Production technology and mixed emulsion device for improving stability of soldering flux for soldering paste

A production process and flux technology, applied in the field of production process and its mixing emulsification device, can solve the problems of uneven mixing of materials in flux, rosin sticking to the inner wall or bottom of the container, uneven product mixing, etc., to prevent volatilization loss Activity, improve performance stability, improve the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

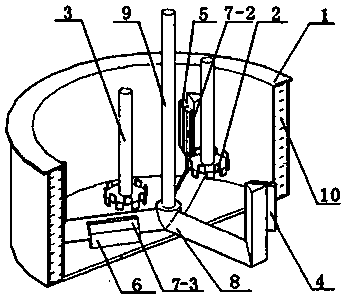

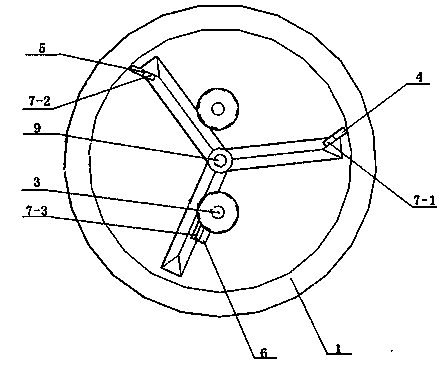

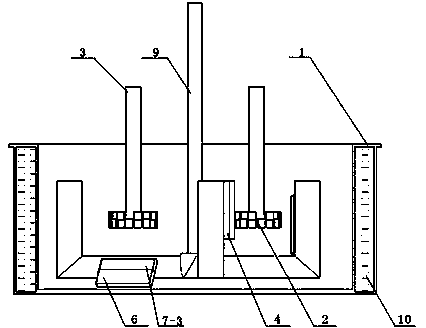

[0041] Add 3kg of tripropylene glycol monobutyl ether into barrel 1, and set the temperature to 110°C. When the temperature reaches the set value, add 4.6kg of hydrogenated rosin, start the impeller drive shaft 3, and set the emulsification and dispersion impeller 2 speed to 1500r / min, start the support drive shaft 9 at the same time, set the speed of scrapers 4, 5, and 6 to 50r / min, after the hydrogenated rosin is fully dissolved, set the temperature to 80°C, and add ten Hexaic acid 0.75kg, triethanolamine 0.2kg, keep the rotating speed of the emulsifying dispersing impeller 2 and scraper 4, 5, 6 unchanged, after fully mixing, set the temperature to 25°C, after the temperature drops to the set value, add nonyl Base phenol polyoxyethylene ether 0.7kg, hydrogenated castor oil 0.45kg, benzotriazole 0.3kg, vacuumize and maintain 1PSI vacuum degree, keep the speed of scraper 4, 5, 6 constant, reduce the speed of emulsification dispersion impeller 2 to 600r / min, after mixing evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com