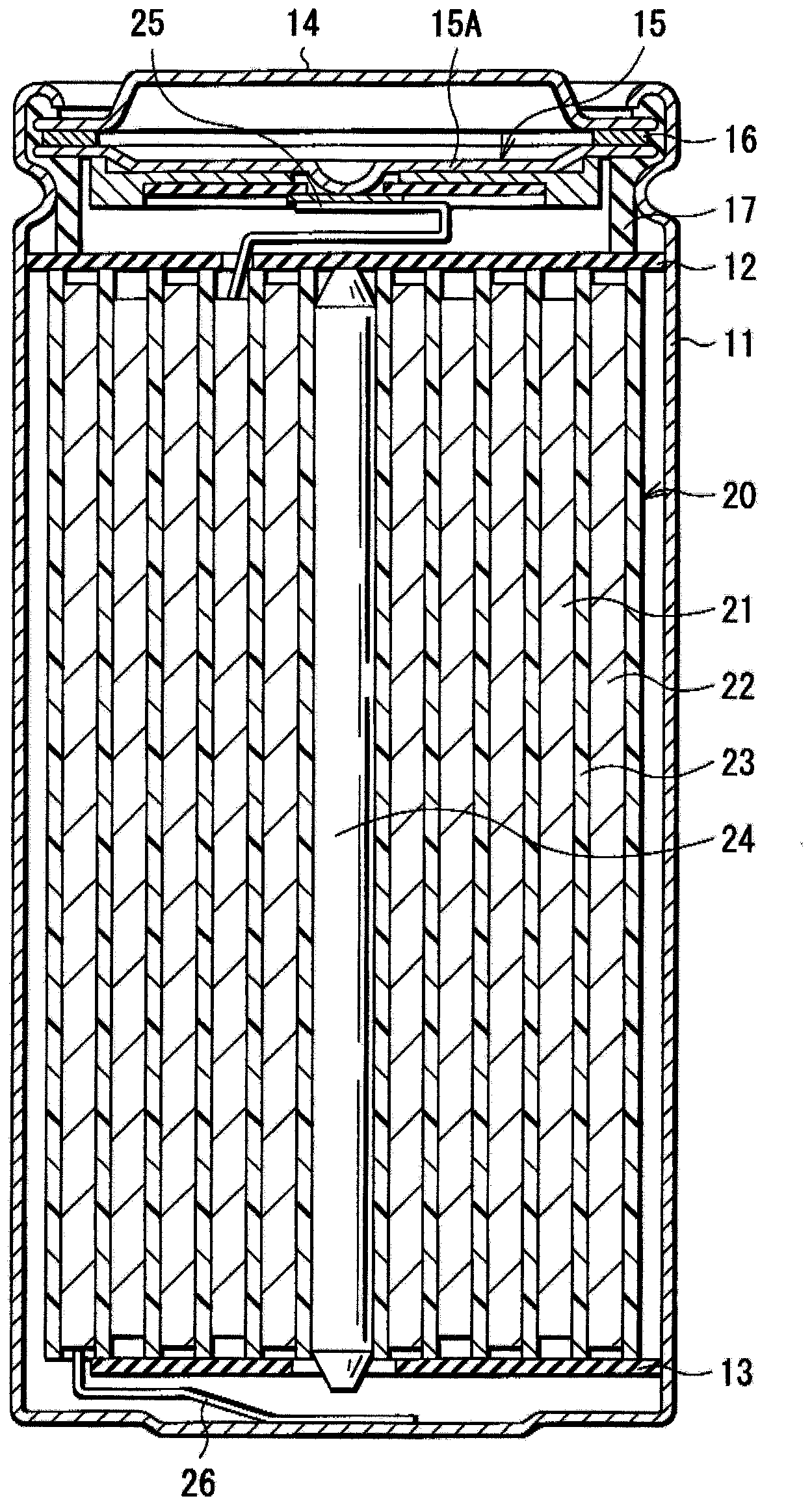

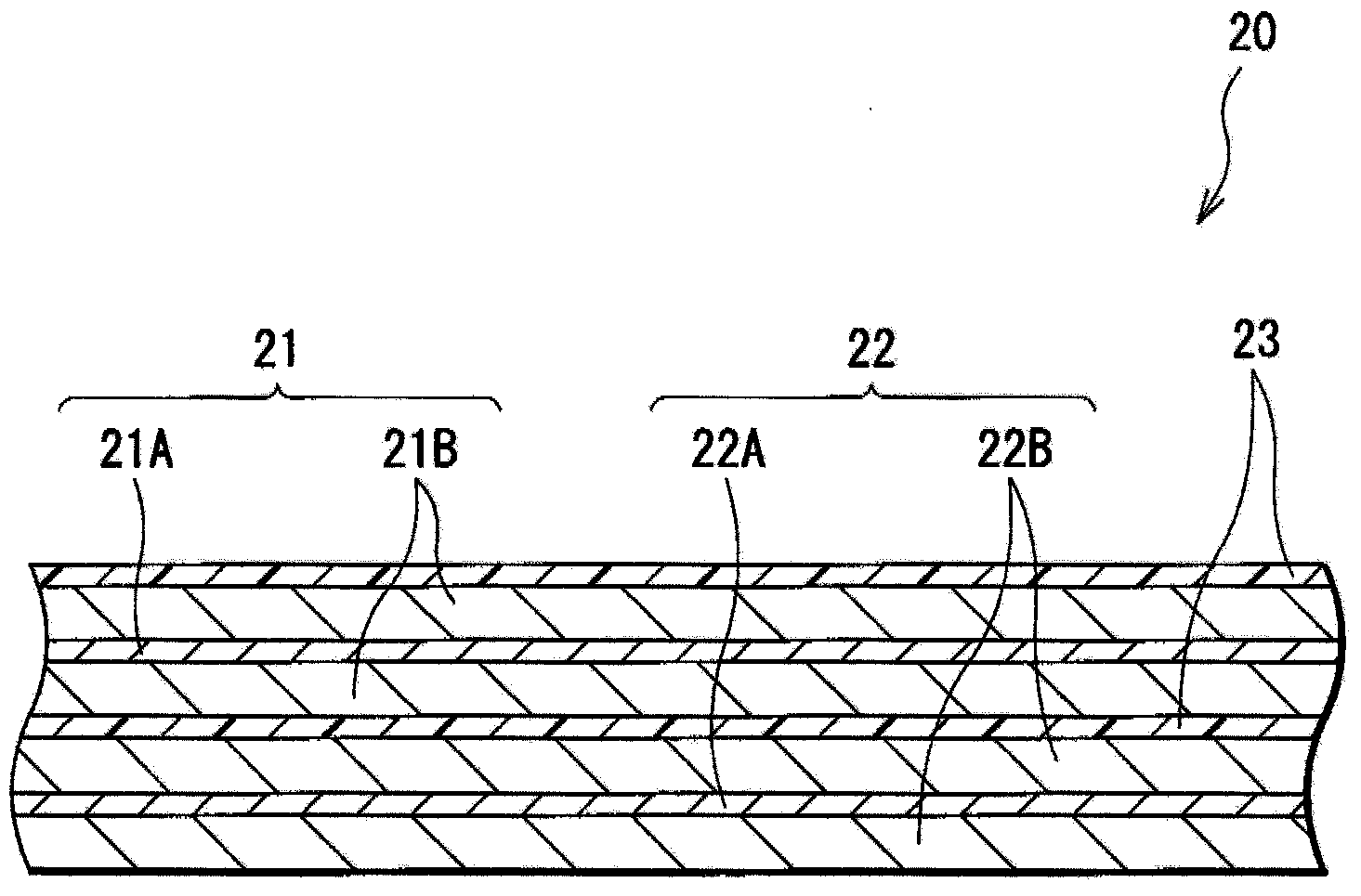

[0142] Figure 2 to Figure 4 The illustrated cylindrical secondary battery was manufactured in the following steps. This secondary battery is manufactured as a lithium ion secondary battery in which the capacity of the negative electrode 34 is expressed based on intercalation and deintercalation of lithium.

[0143] First, the positive electrode 21 is formed. First, lithium carbonate (Li 2 CO 3 ) and cobalt carbonate (CoCO 3 ) are mixed in a molar ratio of 0.5:1. Thereafter, the mixture was fired at 900° C. in air for 5 hours. Thus, lithium cobalt composite oxide (LiCoO 2 ). When the lithium-cobalt composite oxide was analyzed by the X-ray diffraction method, the peaks obtained were completely consistent with the peaks recorded in the documents of the Joint Committee of Powder Diffraction Standard (JCPDS). Subsequently, the lithium cobalt composite oxide was pulverized into powder. After that, 95 parts by weight of lithium-cobalt composite oxide powder and 5 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com