A kind of naphtha reforming catalyst and preparation method thereof

A reforming catalyst and naphtha technology, which is applied in the direction of naphtha catalytic reforming, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy carbon deposition and deactivation, and achieve high isoparaffin selectivity, Good aromatization selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of catalyst provided by the invention comprises the steps:

[0031] (1) Mix mesoporous γ-alumina and pseudoboehmite evenly, extrude, dry, and roast to obtain a composite carrier,

[0032] (2) impregnating the composite carrier with an impregnating solution containing a platinum group metal compound and a group VIIB metal compound, the impregnating solution containing halogen, drying and calcining the impregnated carrier.

[0033] In the above method, the preparation of the mesoporous γ-alumina includes mixing the template agent and fatty alcohol, adding an acid and an aluminum source compound, under the condition of a pH value of 1 to 7, at 15 to 80°C, preferably at 20 to Fully react at 50°C, dry and bake at 800-900°C, the molar ratio of the aluminum source compound to the template agent is 1-200:1, preferably 10-100:1, and the molar ratio of the fatty alcohol to the aluminum source compound is 20 ~100:1, preferably 30~80:1, the volume ratio of f...

example 1

[0046] Preparation of mesoporous γ-alumina.

[0047] 60g (10.3mmol) P123 (EO 20 PO 70 EO 20 , with a molecular weight of 5800, produced by Aldrich, USA) was dissolved in 1100mL (19.5mol) of absolute ethanol, stirred vigorously for 2h to disperse the sol evenly, and then added 70mL of HNO with a concentration of 66.7% by mass to the homogeneously mixed colloidal solution 3 , stirred vigorously for 0.5h, added 120g (0.59mol) aluminum isopropoxide to it, the pH value was 5.6, reacted at 25°C for 8h under stirring, then dried the product at 60°C for 60h, and calcined at 800°C for 1h to obtain Al 2 o 3 , No. MA-800-1.

