Carbon fiber and glass fiber mixed type plane grating rib

A glass fiber and alkali-free glass fiber technology, which is applied in the field of reinforcing materials for concrete structures, can solve the problems of insufficient cohesion of the bonding interface and needs to be improved, and achieves strong designability, extended service life and good stability. Effect

Inactive Publication Date: 2014-12-03

CHANGZHOU HUIYUN COMPOSITE MATERIALS

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the tensile strength and elastic modulus of the sheet still need to be improved, and there are still technical deficiencies in the cohesiveness of the bonding interface.

Moreover, especially in harsh environments such as marine corrosion, the bearing capacity needs to be improved, and the durability, safety and impact resistance of the structure need to be improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

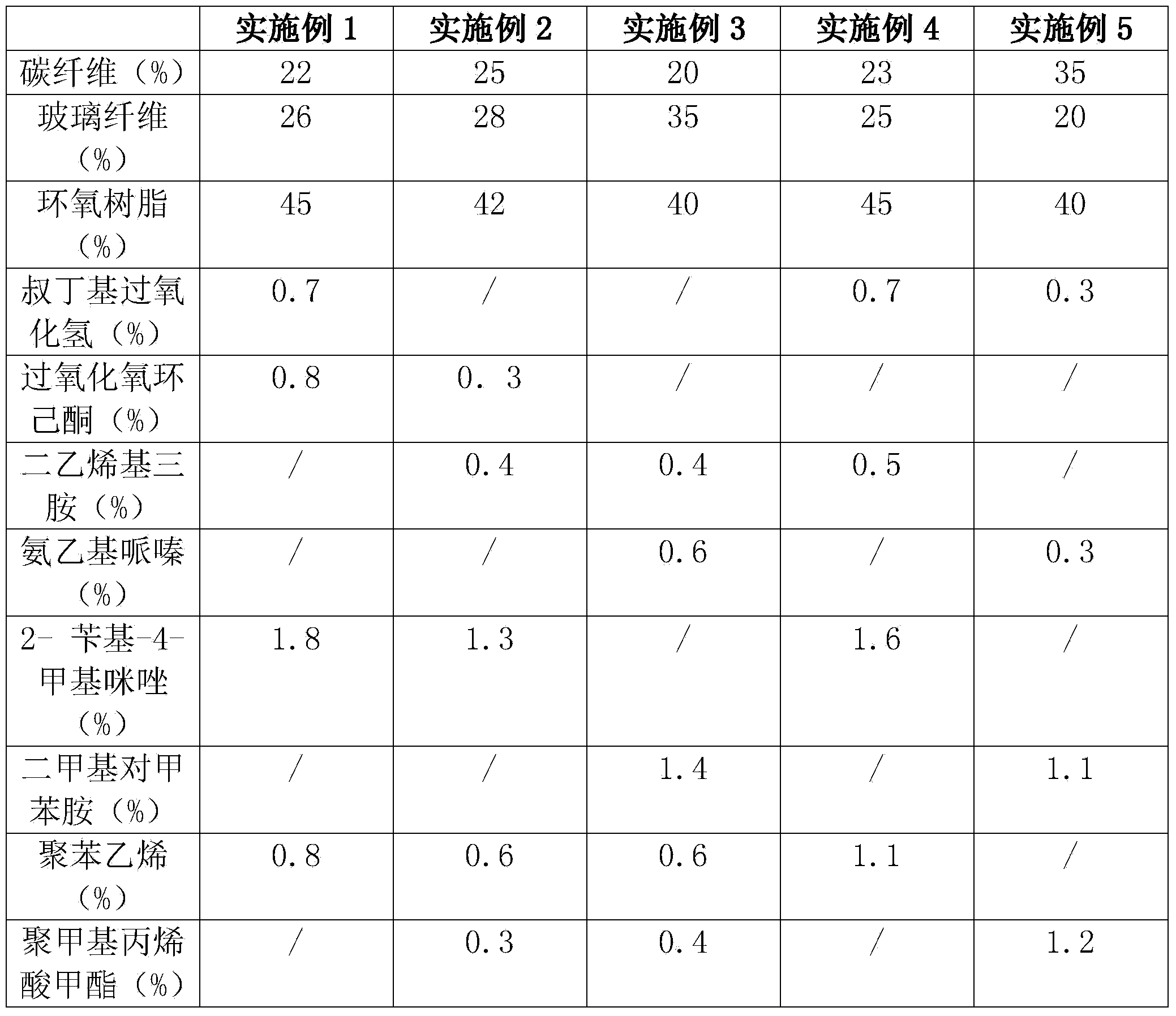

[0039] Embodiment 3 is a preferred embodiment of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

