Device for preparing hydrogen gas by decomposing water through synergic action of oxygen-permeable membrane and hydrogen-permeable membrane

A technology of hydrogen permeable membrane and oxygen permeable membrane, which is applied in the hydrogen permeable membrane synergistic decomposition of water to produce hydrogen, and in the field of oxygen permeable membrane, which can solve the problems of limited water pyrolysis, reduced conversion rate, and oxidative damage of hydrogen permeable membrane. , to avoid carbon monoxide residue, reduce stress and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

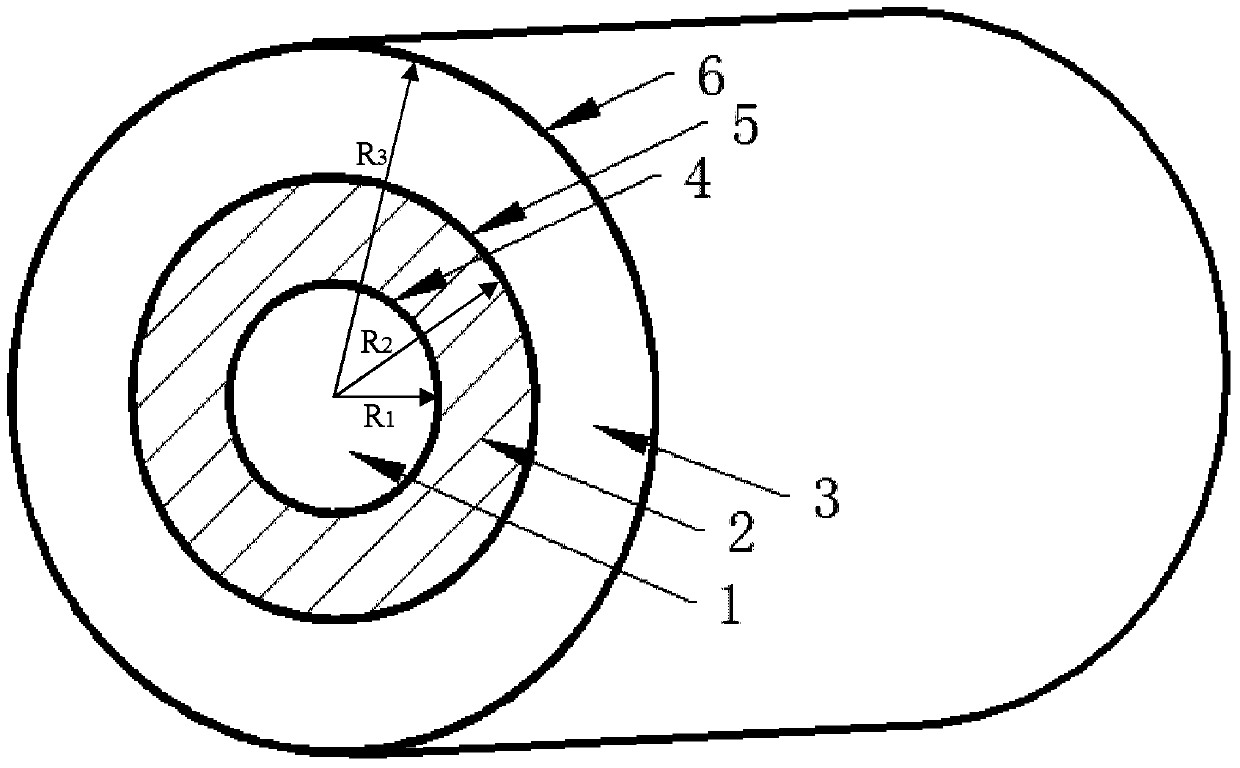

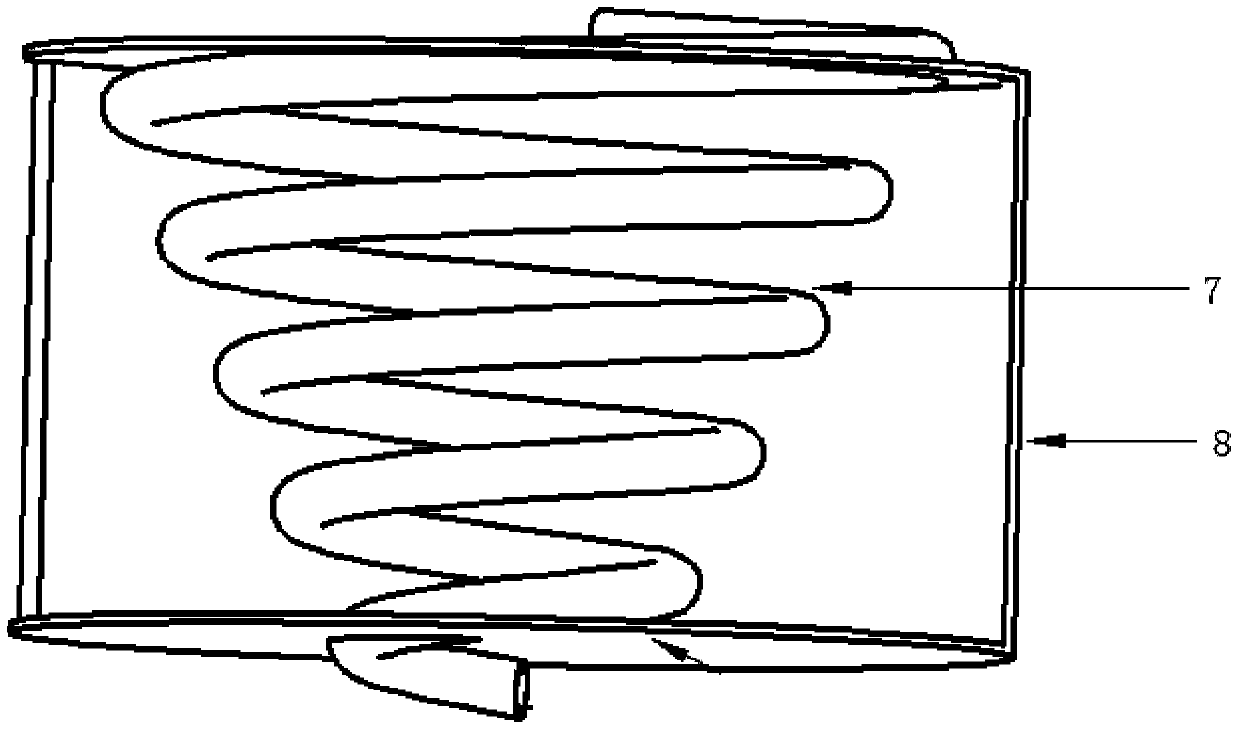

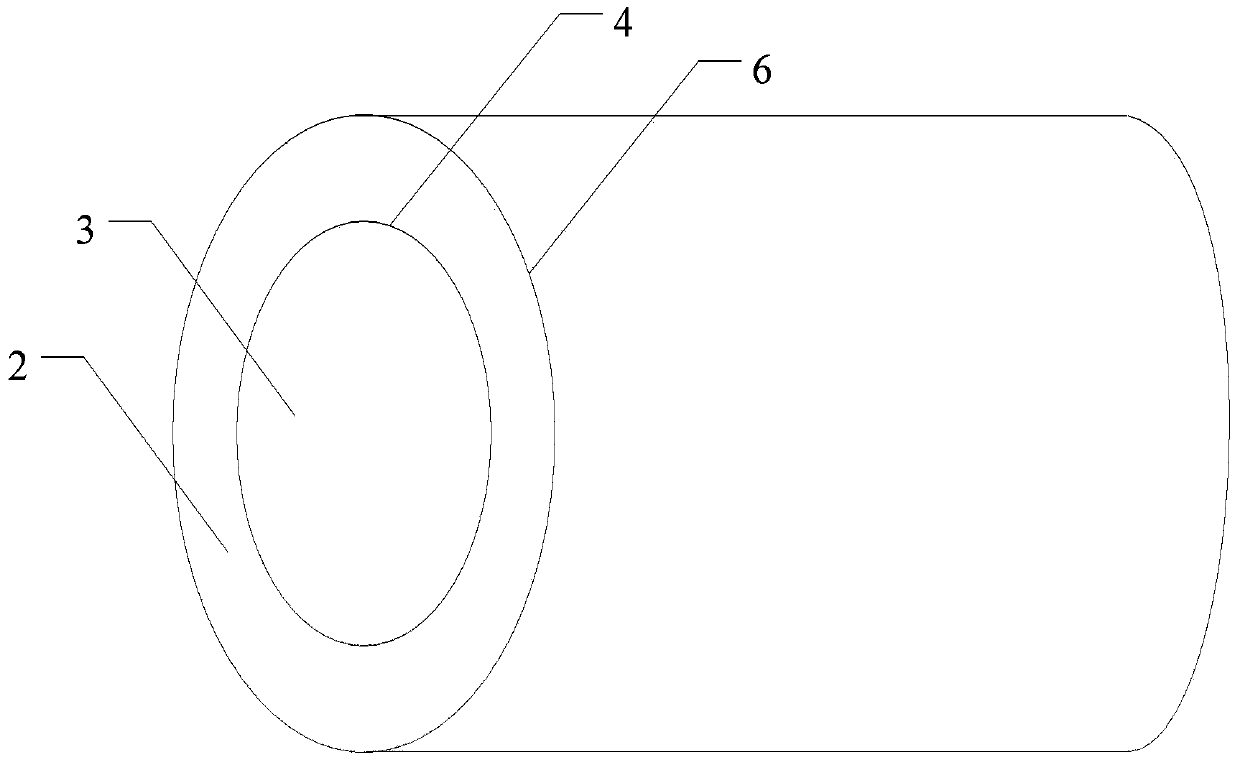

[0028] In the first exemplary embodiment of the present invention, an oxygen-permeable membrane and a hydrogen-permeable membrane synergistically decompose water to produce hydrogen gas. figure 