Molybdenum disulfide/titanium dioxide compound and preparation method thereof

A molybdenum disulfide and titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, lubricating compositions, etc., can solve the problem of inability to obtain properties of molybdenum disulfide/titanium dioxide composites, insufficient mutual dispersion, and affecting the performance of the composites. and other problems, to achieve the effect of shortening the synthesis time, improving the dispersibility and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

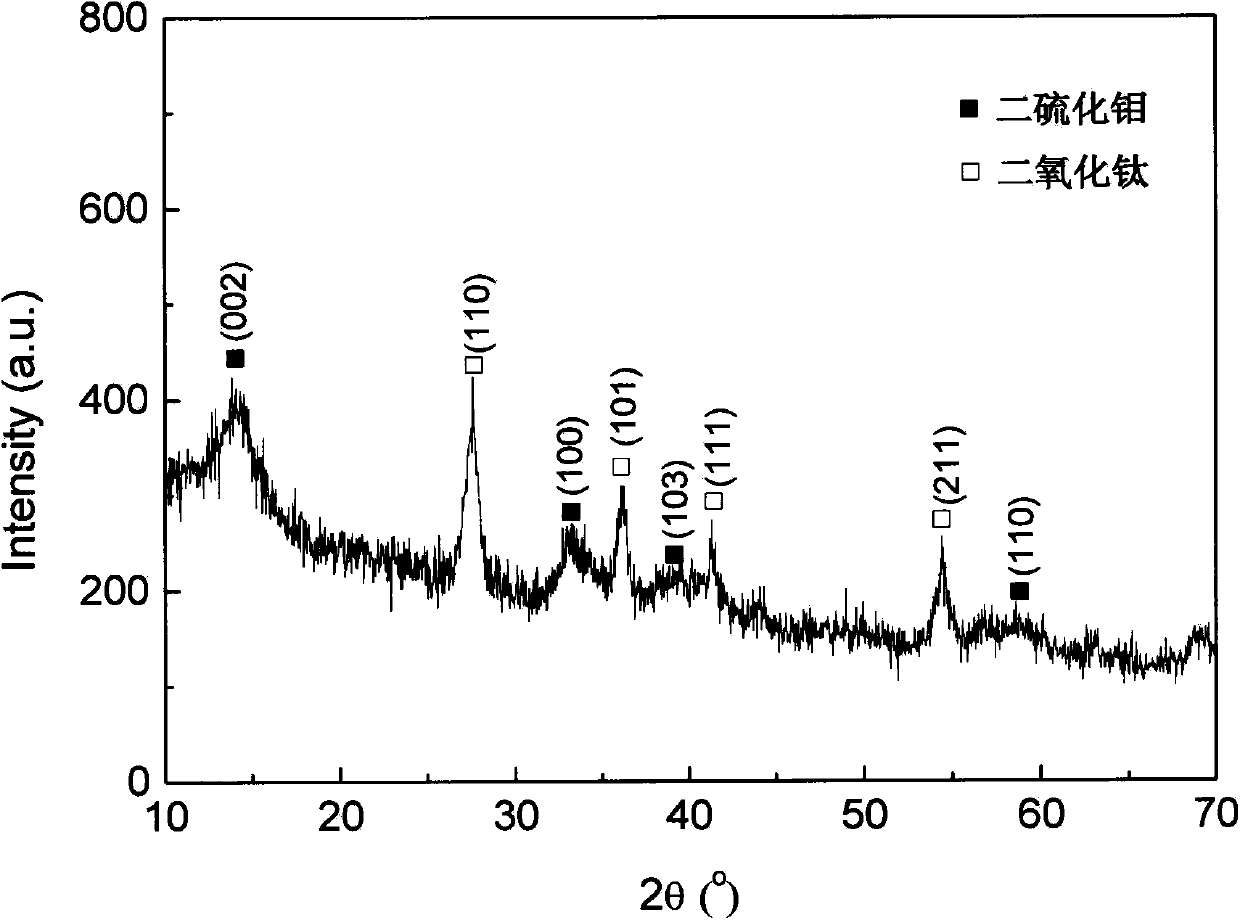

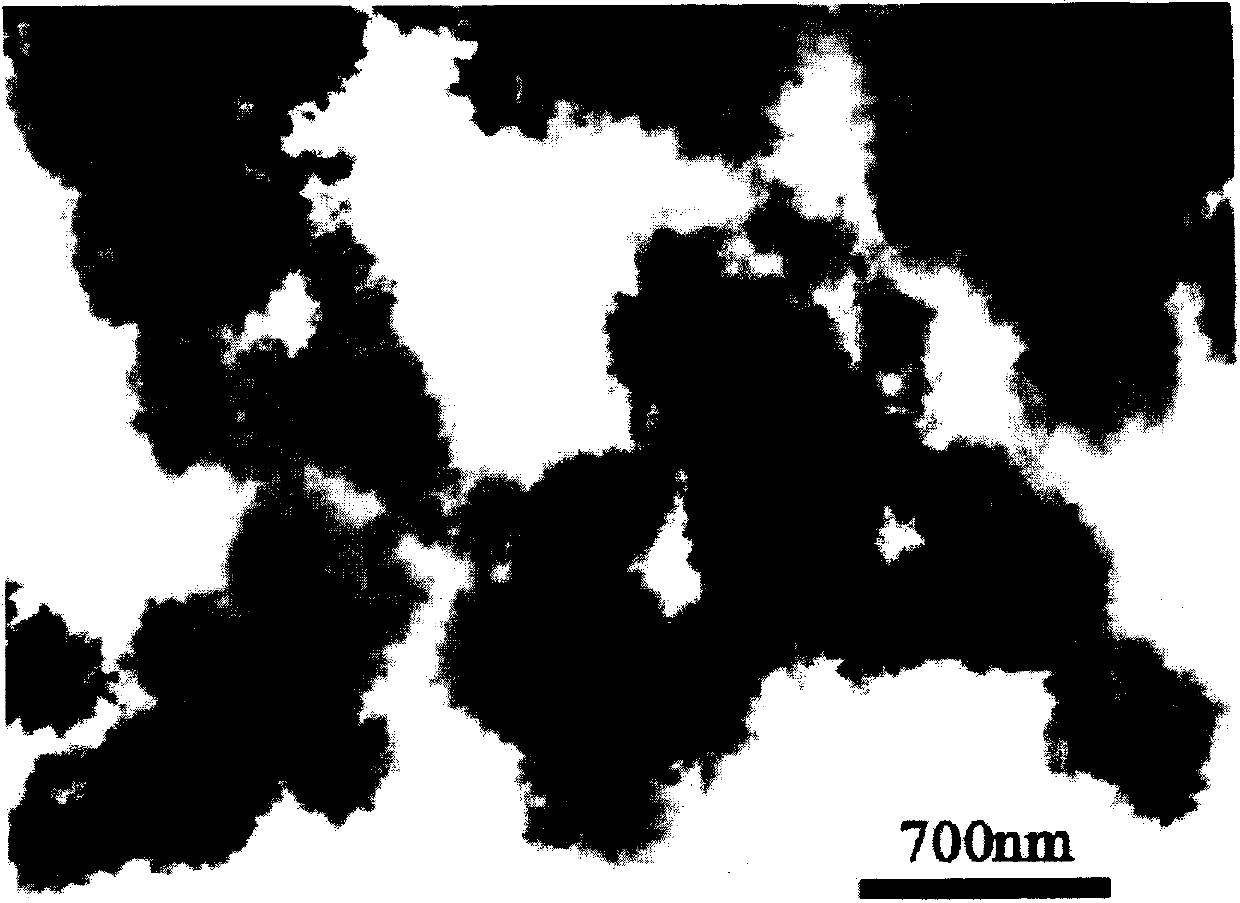

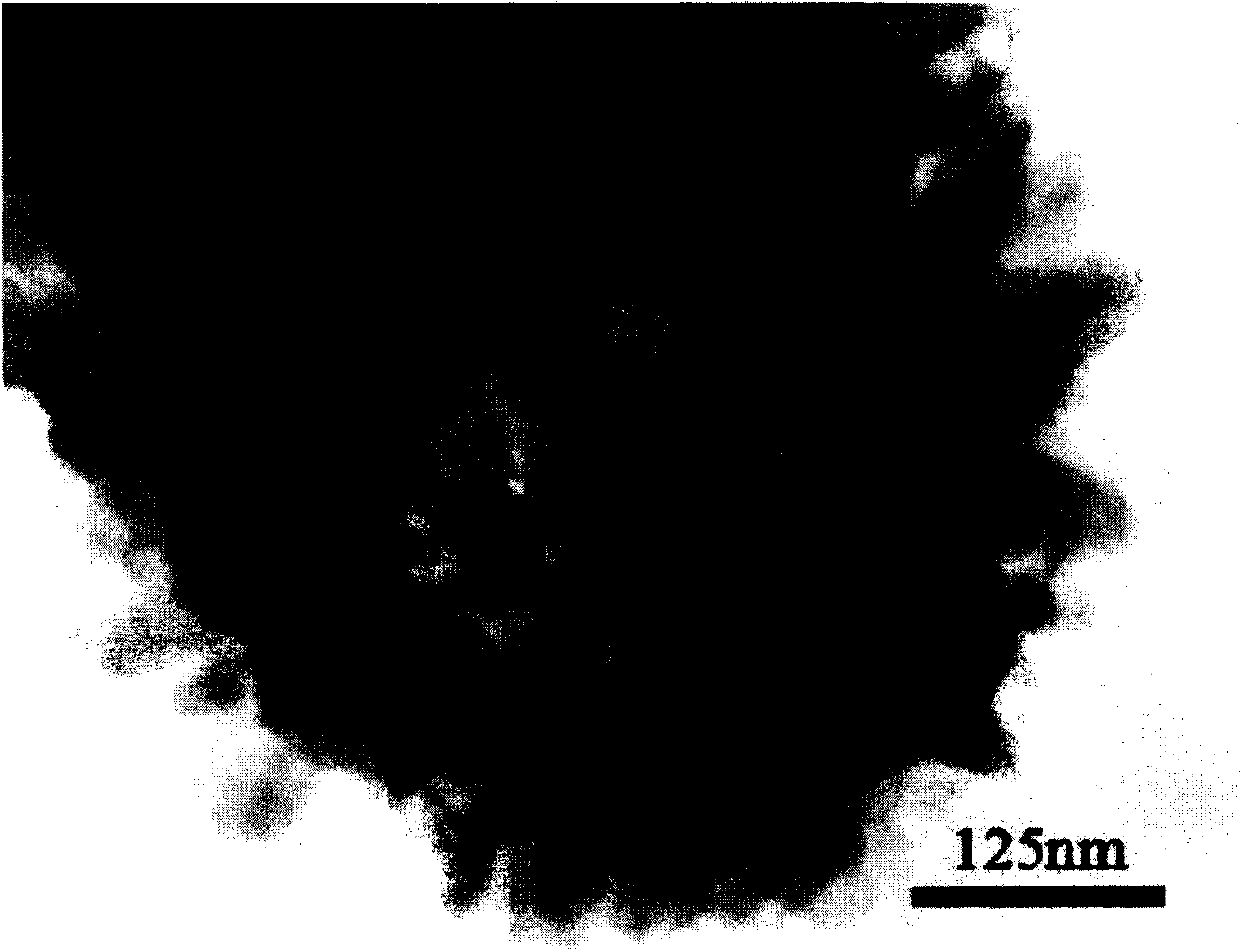

[0026] Dissolve 1 part of sodium molybdate and 6 parts of thioacetamide in 100 parts of water, heat the above solution to 80°C and keep it warm, then add 20 parts of titanium tetrachloride, the hydrochloric acid produced by the hydrolysis of titanium tetrachloride will cause thioacetamide Hydrolysis, the hydrogen sulfide produced by the hydrolysis of thioacetamide immediately reacts with sodium molybdate, and