A double-layer composite biological dressing and its adhesive-free composite process

A biological dressing, double-layer composite technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of increased components and harm, and achieve the effects of fast water absorption, good comfort, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

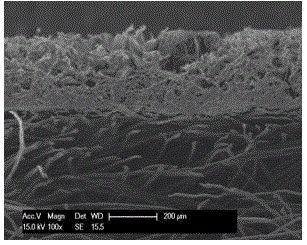

Image

Examples

Embodiment 1

[0031] Divide 20*20cm 2 100g / m 2 The chitosan fiber needle-punched non-woven fabric was laid flat on a stainless steel freezing tray, sprayed 30ml of RO pure water on the surface of the non-woven fabric, placed in an ultra-low temperature refrigerator, and pre-frozen at -40°C for 30 minutes; the sponge layer material solution was prepared with a total concentration of 3.5 wt%, weigh 1.1g of macromolecular chitosan, 0.3g of small molecular chitosan, 1.1g of macromolecular collagen, and 0.3g of small molecular collagen, dissolve in 80ml of 0.5wt% acetic acid aqueous solution, and homogenize at room temperature Stir with machine until uniform, ultrasonic degassing, and store at 20°C; take out the pre-frozen chitosan non-woven fabric freezing plate, and quickly spray the sponge layer raw material solution on the non-woven fabric evenly, with a spray volume of 40ml / 20*20cm 2 , and the operation time is less than 5 minutes; then put it into an ultra-low temperature refrigerator, fr...

Embodiment 2

[0035] Divide 20*20cm 2 100g / m 2The chitosan fiber needle-punched non-woven fabric was laid flat on a stainless steel freezing tray, sprayed 40ml RO pure water on the surface of the non-woven fabric, placed in an ultra-low temperature refrigerator, and pre-frozen at -40°C for 30 minutes; the sponge layer material solution was prepared with a total concentration of 2.5 wt%, weigh 0.8 g of macromolecular chitosan, 0.2 g of small molecular chitosan, 0.8 g of macromolecular collagen, and 0.2 g of small molecular collagen, dissolve them in 80 ml of 0.5 wt % acetic acid aqueous solution, and homogenize at room temperature Stir to a uniform state, ultrasonically degas, and store at 20°C; take out the pre-frozen chitosan non-woven fabric freezing plate, and quickly spray the sponge layer raw material solution evenly on the non-woven fabric, the spray volume is 60ml / 20*20cm 2 , and the operation time is less than 5 minutes; then put it into an ultra-low temperature refrigerator, freez...

Embodiment 3

[0039] Divide 20*20cm 2 100g / m 2 The chitosan fiber needle-punched non-woven fabric was laid flat on a stainless steel freezing tray, sprayed with 30ml RO pure water on the surface of the non-woven fabric, placed in an ultra-low temperature refrigerator, and pre-frozen at -30°C for 30 minutes; the sponge layer material solution was prepared with a total concentration of 2.0 wt%, weigh 0.8g of macromolecular chitosan, 0.2g of small molecular chitosan, 0.8g of macromolecular collagen, and 0.2g of small molecular collagen, dissolve in 100ml of 0.5% acetic acid aqueous solution, and homogenize at room temperature Stir with machine until uniform, degas with ultrasonic, store at 20°C; take out the pre-frozen chitosan non-woven fabric freezing plate, quickly spray the sponge layer raw material solution on the non-woven fabric evenly, the spray volume is 50ml / 20*20cm 2 , the operation time is less than 5 minutes; then put it into a low-temperature refrigerator, freeze at -40°C for 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com