Preparation method for Nb-doped Li4T5O12 nano material

A nanomaterial and equipment technology, applied in the field of non-hydrolyzable sol-gel method, can solve the problems of affecting battery performance, easy enrichment of electrons, poor conductivity, etc., achieve stable cycle performance, avoid the use of complexing agents and strong acid catalysts, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

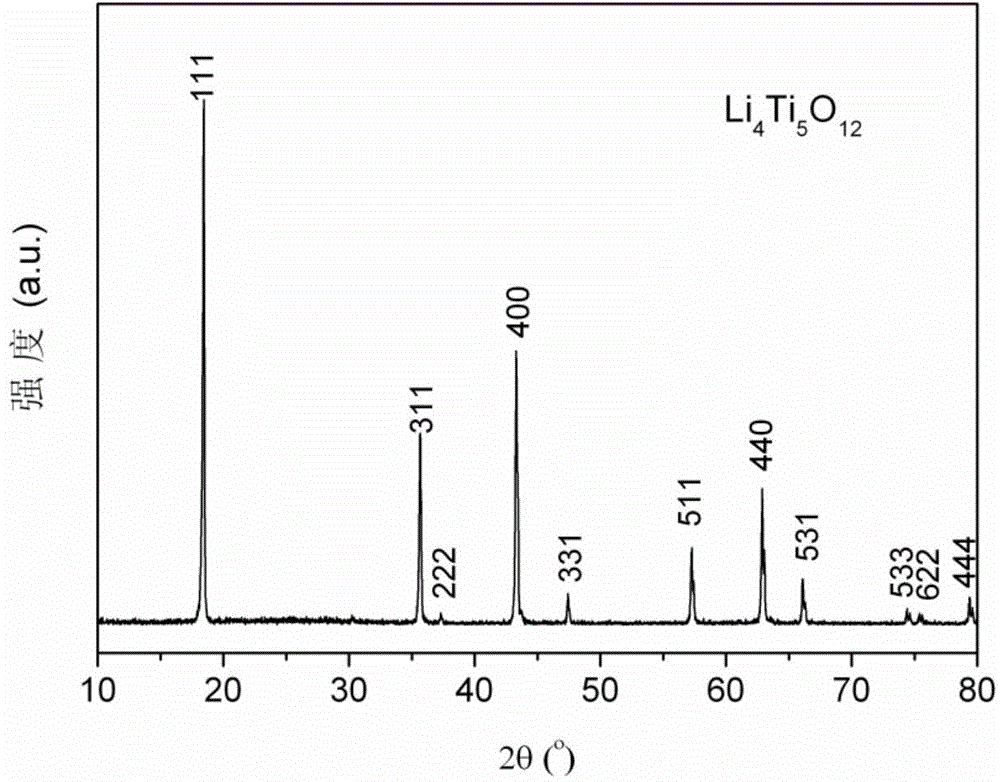

[0027] Example 1: Add 86mL of absolute ethanol into the reflux equipment, according to the molar ratio Li:Nb:Ti=4.0:0.01:4.99, add 5.692g tetraethyl titanate (analytical pure), 0.0135g chloride Niobium (analytical pure, anti-hydrolysis) and 0.8478g lithium chloride (analytical pure, pre-ground into fine powder), magnetically stirred until completely dissolved and in a clear state; then stirred for 20 minutes, and then the solution was first heated at 70°C, until reflux begins. Then adjust the temperature to 100°C, and reflux for 24 hours until the gel is formed, then stop the reflux, and take out the gel after cooling. The gel was dried at 200 °C to remove the solvent to obtain a black fluffy precursor of a black Nb-doped lithium titanate. The precursor was calcined in a muffle furnace at a high temperature of 650° C. for 5 hours to obtain white Nb-doped lithium titanate powder. figure 1 is the XRD pattern of the obtained sample. The position and relative intensity of each ...

