Preparation method of highly-ordered mesoporous carbon material

A highly ordered, mesoporous carbon technology, applied in the field of inorganic materials, can solve the problems of multi-time, long synthesis cycle, complex procedures, etc., and achieve the effects of large preparation, simple operation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

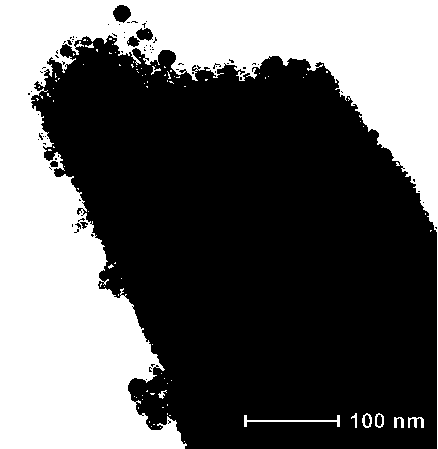

[0022] Example 1: 36g of iron oleate and 5.7g of oleic acid were dissolved in 200g of octadecene, and reacted at 320°C for 30min under the protection of nitrogen to obtain iron ferric oxide nanoparticles with a particle size of about 10nm. The obtained nanoparticles are dissolved in n-hexane, and the solvent is evaporated to obtain highly ordered oleic acid-coated nanomaterials. Calcining the obtained material at a high temperature of 500° C. for 2 hours can obtain highly ordered carbon-coated ferric oxide nanoparticles. The obtained material was etched away with ferric oxide with hydrochloric acid to obtain a mesoporous carbon material with a particle size of about 10 nm. Its specific surface area can be 1600m 2 / g.

Embodiment 2

[0023] Example 2: Dissolve 36g of iron oleate and 8.55g of oleic acid in 300g of octadecene, and react at 330°C for 60min under the protection of nitrogen to obtain iron ferric oxide nanoparticles with a particle size of about 14nm. The obtained nanoparticles are dissolved in n-hexane, and the solvent is evaporated to obtain highly ordered oleic acid-coated nanomaterials. Calcining the obtained material at a high temperature of 500° C. for 2 hours can obtain highly ordered carbon-coated ferric oxide nanoparticles. The obtained material was etched away with ferric oxide with hydrochloric acid to obtain a mesoporous carbon material with a particle size of about 14 nm.

Embodiment 3

[0024] Example 3: 72g of iron oleate and 5.7g of oleic acid were dissolved in 200g of hexadecene, and reacted at 280°C for 90min under the protection of nitrogen to obtain ferric oxide nanoparticles with a particle size of about 6nm. The obtained nanoparticles are dissolved in n-hexane, and the solvent is evaporated to obtain highly ordered oleic acid-coated nanomaterials. Calcining the obtained material at a high temperature of 500° C. for 2 hours can obtain highly ordered carbon-coated ferric oxide nanoparticles. The obtained material was etched away with ferric oxide with hydrochloric acid to obtain a mesoporous carbon material with a particle size of about 6 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com