Acid-free storage battery taking lead as negative electrode

An acid battery and negative electrode technology, applied in the field of electrochemistry, can solve the problems of lead-acid battery pollution, poor safety performance of ammonium salt lead battery, high production cost, etc., and achieve the effects of excellent performance, excellent cycle performance, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

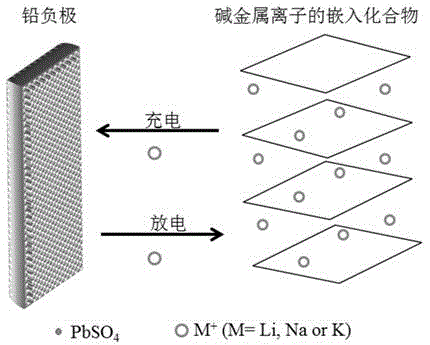

Method used

Image

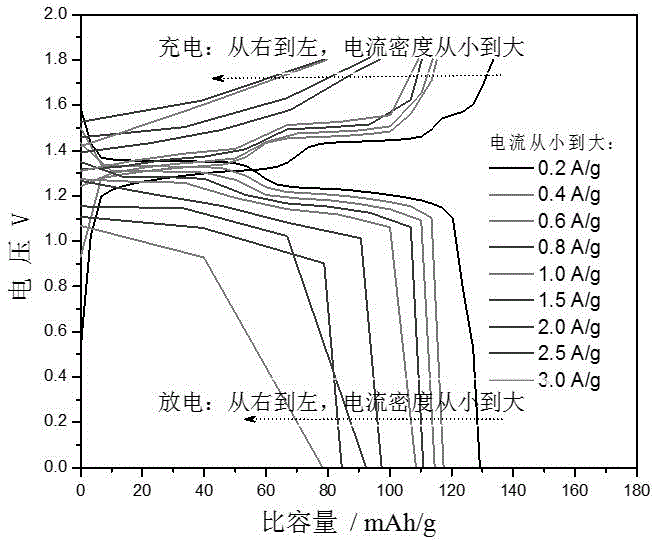

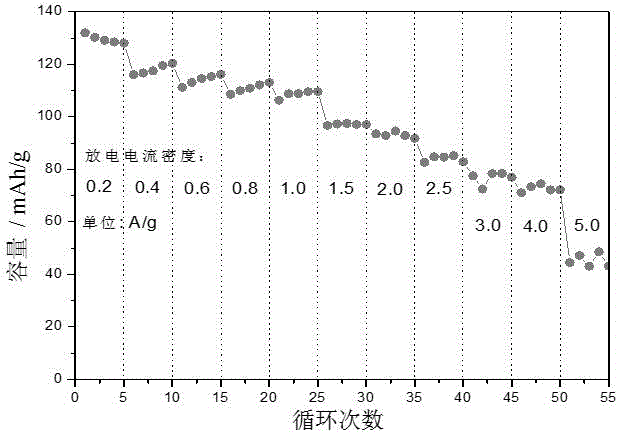

Examples

Embodiment 1

[0024] Metal lead is used as the negative electrode, and the active material of the positive electrode is LiMn 2 o 4 (75wt.%), PTFE as a binder (10wt.%), acetylene black as a conductive agent (15wt.%), mixed evenly, coated on a nickel grid, and then dried and immersed in 0.5 M Li with a pH of 7 2 SO 4 In the electrolyte composed of, so as to obtain lead as the negative electrode, LiMn 2 o 4 Lead charge and discharge battery for the positive electrode. The test was carried out with a current of 400 mA / g, and the charging was carried out at a constant current of 400 mA / g, charged to 1.8V, and then discharged at a constant current of 400 mA / g. After 50 cycles of activation, the capacity fades by 11% after 110 cycles. For the sake of comparison, these data are also summarized in Table 1.

Embodiment 2

[0026] In addition to changing the positive active material to K 0.3 MnO 2 , 0.5 M Li in the electrolyte 2 SO 4 Change to 2M KNO 3 Outside, other conditions are all identical with to embodiment 1, obtain taking lead as negative pole, K 0.3 MnO 2 positive battery. The test conditions are also the same as in Example 1. According to the test results, the same capacity fading of 12% after 50 activation cycles and 110 cycles was obtained. For the sake of comparison, these data are also summarized in Table 1.

Embodiment 3

[0028] In addition to changing the positive active material to NaFePO 4 , 0.5 M Li in the electrolyte 2 SO 4 Change to 1 M NaCl, negative electrode material is - calcium alloy (mass ratio is 98:2), other preparation conditions are all the same as to embodiment 1, obtain taking lead as negative electrode, NaFePO 4 positive battery. The test conditions are also the same as in Example 1. According to the test results, the capacity decay of 14% was also obtained after 50 activations and 110 cycles. For the sake of comparison, these data are also summarized in Table 1.

[0029] Table 1 The energy density of the above comparative examples and examples (according to the quality of the electrode active material)

[0030]

[0031] It can be seen from Table 1 that the capacity fading of the embodiment is less, and because the neutral electrolyte is less polluted than the acid electrolyte, the battery of the embodiment is safer and more reliable, and has good application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com