Lithium ion battery diaphragm for overcharge protection and preparation method thereof

A lithium-ion battery, overcharge protection technology, applied in secondary batteries, battery pack components, circuits, etc., to achieve the effects of good effect, easy mass production, and simple and controllable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

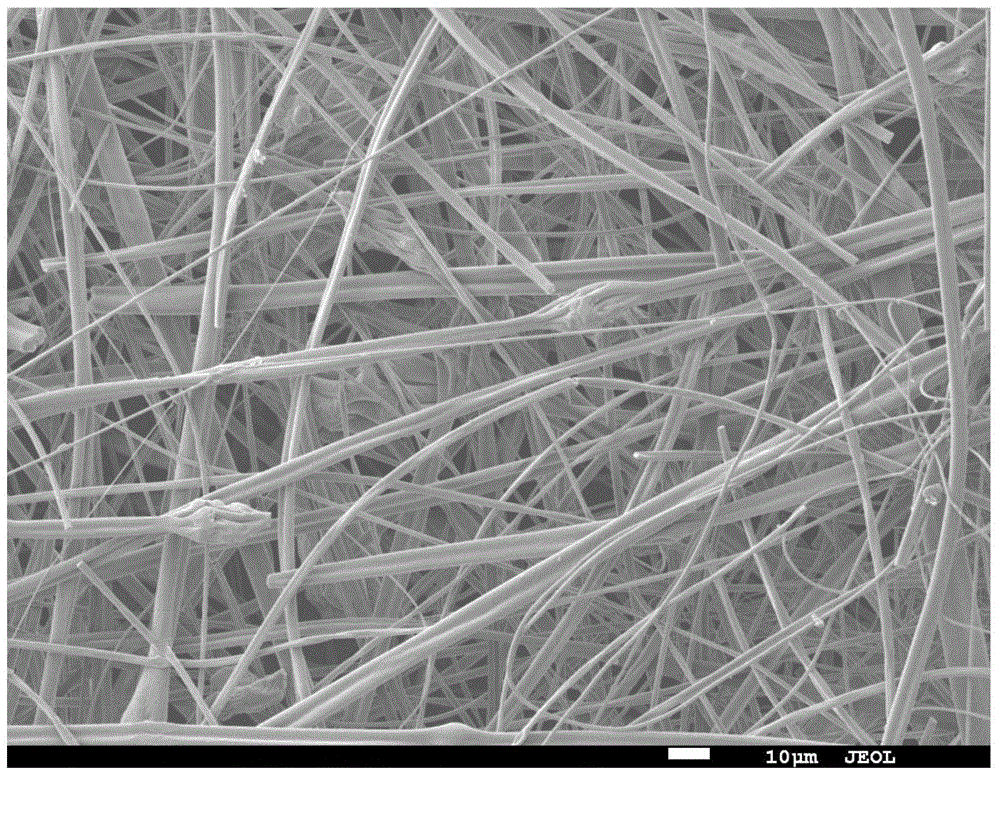

[0079] Mix fluorenecarbazole copolymer with triphenylamine-fluorene copolymer, polyvinylidene fluoride-copolymerization-hexafluoropropylene (PVDF-HFP), polyethylene oxide (PEO), and tin oxide in a mass ratio of 1:0.5:0.1 , where the mass ratio of fluorencarbazole copolymer to triphenylamine-fluorene copolymer is 9:1, and the mass ratio of PVDF-HFP to PEO is 5:1; then dissolved in chloroform and N,N-dimethylformamide (DMF), under the condition that the speed is 1300rpm, stir evenly, then heat to a temperature of 80°C and continue to stir until completely dissolved to obtain a mixture; the obtained mixture is electrostatically charged under the condition that the voltage is 25kV and the receiving distance is 20cm. After spinning, the product was collected by a flat current collector after 2 hours, then separated, formed into holes, and dried in a vacuum oven at 80°C for 12 hours to obtain a lithium-ion battery separator with a thickness of 50 μm.

[0080] Structural diagram such...

Embodiment 2

[0085] Mix fluorenebenzene copolymer with triphenylamine-fluorene copolymer, polyvinylidene fluoride-copolymerization-hexafluoropropylene (PVDF-HFP), polyacrylonitrile (PAN), and salicylic acid in a mass ratio of 1:8:0.5 , wherein the mass ratio of fluorenebenzene copolymer to triphenylamine-fluorene copolymer is 1:5, and the mass ratio of PVDF-HFP to PAN is 7:3; then dissolve in tetrachloromethane, N,N-dimethylethane In amide (DMAc) and N,N-dimethylformamide (DMF), stir evenly at a speed of 500 rpm, then heat to a temperature of 60°C and continue stirring until completely dissolved to obtain a mixture; the obtained mixture Under the condition that the voltage is 5kV and the receiving distance is 7cm, electrospinning, the product is collected in the form of a flat collector after 2 hours, and then 85% of the inactive components inside the product are removed by mass, and then separated, pore-formed, and Dry in a vacuum oven at 60° C. for 14 hours to obtain a lithium-ion batter...

Embodiment 3

[0089] The fluorenecarbazole copolymer and fluorenebenzene copolymer, polyvinylidene fluoride-copolymerization-hexafluoropropylene (PVDF-HFP), and glycerol are weighed according to the mass ratio of 1:15:10, wherein the fluorenecarbazole copolymer and The mass ratio of the fluorene benzene copolymer is 8:2; then the active polymer and the inactive polymer are respectively dissolved in N,N-dimethylformamide (DMF), stirred evenly at a speed of 1300rpm, and then heated Continue to stir at a temperature of 80°C until completely dissolved to obtain two mixtures; place the obtained two mixtures in a concentric electrospinning needle tip, and perform electrospinning under the conditions of a voltage of 15kV and a receiving distance of 20cm for 1 hour Finally, the product was collected by means of a solution spinning current collector, and then separated, formed into holes, and dried in a vacuum oven at 90° C. for 11 hours to obtain a lithium-ion battery separator with a thickness of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com