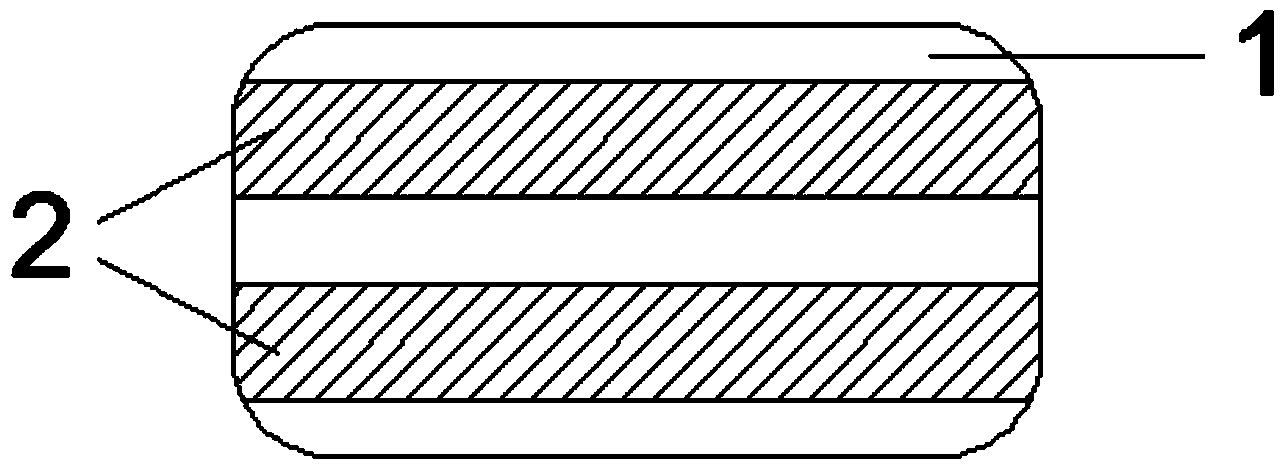

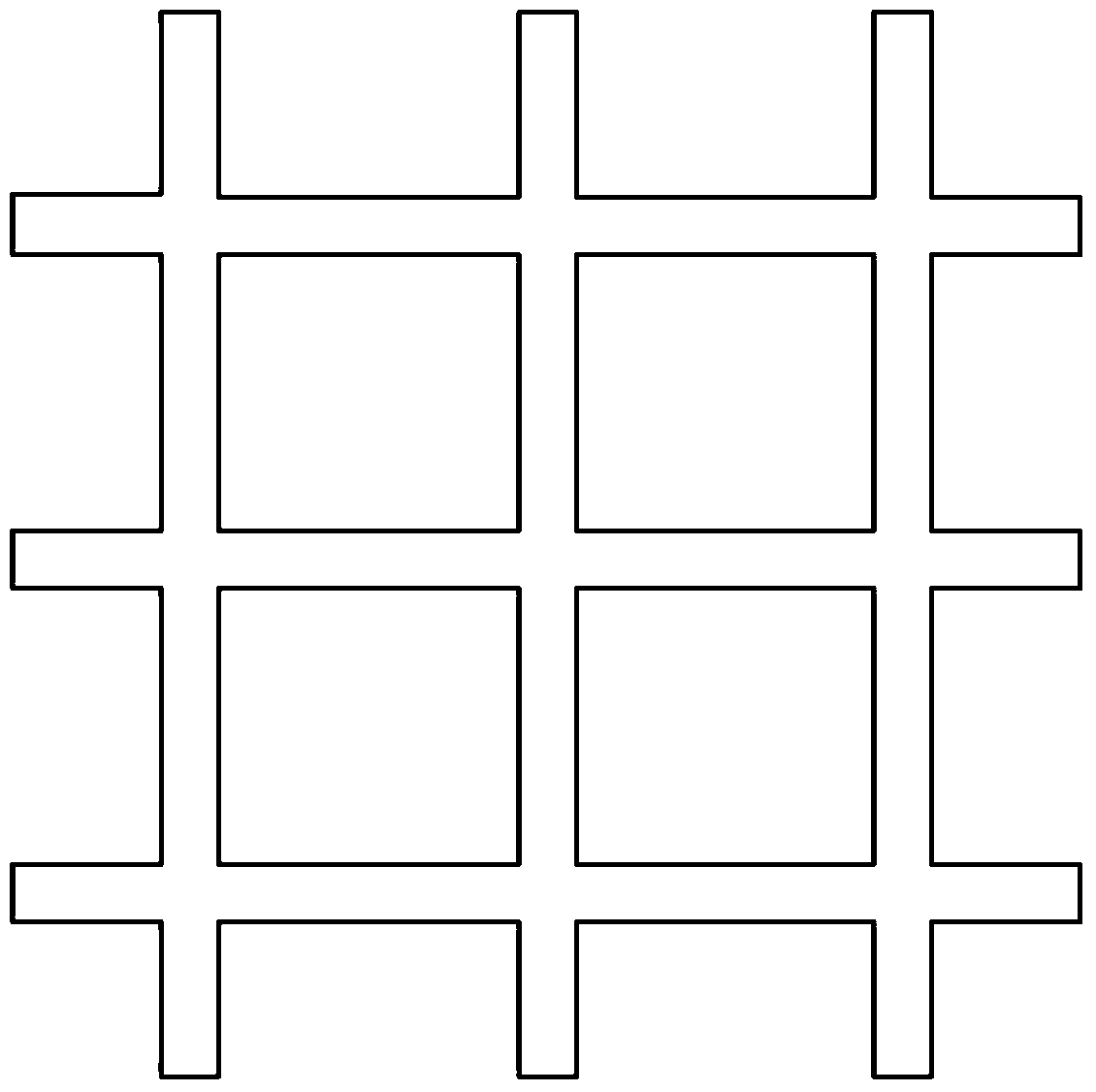

The invention relates to the technical field of reinforcing materials of concrete structures and in particular relates to a carbon fiber and glass fiber mixed type plane grating rib comprising three carbon fiber bundle layers, wherein alkali-free glass fiber bundle layers are arranged among the three carbon fiber bundle layers. The carbon fiber and glass fiber mixed type plane grating rib comprises the following components in percentage by volume: 20%-35% of carbon fiber, 20%-35% of glass fiber, 40%-45% of epoxy resin, 0.6%-1.5% of curing agent, 1.1%-1.8% of accelerant, 0.8%-1.2% of low shrinkage agent, 0.6%-1.1% of release agent, 0.8%-1.6% of fire retardant, 0.2%-0.8% of antistatic agent and the balance being padding. According to the carbon fiber and glass fiber mixed type plane grating rib, elastic modulus is close to 145GPa, limiting strain achieves 3.5% and is about 2 times that of a common GFRP rib, damping property is good, fatigue resistance is good, and bond durability with concrete is good. The carbon fiber and glass fiber mixed type plane grating rib is widely applied to concrete marine environment structural engineering field and can be used as substitute for a rebar, the service life is prolonged, and designability is strong.

Description

technical field [0001] The invention relates to the technical field of reinforcement materials for concrete structures, in particular to a carbon fiber glass fiber mixed plane grid bar. Background technique [0002] In concrete construction engineering, reinforced concrete structures are widely used. This structure makes full use of the compressive properties of concrete and the tensile properties of steel bars, and has been widely used in the field of construction engineering for a long time. But as time went on, the disadvantages of this structure became more and more obvious. Due to various reasons, cracks often occur in reinforced concrete. When the cracks spread to the steel bars, the steel bars will corrode. This phenomenon is more obvious especially in the severe cold regions of the north, in environments where a large amount of ice-melting salt is used, and in coastal areas. Corrosion and rusting of steel bars affect the durability of reinforced concrete structure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B17/04B32B17/06B32B17/12C08L63/00C08J5/04C08K13/04C08K7/14C08K7/06C08K5/14C08K5/3445C08K3/34

Inventor 方海黄宝宝杨杰

Owner CHANGZHOU HUIYUN COMPOSITE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com