Embodiment 2

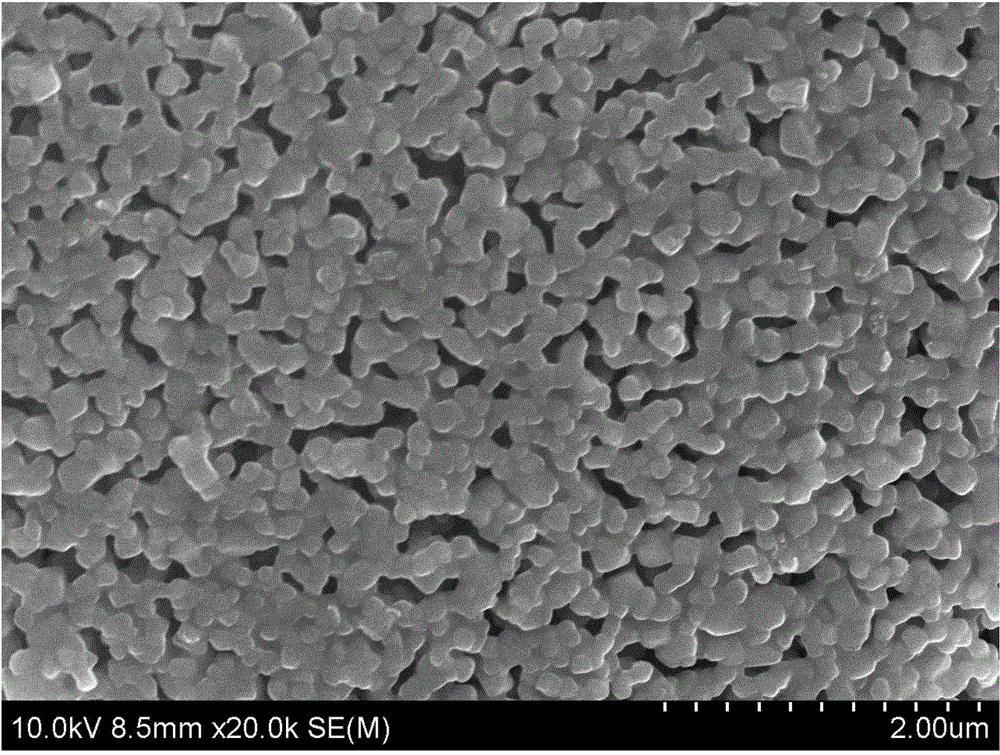

[0028] Example 2: Add 107.5mL of absolute ethanol into the reflux equipment, according to the molar ratio Li:Nb:Ti=4.2:0.05:4.95, add 8.423g tetra-n-butyl titanate (analytical pure), 0.0675g Niobium chloride (analytical pure, anti-hydrolysis) and 0.8902g lithium chloride (analytical pure, pre-ground into fine powder), magnetically stirred until completely dissolved and in a clear state; then stirred for 40 minutes, and then the solution was first heated at 80°C Heat until reflux begins. Then adjust the temperature to 120°C, and reflux for 30 hours until the gel is formed, then stop the reflux, and take out the gel after cooling. The gel was dried at 250 °C to remove the solvent to obtain a black fluffy precursor of black Nb-doped lithium titanate. The precursor was calcined in a muffle furnace for 5 hours at 700° C. to obtain white Nb-doped lithium titanate powder. figure 2 The SEM image of the material shows that the dispersion of the material is very good and the structur...

Embodiment 3

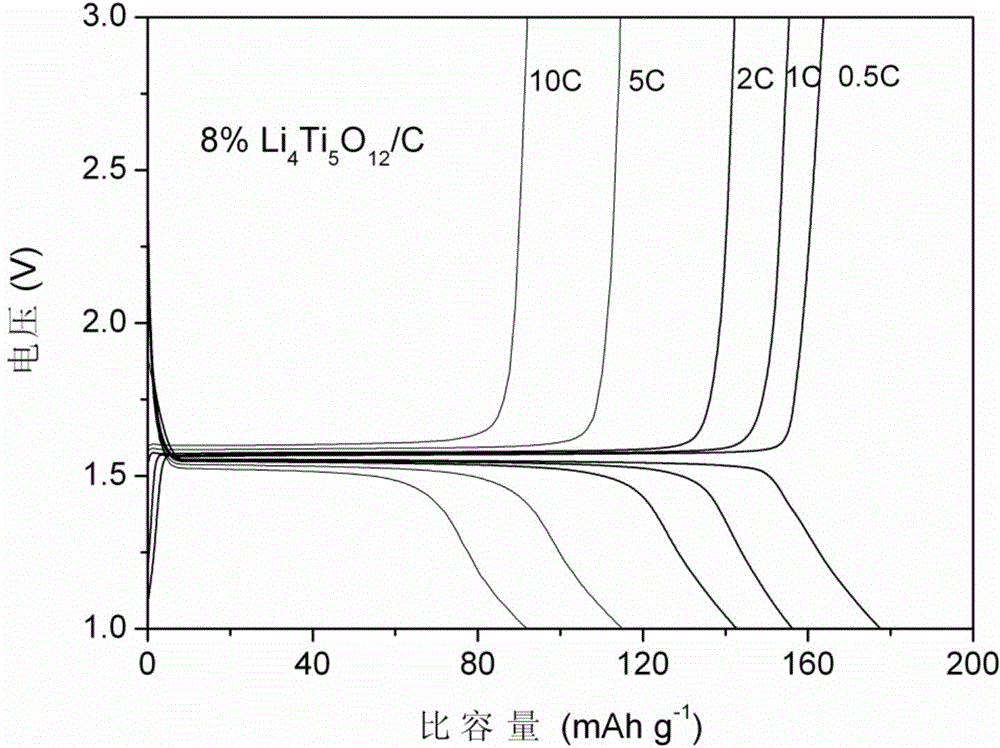

[0029]Example 3: Add 129mL of absolute ethanol into the reflux device, according to the molar ratio Li:Nb:Ti=4.5:0.1:4.90, add 6.9634g tetraisopropyl titanate (analytical pure), 0.1351g Niobium chloride (analytical pure, anti-hydrolysis) and 0.9538g lithium chloride (analytical pure, pre-ground into fine powder), magnetically stirred until completely dissolved and in a clear state; then stirred for 30 minutes, and then the solution was first heated at 70°C Heat until reflux begins. Then adjust the temperature to 110°C, reflux for 36 hours, until the gel is formed, stop the reflux, and take out the gel after cooling. The gel was dried at 200 °C to remove the solvent to obtain a black fluffy precursor of a black Nb-doped lithium titanate. The precursor was calcined in a muffle furnace at a high temperature of 750° C. for 5 hours to obtain white Nb-doped lithium titanate powder. image 3 In order to use this material as the positive electrode and metal lithium as the negative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com