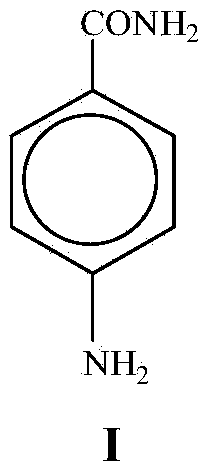

Preparation method for p-aminobenzamide

A technology of aminobenzamide and nitrobenzamide, which is applied in the field of preparation of p-aminobenzamide, can solve the problems of high production cost, inability to apply waste water, backward technology, etc., and achieve product quality and yield improvement, discharge Effects of reduced waste water and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

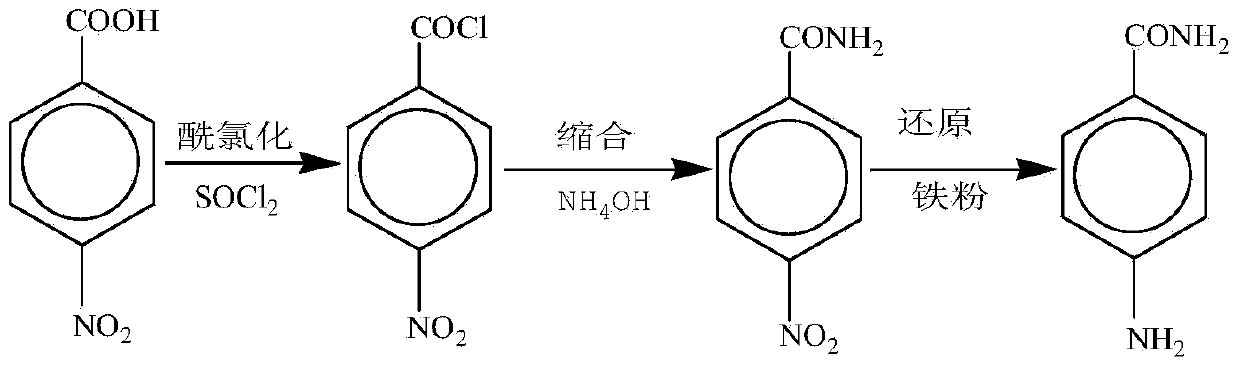

[0044] A preparation method for p-aminobenzamide, comprising the steps of:

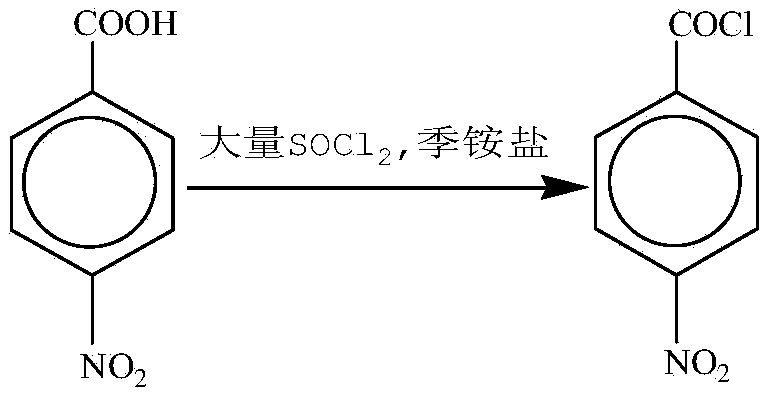

[0045] (1) Preparation of p-nitrobenzoyl chloride: Add 50g of 100% p-nitrobenzoic acid into a 500ml reaction vessel, add 2g of catalyst DMF, inhale 48g of thionyl chloride, start stirring, heat up to 50-60°C, pressure 0.1 React under MPa for 3 hours to obtain p-nitrobenzoyl chloride solution.

[0046] (2) Prepare p-nitrobenzamide: add 165g 20% ammoniacal liquor in 500ml reaction vessel, add step (1) gained p-nitrobenzoyl chloride solution dropwise under pressure 0.1MPa at temperature 15~20 ℃, reaction 4 hour, suction filtration to obtain 48.8 g of p-nitrobenzamide with a purity of 99.1% and a yield of 96.72%. The filtrate is used as a liquid for absorbing waste gas generated by acid chlorination.

[0047] (3) Preparation of p-aminobenzamide: Add 48.8g of p-nitrobenzamide obtained in step (2), 0.5g of ferric hydroxide, 100g of water into a 500ml reaction vessel, start stirring, and add 26g of it dr...

Embodiment 2

[0049]This example provides a kind of preparation method of p-aminobenzamide, which is basically the same as Example 1. The difference is: in the third step of Example 1, p-aminobenzamide was prepared and the filtered mother liquor was used as the bottom water of the reduction reaction to prepare p-aminobenzamide to obtain 38.36 g of p-aminobenzamide, which was a white crystal with a melting point ≥ 182.5°C , with a purity of 99.3% and a yield of 95.5%.

Embodiment 3

[0051] A kind of preparation method of p-aminobenzamide under preferred conditions, it comprises the steps:

[0052] (1) Preparation of p-nitrobenzoyl chloride: Add 50g of 100% p-nitrobenzoic acid into a 500ml reaction vessel, add 1g of catalyst DMF, inhale 48g of thionyl chloride, start stirring, heat up to 75-80°C, pressure 0.2 React under MPa for 3 hours to obtain p-nitrobenzoyl chloride solution.

[0053] (2) Prepare p-nitrobenzamide: add 165g 20% ammoniacal liquor in 500ml reaction vessel, add step (1) gained p-nitrobenzoyl chloride solution dropwise under pressure 0.2MPa at temperature 50~60 DEG C, reaction 4 hours, suction filtration, to obtain p-nitrobenzamide 49.1g, the purity is 99.2%, and the yield is 97.41%. The filtrate is used as a liquid for absorbing waste gas generated by acid chlorination.

[0054] (3) Preparation of p-aminobenzamide: add step (2) gained 49.1g p-nitrobenzamide, 1g ferric hydroxide, 60g water, 50g90% ethanol in a 500ml reaction vessel, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com