Biogenic synergistic compound herbicide containing n-nonanoic acid and preparation method thereof

A technology of biological sources and herbicides, applied in botany equipment and methods, biocides, herbicides and algicides, etc., can solve problems such as residual poisons and phytotoxicity, yield reduction of next crops, emergence of weed resistance, etc. Achieving good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

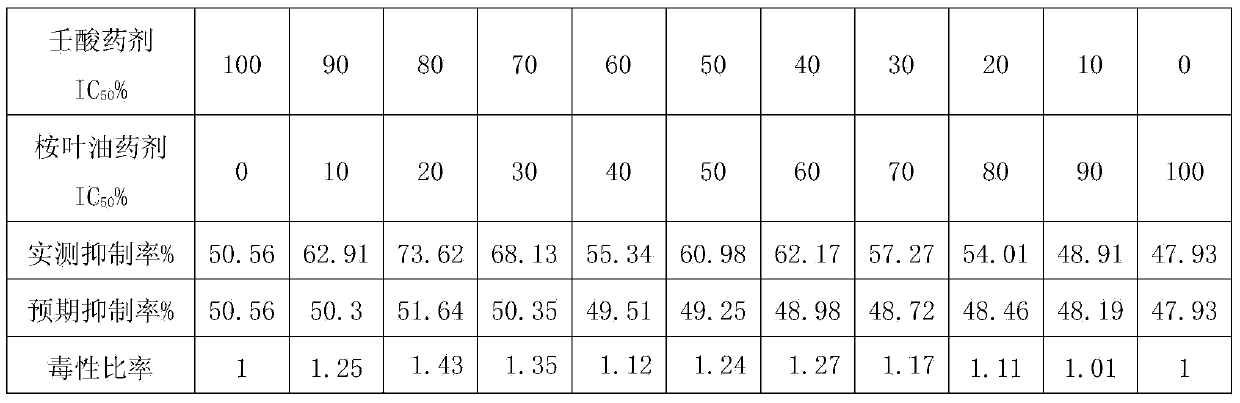

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Preparation of 50% eucalyptus oil nonanoic acid emulsifiable concentrate

[0051] The 50% described in this embodiment is a mass percentage, and the eucalyptus oil nonanoic acid emulsifiable concentrate means the emulsifiable concentrate obtained by compounding eucalyptus oil and pelargonic acid;

[0052] At 20-25°C, take 50 parts of eucalyptus oil and nonanoic acid mixture, the mixing ratio of eucalyptus oil and nonanoic acid is 1:4, add 10 parts of azone and 20 parts of white oil sequentially on the basis of the above mixture, 3 parts of sodium dodecylbenzene sulfonate and 7 parts of octylphenol polyoxyethylene ether, 100% of methyl oleate, stirring at a stirring speed of 200-500 rpm for 10-30 minutes, can be prepared 50 % Eucalyptus Oil · Nonanoic Acid Eco-friendly EC.

Embodiment 2

[0053] Embodiment 2: 40% eucalyptus oil·nonanoic acid water emulsion preparation

[0054] The 40% described in this embodiment is a mass percentage, and the eucalyptus oil-nonanoic acid water emulsion means the water emulsion obtained by compounding eucalyptus oil and nonanoic acid;

[0055] At 20-25°C, take 40 parts of a mixture of eucalyptus oil and nonanoic acid, the compounding ratio of eucalyptus oil and nonanoic acid is 3:7, and add 2 parts of azone and styryl block to the above mixture in sequence 5 parts of polyether, 3 parts of octylphenol polyoxyethylene ether phosphate, 5 parts of ethylene glycol, after mixing evenly, add 100 parts of aqueous solution containing 0.05% xanthan gum to make up 100 parts, and the speed of high-speed shearing machine is 8000 rpm Stir for 20 to 30 minutes to prepare 40% eucalyptus oil·nonanoic acid aqueous emulsion.

Embodiment 3

[0056] Embodiment 3: 30% eucalyptus oil·nonanoic acid microemulsion preparation

[0057] The 30% described in this embodiment is a mass percentage, and the eucalyptus oil-nonanoic acid microemulsion represents the microemulsion obtained by compounding eucalyptus oil and nonanoic acid;

[0058] At 20-25°C, take 30 parts of a mixture of eucalyptus oil and nonanoic acid, the compounding ratio of eucalyptus oil and nonanoic acid is 2.5:7.5, then add 5 parts of azone and 13 parts of dodecane to the above mixture in sequence Calcium phenylbenzenesulfonate, 2 parts of styrene phenol polyoxyethylene (n30) ether, 2 parts of nonylphenol polyoxyethylene ether, 5 parts of ethylene glycol, after mixing evenly, make up 100 parts of water, at a stirring speed of 800-1000 30% eucalyptus oil·nonanoic acid microemulsion can be prepared by stirring for 20 to 30 minutes at rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com