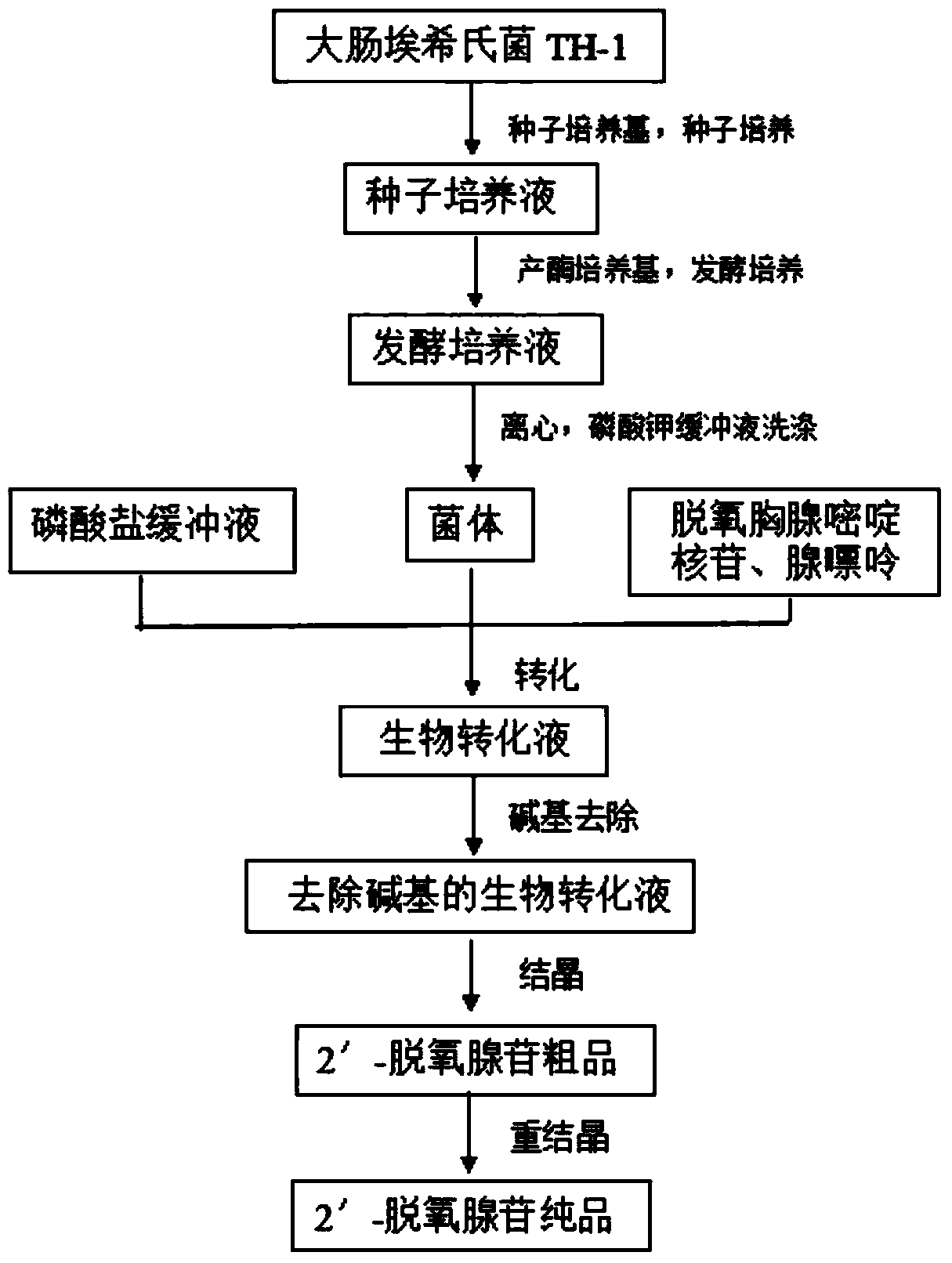

Method for converting escherichia coli to produce 2'-deoxyadenosine

A technology of Escherichia coli and deoxyadenosine, applied in the field of bioengineering, can solve the problems of complex steps, high cost, and low conversion rate, and achieve the effect of mild reaction conditions, low production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Seed culture

[0046] Take a ring of activated Escherichia coli strains with high nucleoside phosphorylase activity, inoculate them in a 500ml Erlenmeyer flask, and cultivate them on a shaker at 37°C for 28 hours. The seed medium consists of: 5.2g of yeast extract, Peptone 11.5g, NaCl 5.5g and distilled water 1000mL, sterilized at 121°C for 20min, pH value 7.0.

[0047] 2) Fermentation culture and cell preparation

[0048] Use 12L enzyme-producing medium in a 20L automatic fermentation tank, inoculate Escherichia coli seed culture solution according to the inoculum volume of 6% of the volume of the enzyme-producing medium, cultivate at 37°C for 8h, and then centrifuge at 6000rpm for 8min at 4°C , to obtain the Escherichia coli wet thalline, the gained wet thalline is 7.0 with the pH value, the concentration is the potassium phosphate buffer solution washing 2 times of 20mmol / L, centrifugation obtains the required Escherichia coli thalline, in- Store frozen at 20°C ...

Embodiment 2

[0058] 1) Seed culture

[0059] Take a loop of activated Escherichia coli strains with high nucleoside phosphorylase activity, inoculate them in a 500ml Erlenmeyer flask, and culture them on a shaker at 37°C for 36 hours. The seed medium consists of: 6g of yeast extract, peptone 12.5g, NaCl7.5g and distilled water 1000mL, sterilized at 121°C for 20min, pH value 7.2.

[0060] 2) Fermentation culture and cell preparation

[0061] Use 12L enzyme-producing medium in a 20L automatic fermentation tank, inoculate the Escherichia coli seed culture solution according to the inoculum volume of 6% of the volume of the enzyme-producing medium, incubate at 37°C for 9h, and then centrifuge at 5000rpm for 10min at 4°C , to obtain the Escherichia coli wet thalline, the gained wet thalline is 7.0 with the pH value, and concentration is the potassium phosphate buffer solution washing 3 times of 20mmol / L, centrifugation obtains the required Escherichia coli thalline, in- Store frozen at 20°C f...

Embodiment 3

[0071] 1) Seed culture

[0072] Take a ring of activated Escherichia coli strains with high nucleoside phosphorylase activity, inoculate them in a 500ml Erlenmeyer flask, and cultivate them on a shaker at 37°C for 40 hours. The seed medium consists of: 8.2g of yeast extract, Peptone 14.1g, NaCl 7.3g and distilled water 1000mL, sterilized at 121°C for 20min, pH value 7.3.

[0073] 2) Fermentation culture and cell preparation

[0074] Use 12L enzyme-producing medium in a 20L automatic fermentation tank, inoculate Escherichia coli seed culture solution according to the inoculum volume of 7% of the volume of the enzyme-producing medium, cultivate at 37°C for 10h, and then centrifuge at 8000rpm at 4°C for 7min , to obtain the Escherichia coli wet thalline, the gained wet thalline is 7.0 with the pH value, the concentration is the potassium phosphate buffer solution washing 2 times of 20mmol / L, centrifugation obtains the required Escherichia coli thalline, in- Store frozen at 20°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com