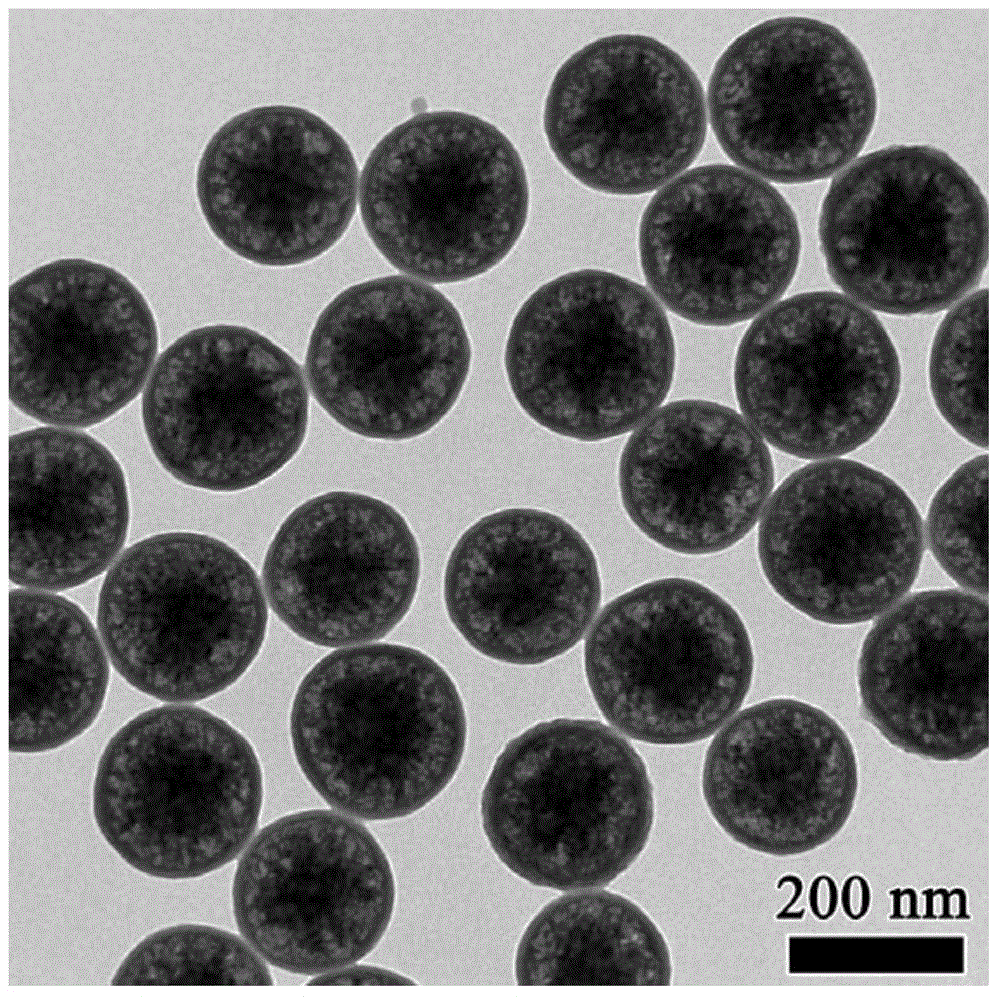

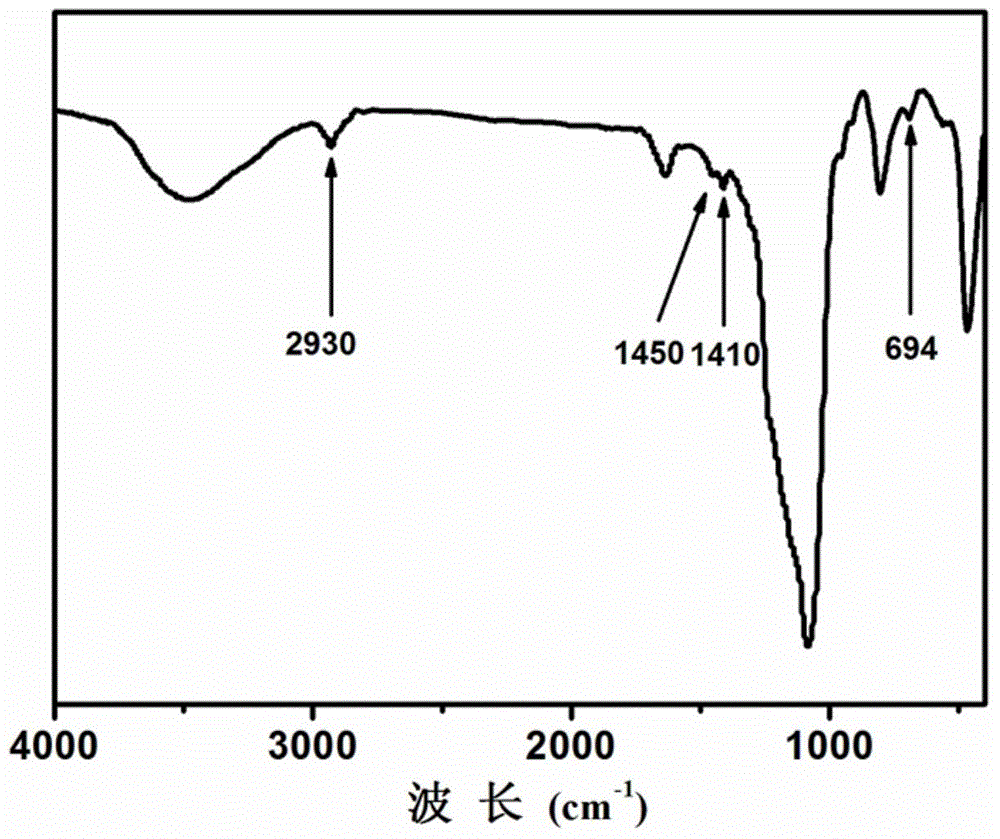

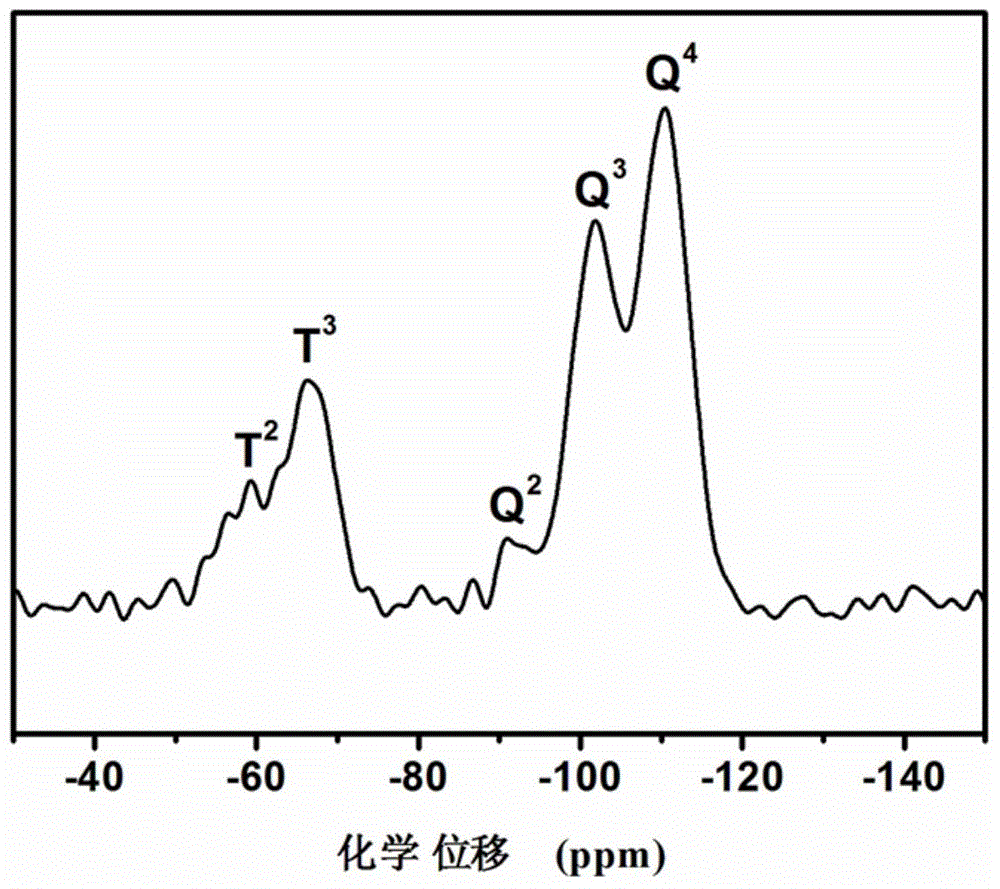

Long-chain-thioether-bond-containing mesoporous organic-inorganic hybrid ball of core-hollow-shell structure and preparation method thereof

A chain thioether and mesoporous technology, which is applied in the field of mesoporous organic-inorganic hybrid spheres and its preparation, can solve problems such as the inability to prepare silicon-based materials, and overcome the inability to transform into egg yolk-eggshell mechanisms and synthesis methods The effect of simplicity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percent concentration is 25%) mixed with 30ml ethanol and 75ml water, then 0.16g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.25ml orthosilicon was mixed at 35°C with 980rpm stirring Acid tetraethyl ester and 0.1ml of bis-[3-(triethoxysilyl)propyl]tetrasulfide were added to the aqueous alcohol solution and reacted for 24h to obtain a white solution. The solution was centrifuged and washed once with ethanol;

