Waste heat comprehensive utilization system of biogas project

An engineering and biogas technology, applied in the fields of gas production bioreactor, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., which can solve the problem that low-grade heat cannot be used, biogas is difficult to guarantee, and the cost is high. problems, to achieve the effect of maintaining a virtuous circle, changing unprofitability and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

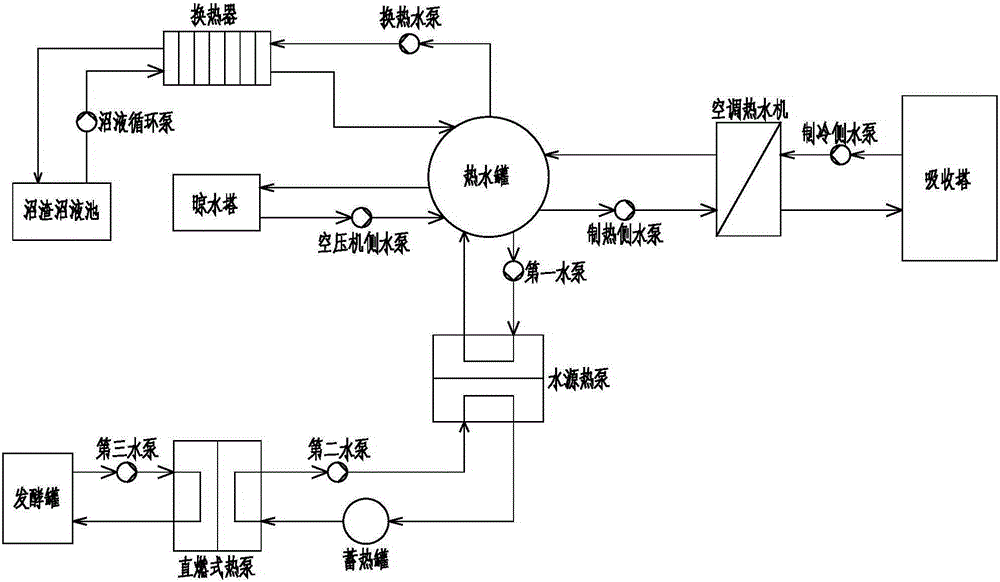

[0016] The waste heat comprehensive utilization system of the biogas project of the present invention, the biogas project includes a fermentation tank, a biogas residue biogas slurry pool, a water drying tower and an absorption tower. The waste heat comprehensive utilization system includes a hot water tank, a heat primary raising system and a heat secondary raising system.

[0017] The primary heat raising system includes a heat exchanger. The biogas residue biogas slurry pool is connected to the water inlet on the heat release side of the heat exchanger through pipelines and a biogas slurry circulation pump, and the water outlet on the heat release side of the heat exchanger is connected to the biogas slurry Slag biogas tank connection; the middle and lower part of the hot water tank is connected to the water inlet provided on the heat-absorbing side of the heat exchanger through the pipeline and the heat exchange pump, and the water outlet provided on the heat-absorbing side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com