Ultrahigh-water-resistance coating varnish for artificial stone water transfer printing, and preparation and application methods thereof

A super water-resistant, glossy varnish technology, applied in the field of paint, can solve the problems of poor adhesion, peeling, and cracking of the transfer film, and achieve the effect of strong surface adsorption, improved adhesion, and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

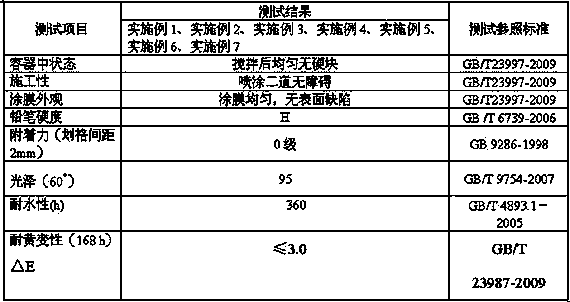

Examples

Embodiment 1

[0040] A super water-resistant artificial stone water transfer printing varnish, in parts by weight, the main paint formula includes the following components: 50 grams of synthetic fatty acid modified alkyd resin; 20 grams of lauric acid modified alkyd resin; 5 grams of ketone resin; 2 grams of nano fumed silica paste; 4 grams of solvent; 0.3 grams of defoaming agent; 0.05 grams of drier; 0.2 grams of leveling agent; 1 gram of adhesion promoter.

[0041] The solid content of the synthetic fatty acid modified alkyd resin is 80 + 2%, acid value ≤10mgKOH / g (60%), OH value 130 + 20 mgKOH / g (100%).

[0042] Lauric acid modified alkyd resin with a solids content of 70 + 2%, acid value ≤12mgKOH / g(60%), OH value 120 + 10 mgKOH / g (100%).

[0043] Aldehyde and ketone resin is solid, the acid value is less than 1mgKOH / g (60%), and the OH value is 55 + 10 mgKOH / g, the softening point is 95±10°C.

[0044] The nano gas phase silica slurry is prepared by refining nano gas phase sili...

Embodiment 2

[0056] A super water-resistant artificial stone water transfer printing varnish, in parts by weight, the main paint formula includes the following components: 52 grams of synthetic fatty acid modified alkyd resin; 21 grams of lauric acid modified alkyd resin; 5.6 grams of ketone resin; 2.5 grams of nano fumed silica slurry; 4.5 grams of solvent; 0.35 grams of defoamer; 0.1 grams of drier; 0.25 grams of leveling agent; 1.5 grams of adhesion promoter.

[0057] The solid content of the synthetic fatty acid modified alkyd resin is 80 + 2%, acid value ≤10mgKOH / g (60%), OH value 130 + 20 mgKOH / g (100%).

[0058] Lauric acid modified alkyd resin with a solids content of 70 + 2%, acid value ≤ 12mgKOH / g (60%), OH value 120 + 10 mgKOH / g (100%).

[0059] Aldehyde and ketone resin is solid, the acid value is less than 1mgKOH / g (60%), and the OH value is 55 + 10 mgKOH / g, the softening point is 95±10℃.

[0060] The nano gas phase silica slurry is prepared by refining nano gas phase...

Embodiment 3

[0072] A super water-resistant artificial stone water transfer printing varnish, in parts by weight, the main paint formula includes the following components: 54 grams of synthetic fatty acid modified alkyd resin; 22 grams of lauric acid modified alkyd resin; 6.2 grams of ketone resin; 3 grams of nano fumed silica slurry; 5 grams of solvent; 0.4 grams of defoamer; 0.15 grams of drier; 0.3 grams of leveling agent; 2 grams of adhesion promoter.

[0073] The solid content of the synthetic fatty acid modified alkyd resin is 80 + 2%, acid value ≤10mgKOH / g (60%), OH value 130 + 20 mgKOH / g (100%).

[0074] Lauric acid modified alkyd resin with a solids content of 70 + 2%, acid value ≤ 12mgKOH / g (60%), OH value 120 + 10 mgKOH / g (100%).

[0075] Aldehyde and ketone resin is solid, the acid value is less than 1mgKOH / g (60%), and the OH value is 55 + 10 mgKOH / g, the softening point is 95±10℃.

[0076] The nano gas phase silica slurry is prepared by refining nano gas phase silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com