[0039] (2) Add ethanol to the product obtained in step (1) to dilute to 30ml, take 5ml and centrifuge, disperse in 30ml of water, transfer to a reaction kettle, and react overnight in an oven at 150°C and 1.0MPa;

[0040] (3) The reaction product obtained in step (2) was centrifuged, washed once with ethanol, transferred to a mixed solution of 500 μl concentrated hydrochloric acid and 250 ml ethanol, and heated in a water bath a...

Embodiment 2

[0046] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percent concentration is 25%) mixed with 30ml ethanol and 75ml water, then 0.08g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.25ml orthosilicon Acid tetraethyl ester and 0.1ml of bis-[3-(triethoxysilyl)propyl]tetrasulfide were added to the aqueous alcohol solution and reacted for 24h to obtain a white solution. The solution was centrifuged and washed once with ethanol;

[0047] (2) Add ethanol to the product obtained in step (1) to dilute to 30ml, take 5ml and centrifuge, disperse in 30ml of water, transfer to a reaction kettle, and react overnight in an oven at 150°C and 1.0MPa;

[0048] (3) The reaction product obtained in step (2) was centrifuged, washed once with ethanol, transferred to a mixed solution of 500 μl concentrated hydrochloric acid and 250 ml ethanol, and heated in a water bath at 60° C. for 3 hours;

[0049] (4) Ste...

Embodiment 3

[0052] (1) Mix 1ml of concentrated ammonia water (the NH contained in the concentrated ammonia water 3 The mass percentage concentration is 25%) mixed with 30ml ethanol and 75ml water, then 0.12g hexadecyltrimethylammonium bromide was dissolved in the mixed solution, and 0.25ml orthosilicon Acid tetraethyl ester and 0.1ml of bis-[3-(triethoxysilyl)propyl]tetrasulfide were added to the aqueous alcohol solution and reacted for 24h to obtain a white solution. The solution was centrifuged and washed once with ethanol;

[0053] (2) Add ethanol to the product obtained in step (1) to dilute to 30ml, take 5ml and centrifuge, disperse in 30ml of water, transfer to a reaction kettle, and react overnight in an oven at 150°C and 1.0MPa;

[0054] (3) The reaction product obtained in step (2) was centrifuged, washed once with ethanol, transferred to a mixed solution of 500 μl concentrated hydrochloric acid and 250 ml ethanol, and heated in a water bath at 60° C. for 3 hours;

[0055] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com