Highly-concentrated enzyme-containing liquid detergent free of enzyme stabilizer

A technology of enzyme stabilizer and laundry detergent, which is applied in the field of daily chemical industry, can solve the problems of increasing product cost, harsh environment for protease use, and no contribution of stabilizers, etc., to prolong life, reduce packaging and transportation costs, and enhance detergency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

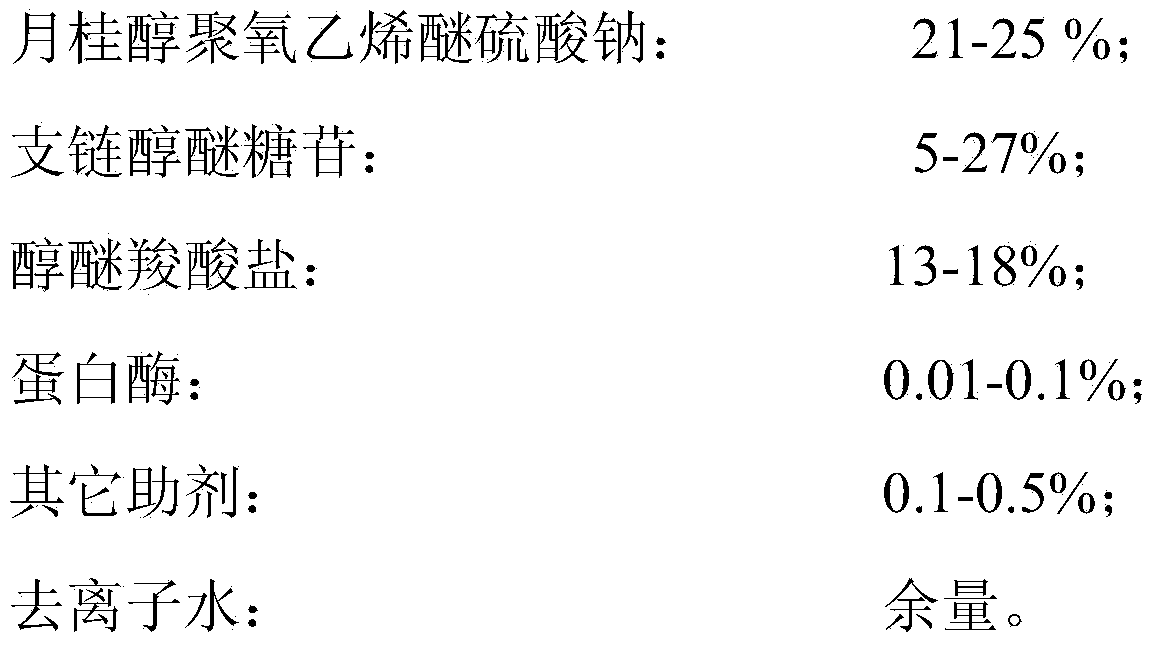

[0022] A highly concentrated enzyme-containing laundry detergent without an enzyme stabilizer is composed of the following components by mass percentage:

[0023]

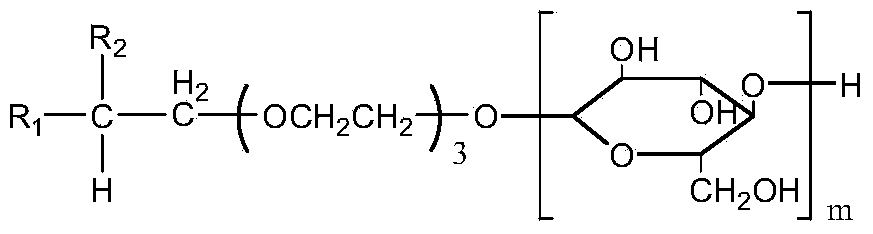

[0024] Among them, the alcohol ether carboxylate carbon chain length is C 12-14 , the adduct number of ethoxy group is 3; the branched chain alcohol ether glycoside has the following structure:

[0025]

[0026] where R 1 is C 4 the alkyl group, R 2 is C 1 The alkyl group, m is 1.3.

Embodiment 2

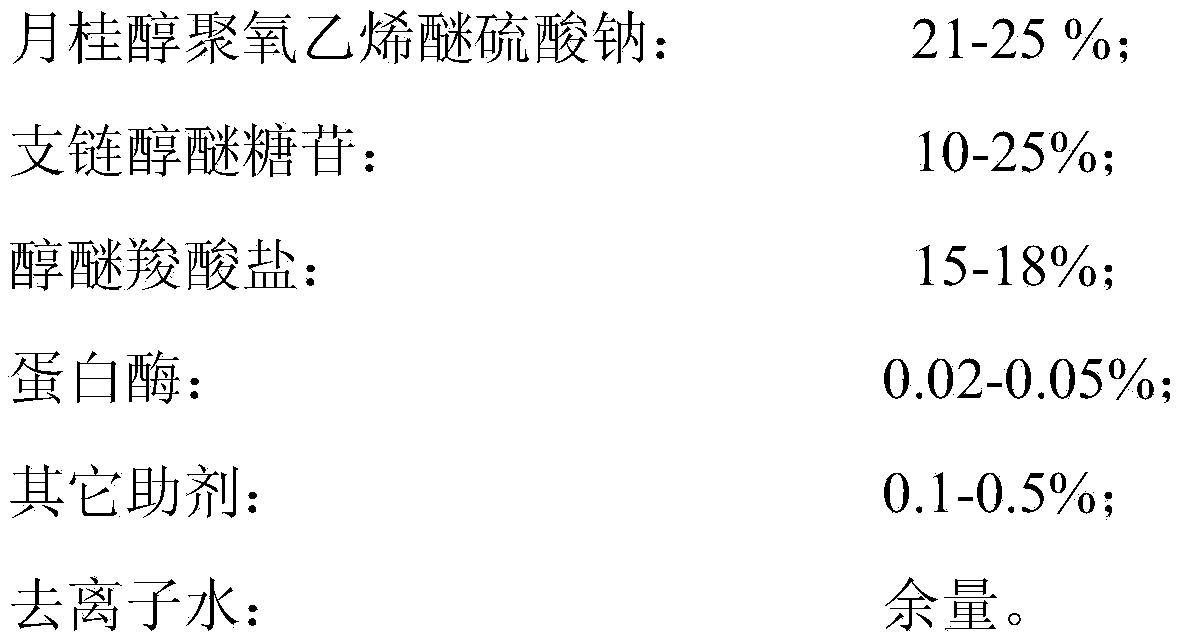

[0028] A highly concentrated enzyme-containing laundry detergent without an enzyme stabilizer is composed of the following components by mass percentage:

[0029]

[0030] Among them, the alcohol ether carboxylate carbon chain length is C 16-18 , the adduct number of ethoxy group is 3; the branched chain alcohol ether glycoside has the following structure:

[0031] where R 1 is C 10 the alkyl group, R 2 is C 4 The alkyl group, m is 1.3.

Embodiment 3

[0033] A highly concentrated enzyme-containing laundry detergent without an enzyme stabilizer is composed of the following components by mass percentage:

[0034]

[0035] Among them, the alcohol ether carboxylate carbon chain length is C 12-14 , the adduct number of ethoxy group is 3; the branched chain alcohol ether glycoside has the following structure:

[0036]

[0037] where R 1 is C 6 the alkyl group, R 2 is C 3 The alkyl group, m is 1.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com