A kind of polyethylene glycol monomethyl ether modified mesoporous silica nanoparticles and its preparation method and application

A technology of polyethylene glycol monomethyl ether and mesoporous silica, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

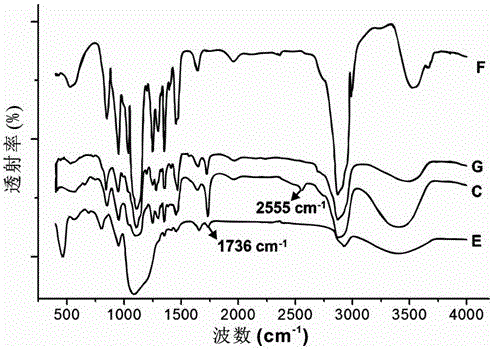

Embodiment 1

[0050] (1) Preparation of polyethylene glycol monomethyl ether acrylate-dithiothreitol

[0051] Polyethylene glycol monomethyl ether (1000, 12.5g, 12.5mmol) was dissolved in 125mL of toluene, argon was passed through, azeotropic distillation was carried out, and about 100mL of toluene was removed. Argon was blown, cooled to room temperature, and then anhydrous dichloromethane was added until the solution was clarified to form a clear solution.

[0052] Triethylamine (2.61mL, 18.75mmol) was added dropwise into the clear solution, and after stirring evenly, 1.60mL of acryloyl chloride (18.75mmol) was added and reacted overnight under nitrogen gas. The product was filtered in vacuo until clear and diethyl ether was added to form a precipitate. The precipitate was collected by filtration and dried in vacuo.

[0053] Dissolve 20 g of the precipitate in 200 mL of deionized water, adjust the pH to 6.0 with NaOH, and extract three times with 100 mL of dichloromethane. Collect the d...

Embodiment 2

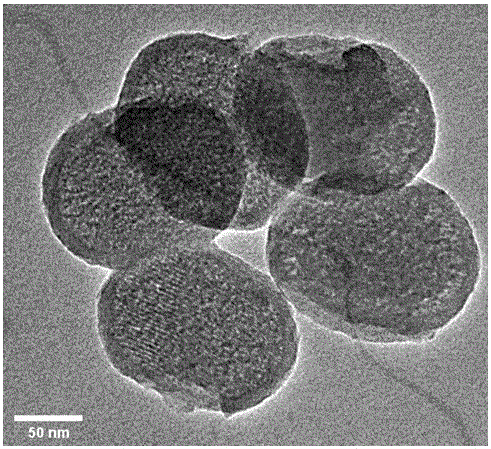

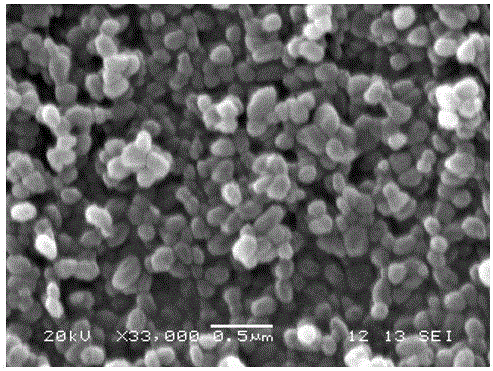

[0061] (1) Preparation of MSNs-SH

[0062] Polyethylene glycol monomethyl ether (20000, 250g, 12.5mmol) was dissolved in 125mL of toluene, argon was passed through, azeotropic distillation was carried out, and about 100mL of toluene was removed. Cool at room temperature with argon gas, cool with ice water, and then add an appropriate amount of anhydrous dichloromethane until the solution is clear to obtain a clear solution.

[0063] Add triethylamine (2.61mL, 18.75mmol) dropwise to the clear solution, stir, then add 3.2mL (37.5mmol) acryloyl chloride, react overnight, blow nitrogen, filter in vacuo until clear, then add diethyl ether to make it Precipitation was collected by filtration and dried in vacuo.

[0064] Dissolve 20 g of the precipitate in 200 mL of deionized water, adjust the pH to 6.0 with NaOH, and extract three times with 100 mL of dichloromethane. The dichloromethane-washed extract was collected, and diethyl ether was added to the extract to form a precipitate...

Embodiment 3

[0072] (1) Preparation of polyethylene glycol monomethyl ether acrylate-dimercapto compound

[0073] Polyethylene glycol monomethyl ether (10000, 125g, 12.5mmol) was dissolved in 125mL of toluene, argon was passed through, azeotropic distillation was carried out, and about 100mL of toluene was removed. Cool at room temperature with argon gas, cool with ice water, and then add an appropriate amount of anhydrous dichloromethane until the solution is clear to obtain a clear solution.

[0074] Triethylamine (2.61 mL, 18.75 mmol) was added dropwise to the clear solution, stirred, and then 1.28 mL (15 mmol) of acryloyl chloride was added, and the reaction was carried out overnight under nitrogen gas. The product was filtered in vacuo until clear and precipitated by addition of diethyl ether. The precipitate was collected by filtration and dried in vacuo.

[0075] Dissolve 20 g of the precipitate in 200 mL of deionized water, adjust the pH to 6.0 with NaOH, and extract three times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com