Heat treatment method for Mg-Al-Zn-Y rare-earth magnesium alloy

A heat treatment method and rare earth magnesium technology, applied in the field of magnesium alloy processing, can solve the problems of residual stress of deformed materials, poor formability, and reduction of workpiece formability by extrusion ratio, so as to improve mechanical properties, high temperature strength and creep resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The Mg-Al-Zn-Y rare earth magnesium alloy ingot is hot-extruded, the extrusion temperature is 335°C, and the extrusion ratio is 5:1; the extruded Mg-Al-Zn-Y rare earth magnesium alloy is kept at 402°C for 5h , and then air-cooled to room temperature; then it was kept at 180°C for 18h, and finally air-cooled. After the above heat treatment, the tensile strength of the extruded Mg-Al-Zn-Y rare earth magnesium alloy is 376.09MPa, the elongation is 11.6%, and the hardness is 98.86HV.

Embodiment 2

[0018] The Mg-Al-Zn-Y rare earth magnesium alloy ingot is hot-extruded, the extrusion temperature is 340°C, and the extrusion ratio is 5:1; the extruded Mg-Al-Zn-Y rare earth magnesium alloy is kept at 405°C for 6h , and then air-cooled to room temperature; then it was kept at 190°C for 19h, and finally air-cooled. After the above heat treatment, the tensile strength of the extruded Mg-Al-Zn-Y rare earth magnesium alloy is 386.67MPa, the elongation is 12.8%, and the hardness is 106.48HV.

Embodiment 3

[0020] The Mg-Al-Zn-Y rare earth magnesium alloy ingot is hot-extruded, the extrusion temperature is 345°C, and the extrusion ratio is 6:1; the extruded Mg-Al-Zn-Y rare earth magnesium alloy is kept at 408°C for 7h , and then air-cooled to room temperature; then it was kept at 190°C for 18h, and finally air-cooled. After the above heat treatment, the tensile strength of the extruded Mg-Al-Zn-Y rare earth magnesium alloy is 380.26MPa, the elongation is 12.3%, and the hardness is 102.39HV.

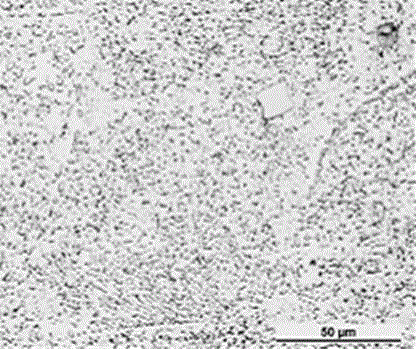

[0021] Samples were taken from the workpiece in Example 2, and the microstructure of the alloy was observed under an optical microscope after grinding, polishing, and corrosion, as shown in the accompanying drawings. It can be seen from the attached drawings that after the above heat treatment, the morphology and distribution of the β phase in the alloy are significantly improved, and there are diffuse distributions in the grain and grain boundaries, and the precipitated phases are more unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com