Three-phase inversion composite busbar suitable for half-bridge module

A three-phase inverter and composite busbar technology, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of large stray inductance of main circuit cables and copper bars, main circuit There are many cable connections, power devices are easily damaged, etc., to achieve the effect of simple layout, reduced volume and weight, and reduced peak voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

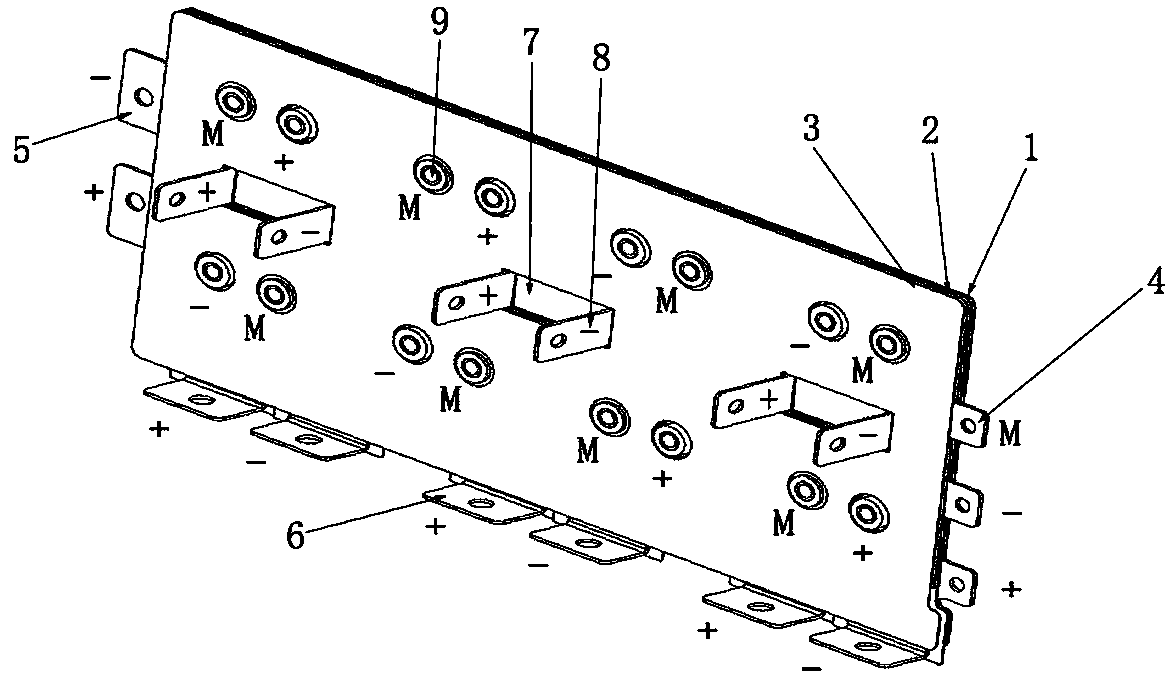

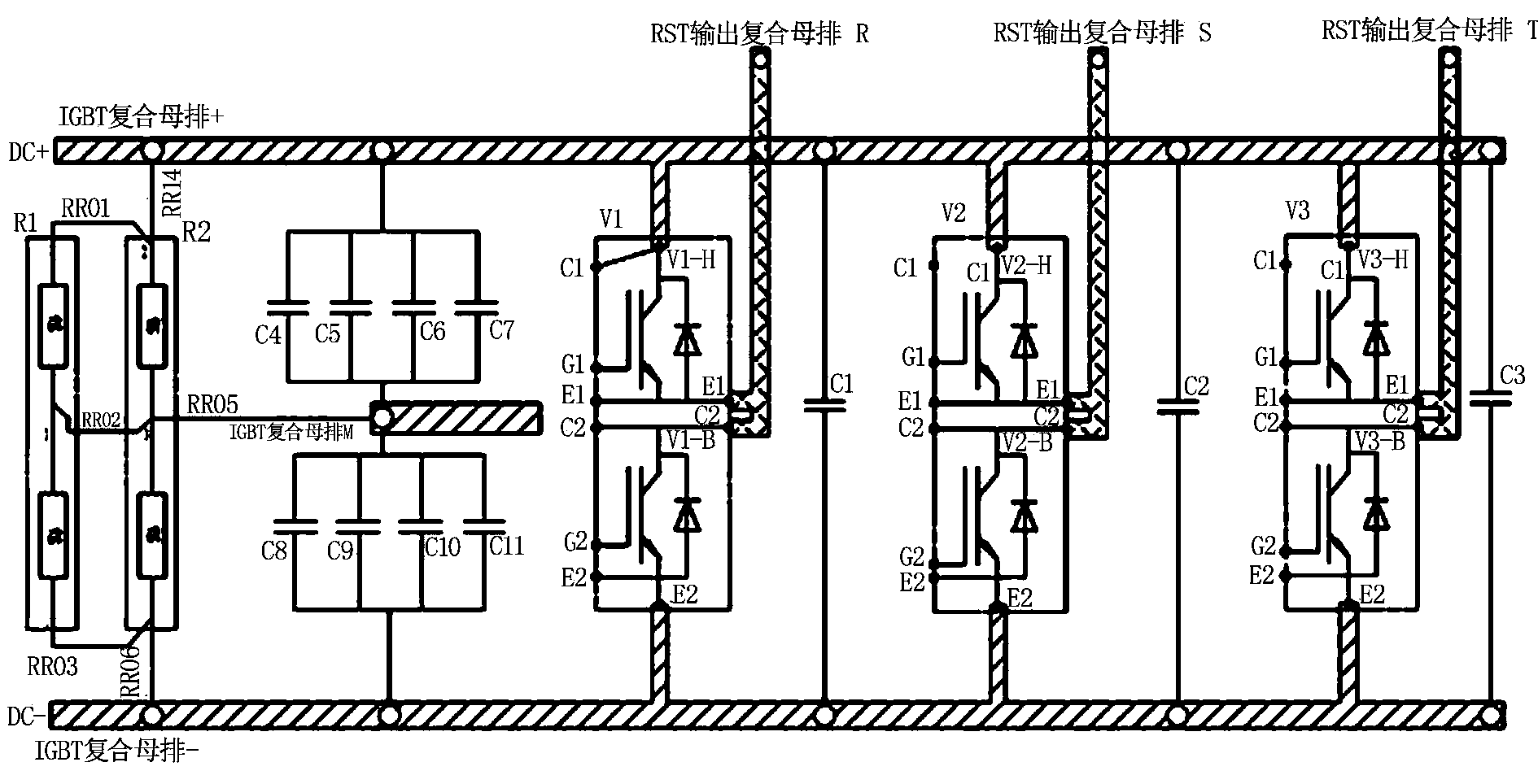

[0025] Such as figure 1 As shown, a three-phase inverter composite busbar suitable for half-bridge modules includes three flat busbars stacked together. The three busbars are positive busbar 1, Negative busbar 2 and M busbar 3, with high dielectric strength materials between adjacent busbars, such as high-voltage insulating polyester film; the right side of positive busbar 1, negative busbar 2 and M busbar 3 There is a discharge resistor connection part 4 on each side, and three discharge resistor connection parts 4 are arranged staggered up and down; the left side of the positive busbar 1 and the negative busbar 2 is respectively provided with an input terminal connection part 5, two The input terminal connection part 5 is arranged staggered up and down; three IGBT connection parts 6 are respectively provided on the bottom edge of the positive bus bar 1 and the negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com