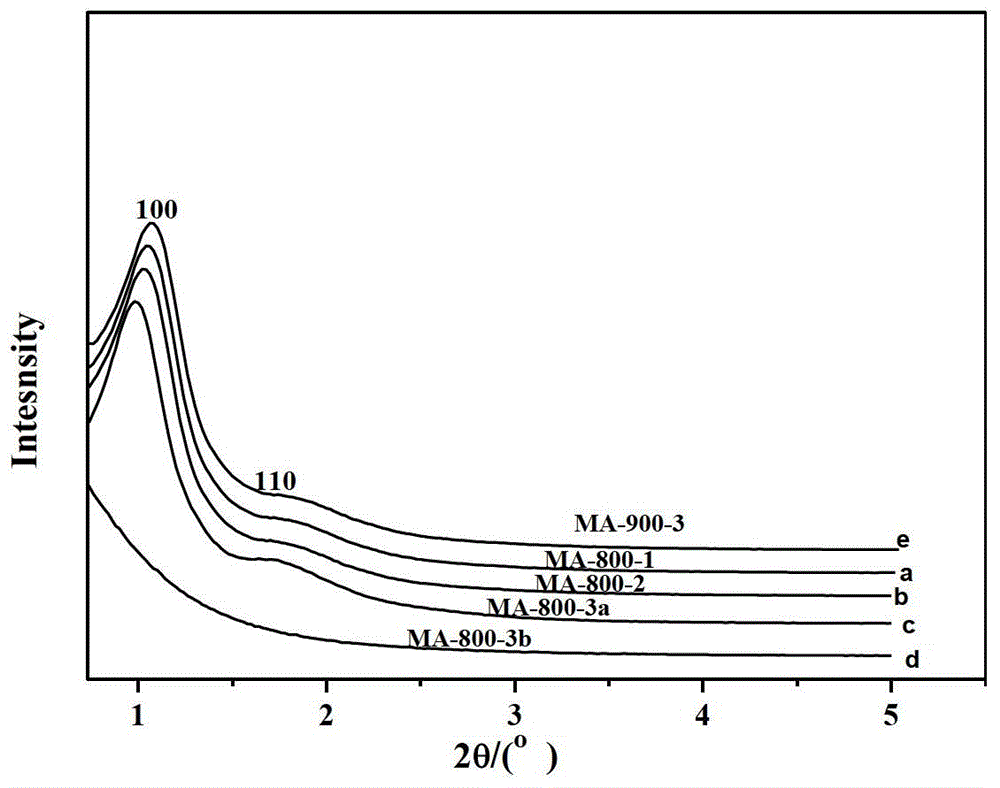

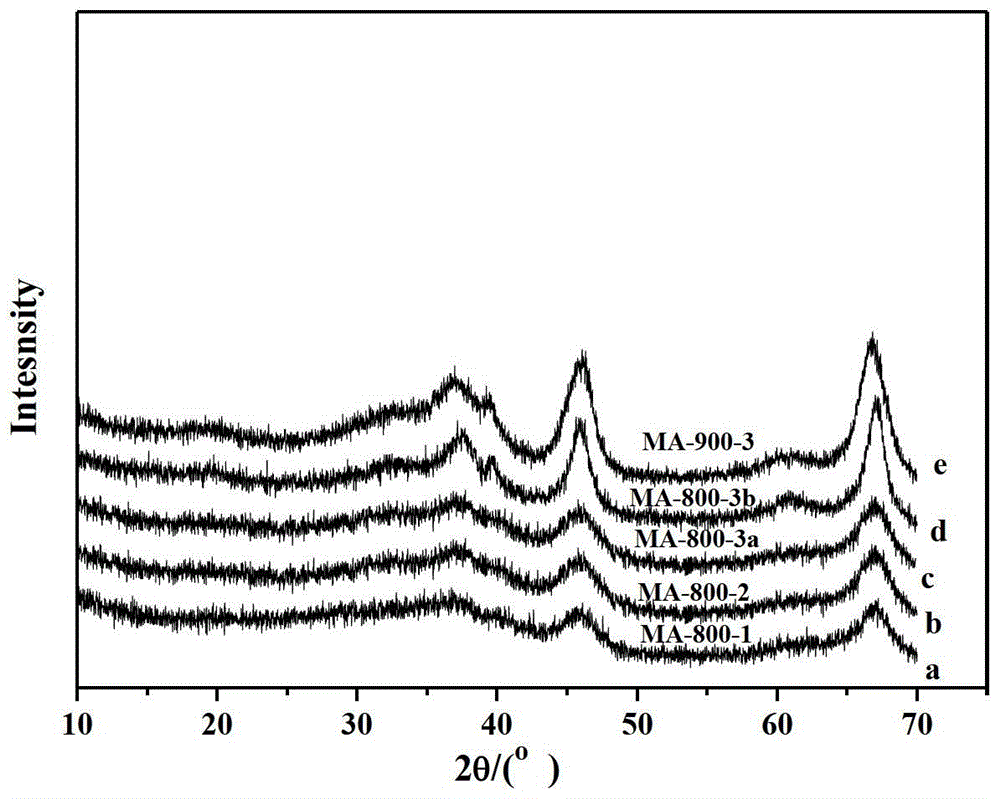

[0048] For the small angle XRD spectrum (0.5~5°) of MA-800-1 see figure 1 In the middle a curve, a sharp (100) surface characteristic diffraction peak appears in this curve, indicating the existence of mesopores. Wide-angle XRD spectrum (10-70°) such as figure 2 As shown in the middle a curve, the γ-Al 2 o 3 The characteristic diffraction peaks indicate th...

example 2

[0050] Dissolve 60g (10.3mmol) of P123 in 1000ml (10.9mol) of n-butanol, stir vigorously for 2h to disperse the sol evenly, then add 10.5gDL-malic acid and 70mL of 36.5 mass % hydrochloric acid, the molar ratio of HCl and malic acid is 11:1, stir vigorously for 0.5h, add 125.2g (0.33mol) aluminum nitrate, the pH value is 6.0, react at 25°C for 10h under stirring, and dry the product at 60°C 60h, calcined at 800°C for 1h to obtain Al 2 o 3 , No. MA-800-2.

[0051] For the small angle XRD spectrum (0.5~5°) of MA-800-2 see figure 1 In the b curve, a sharp (100) plane diffraction peak appears, and the wide-angle XRD spectrum is as follows figure 2 As shown in the b curve, there is also γ-Al 2 o 3 The characteristic diffraction peaks indicate that it is mesoporous γ-Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com