1 It is a schematic structural diagram of a three-layer casing structure in a device for producing hydrogen by coordinating water splitting with an oxygen-permeable membrane and a hydrogen-permeable membrane according to the first embodiment of the present invention.

[0029] Please refer to figure 1 In this embodiment, the oxygen-permeable membrane and the hydrogen-permeable membrane synergistically decompose water to produce hydrogen, including: a reaction chamber, which is used to provide the working temperature required for the reaction; a three-layer casing structure, located in the reaction chamber, which forms a steam chamber in the middle Chamber 2 and the oxygen-permeable chamber 3 and hydrogen-permeable chamber 1 on both sides of the steam chamber, the oxygen-permeable chamber...

no. 3 example

[0053] In the third exemplary embodiment of the present invention, another device for synergistically decomposing water to produce hydrogen by an oxygen-permeable membrane and a hydrogen-permeable membrane is provided. The device differs from the above two embodiments in that both the oxygen-permeable membrane and the hydrogen-permeable membrane are non-metallic membranes.

[0054] By applying a potential difference between the oxygen permeable chamber 1 and the steam chamber, the potential of the oxygen permeable chamber 1 is higher than that of the steam chamber 2 . At the same time, the potential of the hydrogen permeable chamber 1 is lower than that of the steam chamber 2 by applying a potential difference between the hydrogen permeable chamber 1 and the steam chamber. In general, the absolute value of the potential difference △V satisfies: 0V<△V≤500V.

[0055] It should be clear to those skilled in the art that the potential difference method can only be used if the oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com