Method for preparing mesoporous hydroxyapatite nanometer particle with high specific surface area by virtue of template method

A technology of mesoporous hydroxyapatite and high specific surface area, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of uneven pore size distribution and small surface area, and achieve drug loading The effect of large amount, large specific surface area and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

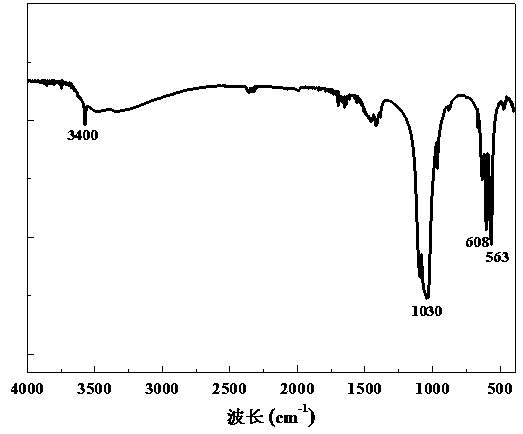

Image

Examples

Embodiment 1

[0028] The preparation method of the mesoporous hydroxyapatite nanoparticles provided in this embodiment is carried out in the following steps:

[0029] 1. Dissolve 2.68g of F127 and 17.67g of calcium pantothenate monohydrate in 100g of deionized water, stir vigorously for 2 hours to obtain a clear emulsion; add 12ml of mesitylene solution to the above mixed solution, and stir while adding After the dropwise addition, the mixed solution was stirred for 6 hours.

[0030] Two, the 5.52g K 2 HPO 4 ·3H 2 O was dissolved in 66g of deionized water, stirred and dissolved, and NH 3 ·H 2 O adjusts the pH to 11.

[0031] 3. Use a separatory funnel to mix 0.35mol / L of K 2 HPO 4 The solution was slowly added dropwise into the mixed solution of F127-calcium pantothenate monohydrate, and stirred evenly. After the dropwise addition, the mixed solution was heated to 90° C. in a water bath, and refluxed for 24 hours.

[0032] 4. After the above-mentioned reacted solution is cooled,...

Embodiment 2

[0041] The preparation method of the mesoporous hydroxyapatite nanoparticles provided in this embodiment is carried out in the following steps:

[0042] 1. Dissolve 3.35g of F127 and 22.43g of calcium pantothenate monohydrate in 200g of deionized water, stir vigorously for 3 hours to obtain a clear emulsion; add 16ml of mesitylene solution to the above mixed solution, and stir while adding After the dropwise addition, the mixed solution was stirred for 8 hours.

[0043] Two, the 7.13g K 2 HPO 4 ·3H 2 O was dissolved in 130 g of deionized water, stirred magnetically, and then dissolved with NH 3 ·H 2 O adjusts the pH to 13.

[0044] 3. Use a separatory funnel to mix 0.30mol / L of K 2 HPO 4 The solution was slowly added dropwise to the mixed solution of F127-calcium pantothenate monohydrate, and stirred evenly. After the dropwise addition, the mixed solution was heated to 95° C. in a water bath and refluxed for 28 hours.

[0045] 4. Suction filter the above-mentioned re...

Embodiment 3

[0049] The preparation method of the mesoporous hydroxyapatite nanoparticles provided in this embodiment is carried out in the following steps:

[0050] 1. Dissolve 3.92g of F127 and 26.62g of calcium pantothenate monohydrate in 250g of deionized water and stir vigorously for 4 hours to obtain a clear emulsion; add 22ml of mesitylene solution to the above mixed solution and stir while adding After the dropwise addition, the mixed solution was stirred for 10 hours.

[0051] Two, the 11.26g K 2 HPO 4 ·3H 2 O was dissolved in 130 g of deionized water, stirred magnetically, and then dissolved with NH 3 ·H 2 O adjusts the pH to 12.

[0052] 3. Use a separatory funnel to mix 0.38mol / L of K 2 HPO 4 The solution was slowly added dropwise into the mixed solution of F127-calcium pantothenate monohydrate, and stirred evenly. After the dropwise addition, the mixed solution was heated to 98° C. in a water bath, and refluxed for 32 hours.

[0053] 4. After the above-mentioned re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com