Method for measuring free bismuth in colloidal bismuth pectin or preparation containing colloidal bismuth pectin

A colloidal pectin bismuth and preparation technology, applied in the field of free bismuth determination, can solve problems such as difficulty and poor reproducibility of measurement results, and achieve the effect of simple method, easy operation and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

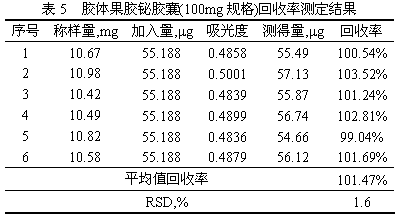

[0044] Embodiment 1: Determination of free bismuth content in colloidal pectin bismuth bulk drug.

[0045] 1) Preparation of chromogenic solution: Take about 2.5g of ascorbic acid and about 12.5g of potassium iodide, put them in a 200ml volumetric flask, add about 100ml of water, shake to dissolve, add 25ml of 1mol / L nitric acid solution, dilute with water and set the volume to the mark, Prepare a solution containing 1.25% ascorbic acid and 6.25% potassium iodide.

[0046] 2) Preparation of bismuth reference solution: Take about 250 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute to the mark with water, and use it as a bismuth standard stock solution. Precisely measure 1ml of bismuth standard stock solution, put it in a 50ml volumetric flask, add 1mol / L nitric acid solution to dilute to the mark, and make a solution containing about 50μg of bismuth per 1ml, as the bismuth standard solution. Precisely...

Embodiment 2

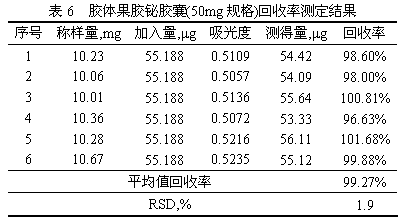

[0051] Embodiment 2: Determination of free bismuth content in colloidal pectin bismuth capsules (specification 40 mg, calculated as bismuth).

[0052] 1) Preparation of chromogenic solution: Take 5g of ascorbic acid and 12.5g of potassium iodide, put them in a 200ml volumetric flask, add 100ml of water, shake to dissolve, add 25ml of 1mol / L nitric acid solution, dilute with water and set the volume to the mark to prepare ascorbic acid 2.5 %, potassium iodide 6.25% chromogenic solution.

[0053] 2) Preparation of bismuth reference substance solution: Take about 275 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute to the mark with water, and use it as a bismuth standard stock solution. Precisely measure 2ml of bismuth standard stock solution, put it in a 100ml volumetric flask, add 0.8mol / L nitric acid solution to dilute to the mark, and make a solution containing about 55μg of bismuth per 1ml, as the bi...

Embodiment 3

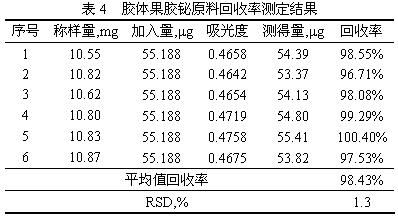

[0057] Embodiment 3: Determination of free bismuth content in colloidal pectin bismuth capsules (specification 50 mg, calculated as bismuth).

[0058] 1) Preparation of chromogenic solution: Take 20g of ascorbic acid and 50g of potassium iodide, put them in a 200ml volumetric flask, add 100ml of water, shake to dissolve, add 25ml of 1mol / L acetic acid solution, dilute with water and set the volume to the mark to make 10% ascorbic acid , Potassium iodide 25% chromogenic solution.

[0059] 2) Preparation of bismuth reference substance solution: Take about 275 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute to the mark with water, and use it as a bismuth standard stock solution. Precisely measure 1ml of bismuth standard stock solution, put it in a 100ml volumetric flask, add 1mol / L nitric acid solution to dilute to the mark, and make a solution containing about 27.5μg of bismuth per 1ml, as the bismuth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com