Dispersion preparation containing colloidal bismuth pectin and preparation method thereof

A technology of colloidal bismuth pectin and preparations, which is applied in the directions of medical preparations containing active ingredients, medical preparations without active ingredients, and pill delivery, etc., can solve the problems such as dispersible tablets no longer meet the requirements, and shorten the disintegration time limit. , the effect of speeding up and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Prescription: 324.7g colloidal bismuth pectin, 25.0g low-substituted hydroxypropyl cellulose, 80.8g microcrystalline cellulose, 15.0g calcium sulfate dihydrate, 27.5g citric acid monohydrate, 22.0g sodium bicarbonate, 5.0g talc powder , 50% ethanol 300ml. Made into 1000 tablets, each weighing 500mg.

[0051] Preparation process: crush the raw and auxiliary materials and pass through a 100-mesh sieve. Weigh the prescription amount of colloidal bismuth pectin, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, calcium sulfate dihydrate, and sodium bicarbonate and mix evenly; add the prescription amount of 50% ethanol-made soft material, pass through a 24-mesh sieve to granulate , baked at 60°C for 2 hours, sieved with a 24-mesh sieve, added citric acid monohydrate and talcum powder, and mixed evenly; determined drug content, pressed into tablets, coated with film, tested, and packaged.

[0052] Test indicators: hardness 3.0±0.5kg, dispersion uniformity...

Embodiment 2

[0054] Prescription: 324.7g colloidal bismuth pectin, 26.5g low-substituted hydroxypropyl cellulose, 98.0g microcrystalline cellulose, 15.9g calcium sulfate dihydrate, 33.1g anhydrous citric acid, 26.5g sodium bicarbonate, 5.3g talcum powder . Made into 1000 tablets, each weighing 530mg.

[0055] Preparation process: crush the raw and auxiliary materials and pass through a 100-mesh sieve. Weigh the prescribed amount of colloidal bismuth pectin, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, calcium sulfate dihydrate, sodium bicarbonate, anhydrous citric acid, and talcum powder, mix evenly, determine the drug content, compress tablets, and test ,Package.

[0056] Test indicators: hardness 3.0±0.5kg, dispersion uniformity 102s, dissolution rate 81.64%, colloidal stability and weight difference meet the requirements.

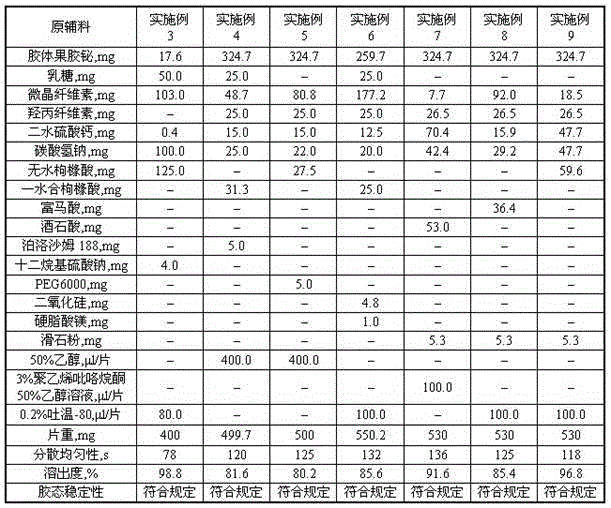

Embodiment 3~9

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com