Cu2ZnSnS4 schottky diode structure and preparation method thereof

A technology of Schottky diodes and top electrodes, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as application limitations and device impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

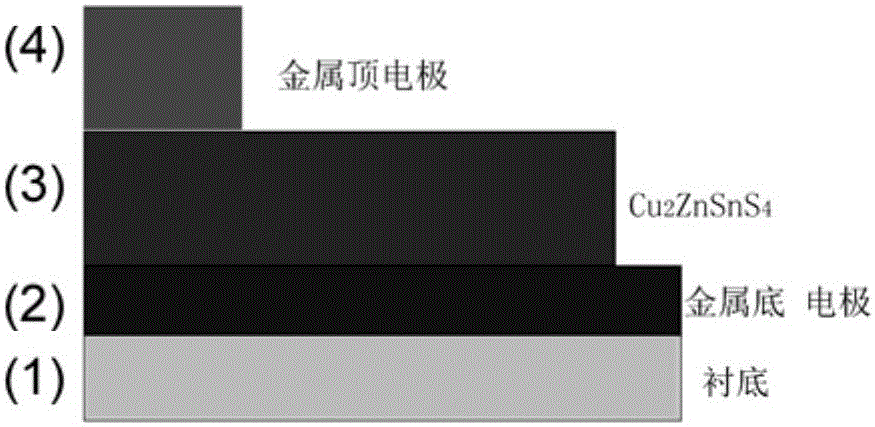

[0029] Example 1: Cu 2 ZnSnS 4 Fabrication of Schottky Diode Structures

[0030] (1) Cleaning the glass substrate 1, using acetone, ethanol and deionized water to perform ultrasonic cleaning for 20 minutes in sequence, and after the cleaning is completed, the glass substrate 1 is placed in deionized water for preservation for later use. The glass substrate 1 was blown dry with a nitrogen gun before use. The substrate may also be a silicon wafer substrate or a stainless steel flexible substrate or other suitable substrate.

[0031] (2) A metal bottom electrode molybdenum is deposited on the glass substrate 1 using a magnetron sputtering process to form a metal bottom electrode layer 2 . The deposition process of metal molybdenum is as follows: sputtering with a radio frequency power source, the sputtering power is 80W, and the argon gas pressure is 1.2Pa during sputtering. The metal bottom electrode molybdenum is deposited to a thickness of about 1 micron.

[0032] (3) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com