the reaction product forms a co-precipitation precursor with titanium dioxide produced by the hydrolysis of titanium tetrachloride. After the reaction, the co-precipitation precursor is filtered, washed and dried Calcined at 500°C for 50min in hydrogen, and cooled to room temperature to obtain a gray molybdenum disulfide / titanium dioxide composite (such as figure 1 Atlas and Figure 2-3 as shown in the photo).

Embodiment 2

[0028] Dissolve 1 part of sodium molybdate and 50 parts of thioacetamide in 2000 parts of water, heat the above solution to 100°C and keep it warm, then add 85 parts of titanium tetrachloride, the hydrochloric acid produced by the hydrolysis of titanium tetrachloride will cause thioacetamide Hydrolysis, the hydrogen sulfide produced by the hydrolysis of thioacetamide immediately reacts with sodium molybdate, and the reaction product forms a co-precipitation precursor with titanium dioxide produced by the hydrolysis of titanium tetrachloride. After the reaction, the co-precipitation precursor is filtered, washed and dried Calcined at 1000°C for 5min in nitrogen, and cooled to room temperature to obtain a gray molybdenum disulfide / titanium dioxide composite (approximately figure 1 Atlas and Figure 2-3 as shown in the photo).

Embodiment 3

[0030] Dissolve 1 part of sodium molybdate and 1 part of thioacetamide in 10 parts of water, heat the above solution to 60°C and keep it warm, then add 1 part of titanium tetrachloride, the hydrochloric acid produced by the hydrolysis of titanium tetrachloride will cause thioacetamide Hydrolysis, the hydrogen sulfide produced by the hydrolysis of thioacetamide immediately reacts with molybdate, and the reaction product forms a co-precipitation precursor with titanium dioxide produced by the hydrolysis of titanium tetrachloride. After the reaction, the co-precipitation precursor is filtered, washed and dried Calcined at 800°C for 40min in argon, and cooled to room temperature to obtain a gray molybdenum disulfide / titanium dioxide composite (approximately figure 1 Atlas and Figure 2-3 as shown in the photo).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com